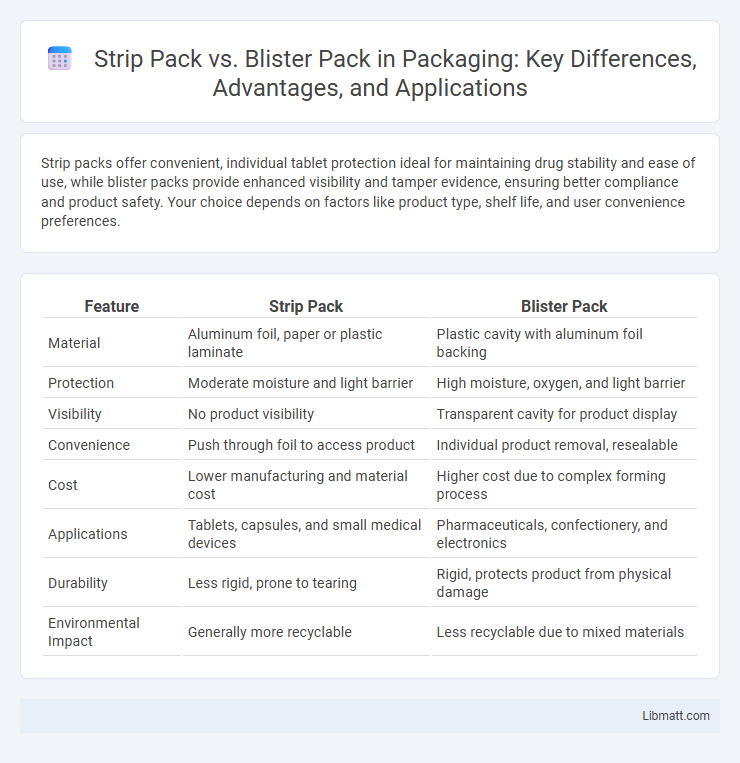

Strip packs offer convenient, individual tablet protection ideal for maintaining drug stability and ease of use, while blister packs provide enhanced visibility and tamper evidence, ensuring better compliance and product safety. Your choice depends on factors like product type, shelf life, and user convenience preferences.

Table of Comparison

| Feature | Strip Pack | Blister Pack |

|---|---|---|

| Material | Aluminum foil, paper or plastic laminate | Plastic cavity with aluminum foil backing |

| Protection | Moderate moisture and light barrier | High moisture, oxygen, and light barrier |

| Visibility | No product visibility | Transparent cavity for product display |

| Convenience | Push through foil to access product | Individual product removal, resealable |

| Cost | Lower manufacturing and material cost | Higher cost due to complex forming process |

| Applications | Tablets, capsules, and small medical devices | Pharmaceuticals, confectionery, and electronics |

| Durability | Less rigid, prone to tearing | Rigid, protects product from physical damage |

| Environmental Impact | Generally more recyclable | Less recyclable due to mixed materials |

Introduction to Strip Pack and Blister Pack

Strip packs and blister packs are common pharmaceutical packaging solutions designed to protect tablets and capsules. Strip packs consist of a series of cavities sealed with a lidding material, typically aluminum foil, offering a compact and cost-effective option for unit-dose packaging. Blister packs feature plastic cavities sealed with foil or plastic lidding, providing enhanced product visibility and protection against moisture and contamination.

Definition and Key Features of Strip Pack

Strip pack is a type of pharmaceutical packaging that consists of tablets or capsules sealed between a lidding foil and a cold-formed aluminum foil or plastic base, offering superior protection against moisture, light, and contamination. This packaging ensures product stability and extended shelf life, making it ideal for sensitive medications. You benefit from easy dose management and tamper-evident features when choosing strip packs over blister packs.

Definition and Key Features of Blister Pack

Blister pack is a packaging format consisting of pre-formed plastic cavities sealed with a lidding material, typically aluminum foil or plastic film, designed to protect individual doses of medication or small consumer goods. Its key features include tamper-evidence, protection from moisture and contamination, ease of dose identification, and convenience for both manufacturers and consumers. Your choice between strip pack and blister pack should consider these benefits, especially if protection and product visibility are critical.

Materials Used in Strip Packing

Strip pack materials typically consist of aluminum foil, paper, and plastic films such as PVC or PVDC, which provide excellent moisture and light protection to preserve product integrity. These multi-layered combinations are engineered to offer barrier properties that extend the shelf life of pharmaceuticals while maintaining flexibility and durability for airtight sealing. Choosing the right materials in your strip packing ensures optimal protection against environmental factors and enhances your product's stability.

Materials Used in Blister Packing

Blister packs typically use a combination of plastic materials like PVC, PET, or PVDC, along with aluminum foil to create a strong, moisture-resistant barrier for pharmaceuticals. These materials ensure product protection from contamination, moisture, and oxygen, preserving the drug's efficacy and extending shelf life. Your choice between strip pack and blister pack may depend on the level of protection required and the specific packaging environment.

Packaging Process: Strip Pack vs Blister Pack

Strip packs involve sealing tablets or capsules between two layers of foil or plastic, allowing for compact, lightweight packaging with simple automated processes. Blister packs use a thermoformed plastic cavity sealed with a foil backing, offering better product protection and visibility but requiring more complex machinery. Your choice depends on factors like product protection needs, packaging speed, and cost-efficiency.

Advantages of Strip Pack

Strip packs protect individual tablets or capsules from moisture, light, and air, ensuring product stability and extended shelf life. Their compact design reduces packaging waste and facilitates easy portability and storage for consumers. Strip packs also allow for tamper-evident features, enhancing medication safety and compliance.

Advantages of Blister Pack

Blister packs offer superior product protection by providing a sealed barrier against moisture, air, and contamination, which extends the shelf life of pharmaceuticals. Their transparent design allows easy visual inspection of each unit, enhancing inventory management and patient compliance. Blister packs also reduce dosage errors by clearly separating individual doses, making them ideal for complex medication regimens.

Limitations and Challenges: Strip Pack vs Blister Pack

Strip packs face limitations such as reduced protection against moisture and air compared to blister packs, increasing the risk of product degradation. Blister packs, while offering superior barrier properties and tamper evidence, can be more costly and less environmentally friendly due to their multi-layer materials. Your choice between strip and blister packs should consider factors like product sensitivity, cost constraints, and sustainability goals.

Choosing the Right Packaging: Factors to Consider

Selecting the right packaging between strip pack and blister pack depends on the product's protection needs, ease of use, and shelf-life requirements. Strip packs offer compact, tamper-evident protection ideal for individual tablets, while blister packs provide enhanced visibility and moisture resistance, suitable for multi-unit products. Your choice should prioritize product stability, consumer convenience, and cost-effectiveness to ensure optimal packaging performance.

Strip pack vs blister pack Infographic

libmatt.com

libmatt.com