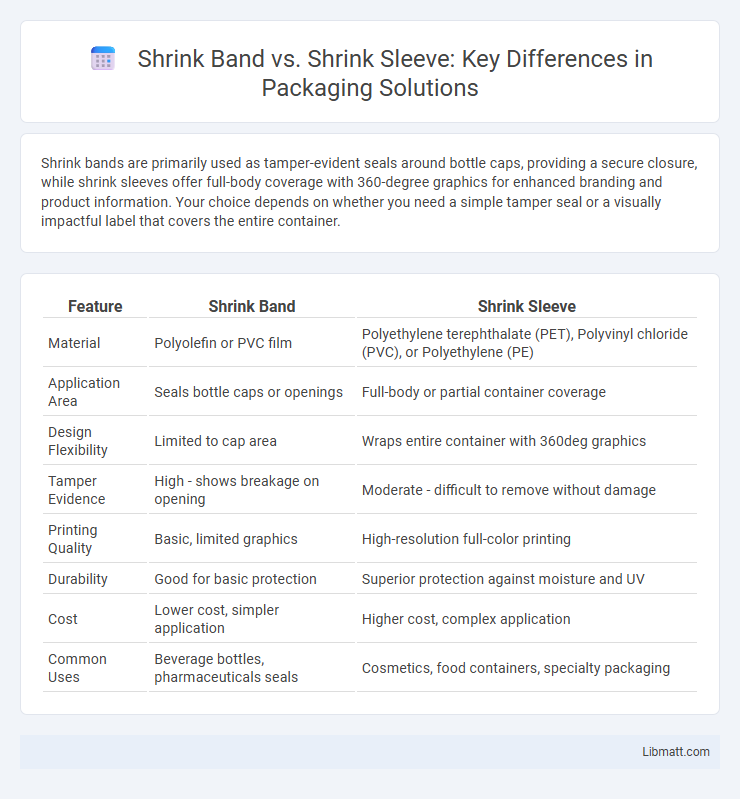

Shrink bands are primarily used as tamper-evident seals around bottle caps, providing a secure closure, while shrink sleeves offer full-body coverage with 360-degree graphics for enhanced branding and product information. Your choice depends on whether you need a simple tamper seal or a visually impactful label that covers the entire container.

Table of Comparison

| Feature | Shrink Band | Shrink Sleeve |

|---|---|---|

| Material | Polyolefin or PVC film | Polyethylene terephthalate (PET), Polyvinyl chloride (PVC), or Polyethylene (PE) |

| Application Area | Seals bottle caps or openings | Full-body or partial container coverage |

| Design Flexibility | Limited to cap area | Wraps entire container with 360deg graphics |

| Tamper Evidence | High - shows breakage on opening | Moderate - difficult to remove without damage |

| Printing Quality | Basic, limited graphics | High-resolution full-color printing |

| Durability | Good for basic protection | Superior protection against moisture and UV |

| Cost | Lower cost, simpler application | Higher cost, complex application |

| Common Uses | Beverage bottles, pharmaceuticals seals | Cosmetics, food containers, specialty packaging |

Understanding Shrink Bands and Shrink Sleeves

Shrink bands are tamper-evident seals made from heat-shrinkable plastic film, commonly used to secure bottle caps and ensure product integrity. Shrink sleeves cover the entire container, providing 360-degree labeling options with vibrant graphics and tamper-evident features. Both technologies utilize heat to conform the film tightly around the product, but shrink sleeves offer more extensive branding opportunities compared to the simpler, functional shrink bands.

Key Differences Between Shrink Band and Shrink Sleeve

Shrink bands primarily provide tamper-evident sealing around bottle caps, ensuring product safety and freshness, while shrink sleeves offer full-body labeling that enhances brand visibility with 360-degree graphics. Shrink sleeves conform tightly to the product's shape, allowing more creative design and marketing opportunities compared to the limited coverage of shrink bands. Your choice depends on whether you prioritize security features or comprehensive branding and aesthetic appeal.

Materials Used in Shrink Packaging Solutions

Shrink bands are typically made from polyvinyl chloride (PVC) or polypropylene (PP), offering strong puncture resistance and clarity for tamper-evident seals. Shrink sleeves use materials like polyolefin, which provide flexibility, superior clarity, and full-body label coverage for branding and protection. Your choice between shrink band and shrink sleeve depends on the packaging requirements and desired material properties in shrink packaging solutions.

Application Methods: Shrink Band vs. Shrink Sleeve

Shrink bands are typically applied using heat guns or heat tunnels that activate the adhesive and shrink the band tightly around the product neck or cap, providing tamper evidence. Shrink sleeves require specialized shrink sleeve applicators that position the full-body label before exposing it to heat tunnels or steam to conform fully to the container shape. Both methods rely on controlled thermal activation but differ in equipment complexity and coverage area, with shrink sleeves offering full 360-degree decoration and shrink bands providing localized security seals.

Functional Benefits of Each Shrink Technology

Shrink bands provide tamper-evident seals that ensure product integrity and enhance consumer safety, making them ideal for caps and closures. Shrink sleeves offer 360-degree brand visibility with full-color graphics, boosting shelf appeal and marketing impact. Your choice depends on whether security or visual branding is the primary functional benefit needed for your packaging.

Branding and Design Opportunities

Shrink bands offer limited branding space, primarily serving as tamper-evident seals with minimal design flexibility. Shrink sleeves provide full 360-degree coverage, allowing vibrant, high-resolution graphics and seamless branding opportunities that enhance product visibility. Your choice impacts how effectively you communicate brand identity through packaging design.

Tamper Evidence: A Comparative Analysis

Shrink bands provide a secure tamper-evident seal by tightly encircling bottle necks, making any unauthorized access visually obvious through band breakage. Shrink sleeves offer comprehensive tamper evidence with full-body coverage, allowing for customized graphics and easy detection of tampering anywhere on the container. Ultimately, shrink sleeves deliver enhanced brand protection by combining tamper evidence with high visibility and design flexibility.

Cost Considerations and Efficiency

Shrink bands generally offer lower initial costs due to simpler application equipment and minimal material usage, making them cost-effective for smaller production runs. Shrink sleeves, while requiring higher upfront investment in specialized machinery and more material, provide greater efficiency in high-volume packaging through faster application speeds and comprehensive label coverage. Your choice should balance budget constraints against production scale to optimize cost efficiency.

Industry-Specific Applications

Shrink bands are widely used in the pharmaceutical and food industries for tamper-evident sealing on bottles and jars, ensuring product safety and compliance with regulatory standards. Shrink sleeves offer full-body coverage and vibrant graphics, making them ideal for beverage packaging, cosmetics, and household products that require 360-degree branding and protection. Both solutions enhance product integrity but differ in application versatility based on industry-specific packaging requirements.

Choosing the Right Option for Your Product

Choosing the right option between shrink band and shrink sleeve depends on product protection and branding needs. Shrink bands provide tamper-evident security and are ideal for sealing bottle caps, while shrink sleeves offer 360-degree full-body labeling with vibrant graphics for enhanced shelf appeal. Evaluating factors like container shape, marketing goals, and budget ensures optimal packaging performance and consumer attraction.

Shrink band vs shrink sleeve Infographic

libmatt.com

libmatt.com