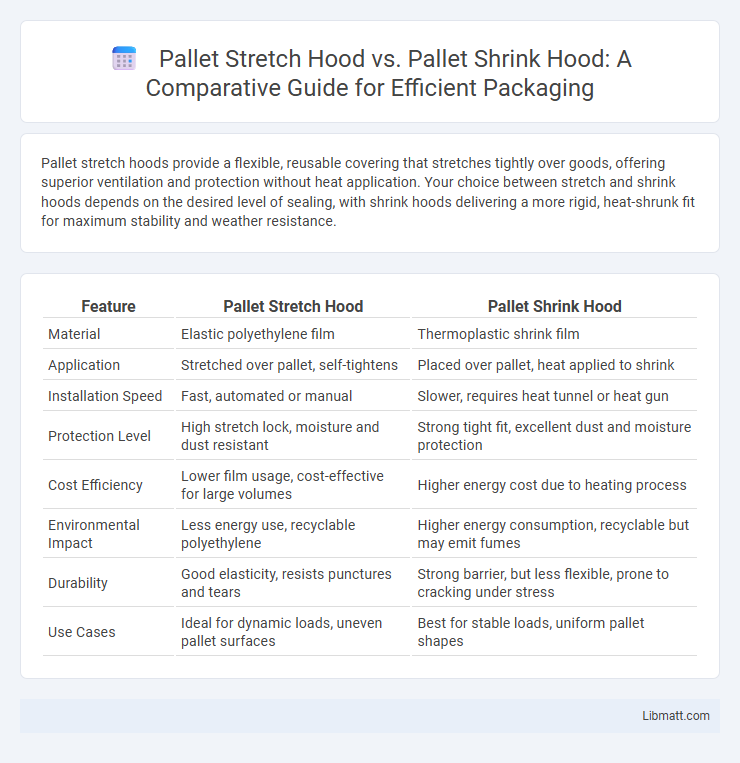

Pallet stretch hoods provide a flexible, reusable covering that stretches tightly over goods, offering superior ventilation and protection without heat application. Your choice between stretch and shrink hoods depends on the desired level of sealing, with shrink hoods delivering a more rigid, heat-shrunk fit for maximum stability and weather resistance.

Table of Comparison

| Feature | Pallet Stretch Hood | Pallet Shrink Hood |

|---|---|---|

| Material | Elastic polyethylene film | Thermoplastic shrink film |

| Application | Stretched over pallet, self-tightens | Placed over pallet, heat applied to shrink |

| Installation Speed | Fast, automated or manual | Slower, requires heat tunnel or heat gun |

| Protection Level | High stretch lock, moisture and dust resistant | Strong tight fit, excellent dust and moisture protection |

| Cost Efficiency | Lower film usage, cost-effective for large volumes | Higher energy cost due to heating process |

| Environmental Impact | Less energy use, recyclable polyethylene | Higher energy consumption, recyclable but may emit fumes |

| Durability | Good elasticity, resists punctures and tears | Strong barrier, but less flexible, prone to cracking under stress |

| Use Cases | Ideal for dynamic loads, uneven pallet surfaces | Best for stable loads, uniform pallet shapes |

Introduction to Pallet Stretch Hood and Pallet Shrink Hood

Pallet stretch hoods utilize elastic polyethylene films that stretch when applied over a pallet, providing a secure and reusable protective cover that adapts to different load shapes. Pallet shrink hoods, made from heat-responsive shrink films, conform tightly around goods after heat application, offering a more rigid and tamper-evident packaging solution. You can choose between these two based on your specific protection needs, load stability, and environmental considerations.

How Pallet Stretch Hood Works

Pallet stretch hood uses highly elastic polyethylene film that stretches over the pallet and then retracts to create a snug, protective cover. This tight fit provides excellent load stability, protects against dust and moisture, and adapts to pallet shape variations, enhancing transport safety and storage efficiency. You benefit from faster application and reduced film waste compared to traditional pallet shrink hood methods, which require heat to shrink the film.

How Pallet Shrink Hood Works

Pallet shrink hoods work by tightly wrapping a plastic film around the palletized goods, then applying heat which causes the film to contract and conform tightly to the shape of the load. This heat-induced shrinking action creates a secure, protective barrier that stabilizes the pallet, resists moisture, dust, and damage during transportation. Your choice between pallet shrink hood and stretch hood depends on factors like load shape, handling requirements, and environmental exposure.

Material Comparison: Stretch Hood vs Shrink Hood

Stretch hoods are typically made from highly elastic polyethylene that conforms tightly to pallet loads by stretching over the product, providing superior containment and protection against dust, moisture, and UV light. Shrink hoods use thicker, less elastic polyethylene film that requires heat application to shrink and tightly wrap around the pallet, creating a rigid, stable covering. Choosing between stretch and shrink hoods depends on your needs for application speed, film strength, and the environmental conditions your palletized goods will face.

Application Industries for Each Hood Type

Pallet stretch hoods are widely used in industries such as agriculture, construction, and manufacturing, where protection against moisture, dust, and damage during transportation is crucial. Pallet shrink hoods find applications in food and beverage, pharmaceuticals, and electronics industries, offering a tighter, more secure fit that enhances load stability and contamination prevention. Your choice between these hoods should align with your industry's specific packaging and protection requirements.

Packaging Efficiency and Speed

Pallet stretch hoods offer superior packaging efficiency by conforming tightly to loads with minimal material waste, enabling faster wrap cycles through automatic stretch hood machines. Pallet shrink hoods require heat application to shrink the film, which extends packaging time and energy consumption but provides excellent protection against moisture and dust. Stretch hood technology is generally preferred for high-speed operations due to its rapid application and consistent load stability without the need for drying or cooling periods.

Cost Analysis: Stretch Hood vs Shrink Hood

Stretch hoods typically offer lower operational costs due to faster application speeds and reduced energy consumption compared to shrink hoods, which require heat guns or tunnels for sealing. Material costs for stretch hoods are often less expensive because the film is designed to stretch and conform tightly without the need for additional heat-tightening processes. While initial equipment investment for shrink hood systems can be lower, the ongoing expenses for energy and maintenance tend to make stretch hoods more cost-effective over time for high-volume packaging.

Protection and Load Stability Features

Pallet stretch hoods provide superior load stability by creating a tight, elastic fit that absorbs shocks and prevents movement during transport, enhancing protection against dust, moisture, and UV damage. Pallet shrink hoods offer excellent protection by conforming closely to the pallet's shape when heat is applied, forming a rigid barrier that secures irregular loads and shields against external contaminants. Your choice between these options depends on the need for load flexibility with stretch hoods or the rigid, form-fitting security of shrink hoods for fragile or unstable cargo.

Sustainability and Environmental Impact

Pallet stretch hoods use less plastic material compared to pallet shrink hoods, significantly reducing plastic waste and energy consumption during application. Stretch hoods eliminate the need for heat, decreasing greenhouse gas emissions and improving workplace safety by avoiding heat-related risks. The reusable nature of stretch hoods also enhances circular economy benefits, making them a more sustainable packaging solution than single-use shrink hoods.

Choosing the Best Option for Your Pallet Packaging Needs

Pallet stretch hoods provide superior load stability and weather resistance by tightly covering pallets with stretchable, UV-resistant film that adapts to various shapes and sizes. Pallet shrink hoods use heat to conform plastic film around pallets, offering excellent protection but requiring additional energy and equipment for application. Selecting the best option depends on budget, environmental conditions, and load characteristics, with stretch hoods preferred for faster, reusable solutions and shrink hoods favored for a sealed, tamper-evident finish.

Pallet stretch hood vs pallet shrink hood Infographic

libmatt.com

libmatt.com