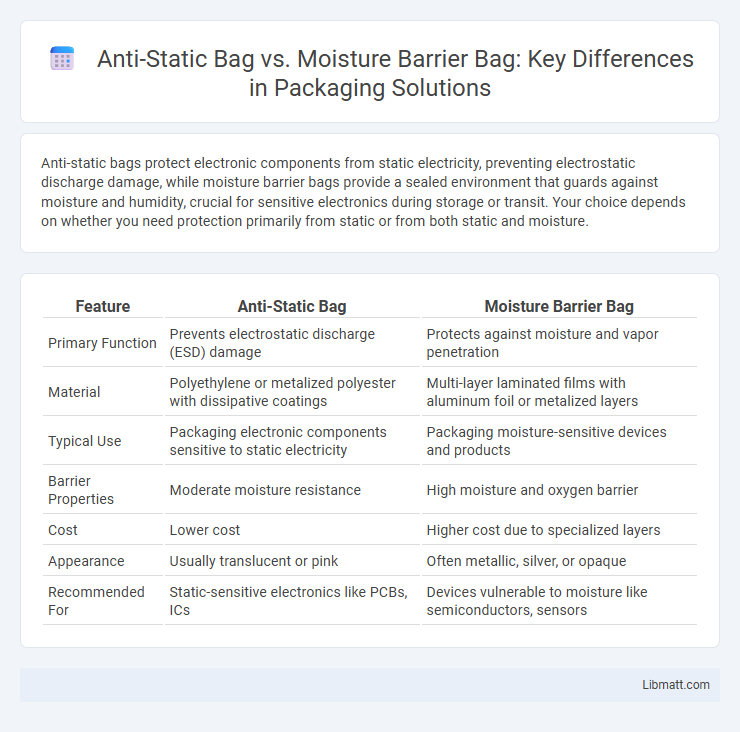

Anti-static bags protect electronic components from static electricity, preventing electrostatic discharge damage, while moisture barrier bags provide a sealed environment that guards against moisture and humidity, crucial for sensitive electronics during storage or transit. Your choice depends on whether you need protection primarily from static or from both static and moisture.

Table of Comparison

| Feature | Anti-Static Bag | Moisture Barrier Bag |

|---|---|---|

| Primary Function | Prevents electrostatic discharge (ESD) damage | Protects against moisture and vapor penetration |

| Material | Polyethylene or metalized polyester with dissipative coatings | Multi-layer laminated films with aluminum foil or metalized layers |

| Typical Use | Packaging electronic components sensitive to static electricity | Packaging moisture-sensitive devices and products |

| Barrier Properties | Moderate moisture resistance | High moisture and oxygen barrier |

| Cost | Lower cost | Higher cost due to specialized layers |

| Appearance | Usually translucent or pink | Often metallic, silver, or opaque |

| Recommended For | Static-sensitive electronics like PCBs, ICs | Devices vulnerable to moisture like semiconductors, sensors |

Understanding Anti-Static Bags: Key Features

Anti-static bags are designed with a metallized or conductive layer that prevents electrostatic discharge (ESD) from damaging sensitive electronic components during storage and transportation. These bags provide a controlled environment by dissipating static electricity while allowing moisture to pass through, making them ideal for short-term protection. Compared to moisture barrier bags, which seal out humidity and oxygen to prevent corrosion, anti-static bags primarily focus on ESD prevention without offering comprehensive moisture protection.

What Are Moisture Barrier Bags?

Moisture barrier bags are specialized packaging designed to protect sensitive electronic components from humidity, moisture, and corrosion by creating a sealed environment with low water vapor transmission rates. These bags typically feature multiple layers of laminated materials, including aluminum foil, which provides superior moisture resistance compared to standard anti-static bags that primarily block static electricity. Moisture barrier bags are essential in industries requiring long-term storage or shipping of moisture-sensitive devices, ensuring component reliability and longevity.

How Anti-Static Bags Protect Electronics

Anti-static bags protect electronics by dissipating static electricity that can damage sensitive components during handling and transportation. These bags are made from polyethylene or metallized polyester materials that inhibit electrostatic discharge (ESD) through conductive or dissipative layers. Unlike moisture barrier bags, anti-static bags do not provide significant protection against humidity or moisture, focusing primarily on preventing static-related damage.

Moisture Barrier Bags: Protection from Environmental Hazards

Moisture barrier bags offer superior protection against environmental hazards by preventing moisture, oxygen, and contaminants from reaching sensitive electronic components. These bags typically feature multiple layers, including metalized films, to provide an effective barrier against humidity and static discharge. Their ability to maintain low moisture vapor transmission rates (MVTR) ensures long-term preservation and reliability of stored devices.

Material Composition: Anti-Static vs Moisture Barrier Bags

Anti-static bags are typically made from polyethylene or polypropylene with a static dissipative coating that prevents electrostatic discharge, while moisture barrier bags consist of multiple layers, including a metallized film like aluminum foil, to provide an impermeable shield against moisture and oxygen. The material composition of moisture barrier bags offers superior protection against humidity and corrosion, making them ideal for sensitive electronics and long-term storage. Your choice between the two should depend on whether electrostatic protection or moisture resistance is the primary concern for your components.

Application Scenarios: When to Use Each Bag

Anti-static bags are ideal for protecting sensitive electronic components such as circuit boards, processors, and memory devices from electrostatic discharge during transportation and storage. Moisture barrier bags are essential when high humidity or moisture exposure poses a risk, commonly used for storing delicate semiconductor devices, PCBs, and other moisture-sensitive components. Choose anti-static bags for static protection needs and moisture barrier bags when environmental moisture control is critical to prevent corrosion or failure.

Static Discharge Risks and Prevention

Anti-static bags reduce static electricity by preventing charge buildup, making them suitable for protecting sensitive electronics during handling and transport. Moisture barrier bags provide a sealed environment that blocks moisture and oxygen, preventing corrosion but offering limited protection against static discharge. For comprehensive electrical component safety, your choice should prioritize anti-static properties to mitigate static discharge risks effectively.

Moisture Damage Risks and Solutions

Moisture barrier bags provide superior protection against moisture damage by incorporating multiple layers of polyethylene, aluminum foil, and other materials to create a moisture-resistant seal, essential for preserving sensitive electronic components. Anti-static bags primarily prevent electrostatic discharge but offer limited defense against humidity, making them insufficient for environments with high moisture exposure. To effectively mitigate moisture damage risks, moisture barrier bags with desiccants offer an optimal solution by maintaining low humidity levels and preventing corrosion or degradation of stored items.

Cost Comparison: Anti-Static Bag vs Moisture Barrier Bag

Anti-static bags typically cost less than moisture barrier bags due to simpler materials and manufacturing processes. Moisture barrier bags, designed with multiple layers to prevent water vapor and static, demand higher production costs which reflect in their price. Your choice depends on budget constraints and the level of protection needed for sensitive electronic components.

Choosing the Right Packaging for Sensitive Components

Selecting the right packaging for sensitive components hinges on their specific protection needs, with anti-static bags preventing electrostatic discharge (ESD) damage and moisture barrier bags shielding against humidity and corrosion. Anti-static bags are made from materials that dissipate static electricity, ideal for electronic devices sensitive to static shocks. Moisture barrier bags incorporate aluminum foil or other impermeable layers, creating a sealed environment that protects components from moisture, oxidation, and contamination during storage and transport.

Anti-static bag vs moisture barrier bag Infographic

libmatt.com

libmatt.com