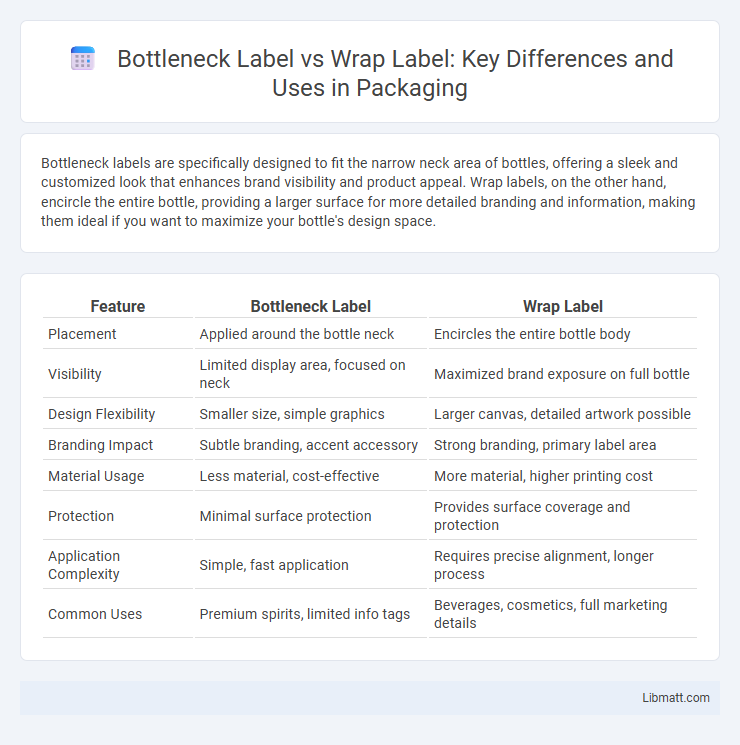

Bottleneck labels are specifically designed to fit the narrow neck area of bottles, offering a sleek and customized look that enhances brand visibility and product appeal. Wrap labels, on the other hand, encircle the entire bottle, providing a larger surface for more detailed branding and information, making them ideal if you want to maximize your bottle's design space.

Table of Comparison

| Feature | Bottleneck Label | Wrap Label |

|---|---|---|

| Placement | Applied around the bottle neck | Encircles the entire bottle body |

| Visibility | Limited display area, focused on neck | Maximized brand exposure on full bottle |

| Design Flexibility | Smaller size, simple graphics | Larger canvas, detailed artwork possible |

| Branding Impact | Subtle branding, accent accessory | Strong branding, primary label area |

| Material Usage | Less material, cost-effective | More material, higher printing cost |

| Protection | Minimal surface protection | Provides surface coverage and protection |

| Application Complexity | Simple, fast application | Requires precise alignment, longer process |

| Common Uses | Premium spirits, limited info tags | Beverages, cosmetics, full marketing details |

Introduction to Bottleneck Labels and Wrap Labels

Bottleneck labels adhere seamlessly to the narrow, curved neck area of bottles, enhancing brand visibility and providing a sophisticated look without compromising the bottle's design. Wrap labels, in contrast, fully encircle the bottle, allowing for larger, continuous graphics and detailed product information, ideal for creating a strong shelf presence. You can choose between these label types based on the bottle shape and marketing goals to optimize product appeal and consumer engagement.

Key Differences Between Bottleneck Labels and Wrap Labels

Bottleneck labels are specifically designed to fit the narrow neck area of bottles, offering a sleek and targeted branding space, whereas wrap labels cover the entire circumference of the bottle, providing a larger surface area for detailed graphics and information. Bottleneck labels are typically smaller and used to highlight logos or seal branding, while wrap labels encompass the whole body, allowing for comprehensive product descriptions and marketing elements. The choice between these labels depends on branding goals, with bottleneck labels enhancing elegance and wrap labels maximizing visual impact.

Materials Commonly Used in Bottleneck and Wrap Labels

Bottleneck labels typically use materials like polypropylene, polypropylene shrink sleeves, or PVC films to provide durability and flexibility for curved surfaces. Wrap labels often employ paper, BOPP (biaxially oriented polypropylene), or PET (polyethylene terephthalate) for a smooth, continuous design around the container. Your choice of materials impacts the label's resistance to moisture, temperature, and abrasion, influencing both functionality and aesthetics.

Design Flexibility: Bottleneck vs Wrap Label

Bottleneck labels offer limited design space confined to the narrow neck of the bottle, making them ideal for simple logos or product information without overwhelming the overall look. Wrap labels provide extensive design flexibility by covering the entire bottle, allowing for vibrant, detailed artwork and branding that enhances shelf appeal. Your choice depends on how much visual storytelling and product detail you want to communicate on the packaging.

Branding Opportunities for Bottleneck and Wrap Label

Bottleneck labels enhance branding opportunities by providing a unique, eye-catching placement around the neck of the bottle, allowing Your product to stand out on crowded shelves with limited space for branding. Wrap labels offer a larger surface area, enabling comprehensive design elements and detailed brand storytelling that captivates consumers and boosts brand recognition. Both label types play vital roles in product differentiation, yet bottleneck labels excel in adding a premium touch, while wrap labels maximize visual impact through extensive branding coverage.

Cost Comparison: Bottleneck Label vs Wrap Label

Bottleneck labels generally incur higher costs than wrap labels due to their specialized design, requiring precise application on narrow bottle necks and often involving more complex machinery. Wrap labels offer a cost-effective solution by covering larger surface areas with simpler application processes, reducing material waste and labor expenses. Choosing the right label depends on balancing your budget constraints against the desired aesthetic and functional quality of your product packaging.

Application Processes: Bottleneck Label vs Wrap Label

Bottleneck labels are primarily applied through high-speed pressure-sensitive labeling machines, allowing precise placement on narrow necks of bottles, making them ideal for branding and compliance information on beverage and pharmaceutical containers. Wrap labels utilize shrink or stretch sleeve application processes where the label fully encases the product, offering 360-degree branding and tamper-evident features often used in cosmetic and food industries. Both application processes require calibrated machinery but differ significantly in their labeling speed, material flexibility, and suitability to container shapes and sizes.

Shelf Impact and Consumer Appeal

Bottleneck labels provide a streamlined, elegant appearance that enhances shelf impact by hugging the bottle's neck, making products easily identifiable and creating a premium look. Wrap labels cover the entire bottle surface, offering maximum branding space for vibrant, detailed designs that attract consumer attention and convey complex messaging. While bottleneck labels emphasize sophistication and subtlety, wrap labels deliver bold visual appeal and extensive information, optimizing consumer engagement and shelf visibility.

Sustainability Considerations for Label Types

Bottleneck labels typically use less material and adhesive, reducing waste and environmental impact compared to full-wrap labels that cover the entire bottle. Wrap labels, often made of plastic films, may pose recycling challenges due to difficulty separating them from the bottle, whereas bottleneck labels are easier to remove and recycle. Choosing bottleneck labels can enhance a product's sustainability profile by supporting circular economy goals and minimizing plastic use.

Choosing the Right Label: Bottleneck or Wrap Label?

Choosing the right label depends on the bottle shape and branding goals; bottleneck labels are designed to fit snugly around the neck of bottles, providing a premium look and highlighting brand identity in a compact area. Wrap labels cover the full circumference of the bottle, offering maximum space for detailed artwork, product information, and promotional messages. Consider the target market and packaging style to determine whether the elegance of a bottleneck label or the extensive visual impact of a wrap label will better enhance product appeal and shelf presence.

Bottleneck label vs wrap label Infographic

libmatt.com

libmatt.com