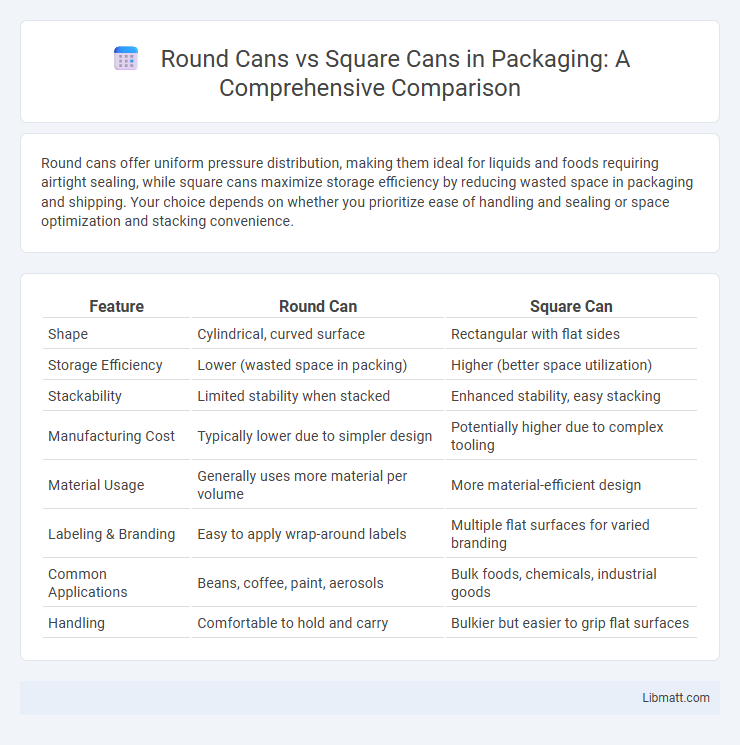

Round cans offer uniform pressure distribution, making them ideal for liquids and foods requiring airtight sealing, while square cans maximize storage efficiency by reducing wasted space in packaging and shipping. Your choice depends on whether you prioritize ease of handling and sealing or space optimization and stacking convenience.

Table of Comparison

| Feature | Round Can | Square Can |

|---|---|---|

| Shape | Cylindrical, curved surface | Rectangular with flat sides |

| Storage Efficiency | Lower (wasted space in packing) | Higher (better space utilization) |

| Stackability | Limited stability when stacked | Enhanced stability, easy stacking |

| Manufacturing Cost | Typically lower due to simpler design | Potentially higher due to complex tooling |

| Material Usage | Generally uses more material per volume | More material-efficient design |

| Labeling & Branding | Easy to apply wrap-around labels | Multiple flat surfaces for varied branding |

| Common Applications | Beans, coffee, paint, aerosols | Bulk foods, chemicals, industrial goods |

| Handling | Comfortable to hold and carry | Bulkier but easier to grip flat surfaces |

Introduction to Round Cans vs Square Cans

Round cans offer a classic, efficient design widely used for beverages and food packaging due to their ease of manufacturing and stacking. Square cans provide a space-saving alternative with better shelf utilization and reduced packaging material waste. Choosing between round and square cans impacts your product's branding, storage efficiency, and environmental footprint.

Historical Evolution of Can Shapes

Round cans dominated early packaging due to straightforward metal forming techniques established in the 19th century, facilitating efficient mass production and sealing. Square cans emerged in the mid-20th century as a response to storage and shipping inefficiencies, offering improved space utilization and stacking capabilities. Advances in manufacturing technology enabled the widespread adoption of square cans, balancing material use with functionality in modern supply chains.

Material Efficiency and Waste Reduction

Square cans offer superior material efficiency compared to round cans due to their ability to fit together without wasted space, maximizing storage and transportation capacity. The geometric design of square cans reduces the amount of packaging material required per unit of volume, directly contributing to waste reduction. This optimized use of materials results in a more sustainable packaging solution, minimizing environmental impact throughout the supply chain.

Storage and Space Optimization

Square cans offer superior storage and space optimization compared to round cans due to their ability to fit snugly side by side without wasted gaps. This shape maximizes shelf and shipping space, reducing packaging costs and environmental impact. Round cans, while easier to manufacture and better for pressure distribution, often result in less efficient storage and higher transportation space utilization.

Manufacturing and Production Costs

Round cans generally have lower manufacturing and production costs due to their simpler design, which allows for faster forming and sealing processes. Square cans require more precise cutting and corner reinforcement, leading to higher material wastage and increased labor expenses. Your choice between round and square cans impacts overall production efficiency and cost-effectiveness.

Transportation and Distribution Benefits

Round cans offer enhanced transportation efficiency due to their uniform shape, minimizing damage risks by evenly distributing pressure during transit. Square cans optimize storage space in distribution by maximizing pallet utilization and reducing gaps, leading to cost savings. Your choice between round and square cans impacts logistical efficiency and overall supply chain performance.

Consumer Appeal and Product Presentation

Round cans offer a classic and visually appealing shape that fits comfortably in consumers' hands, enhancing the tactile experience and promoting brand recognition through smooth, continuous labels. Square cans maximize shelf space efficiency, allowing for bolder, more structured graphics that capture consumer attention and create a modern, premium product presentation. Both shapes influence purchase decisions by balancing ergonomic comfort with impactful visual merchandising in retail environments.

Functional Performance and Usability

Round cans offer superior structural integrity and uniform pressure distribution, enhancing durability during transportation and storage. Square cans maximize space efficiency by allowing tighter packing and reduced wasted volume in storage and shipping, improving usability in logistics. However, round cans provide easier stacking stability and ergonomic handling, benefiting end-user convenience.

Environmental Impact and Recycling

Round cans typically have higher recycling rates due to their uniform shape, which facilitates efficient sorting and processing in recycling facilities. Square cans, while offering better space utilization during transportation and storage, often face challenges in standard recycling streams, potentially increasing their environmental footprint. Choosing round cans generally supports better environmental outcomes by enhancing recyclability and reducing waste contamination.

Choosing the Right Can Shape for Your Product

Selecting the right can shape depends on your product's storage, shelf appeal, and packaging efficiency. Round cans are ideal for liquids and easy handling, while square cans maximize space and reduce shipping costs. Your choice affects product protection, branding impact, and overall customer experience.

Round can vs square can Infographic

libmatt.com

libmatt.com