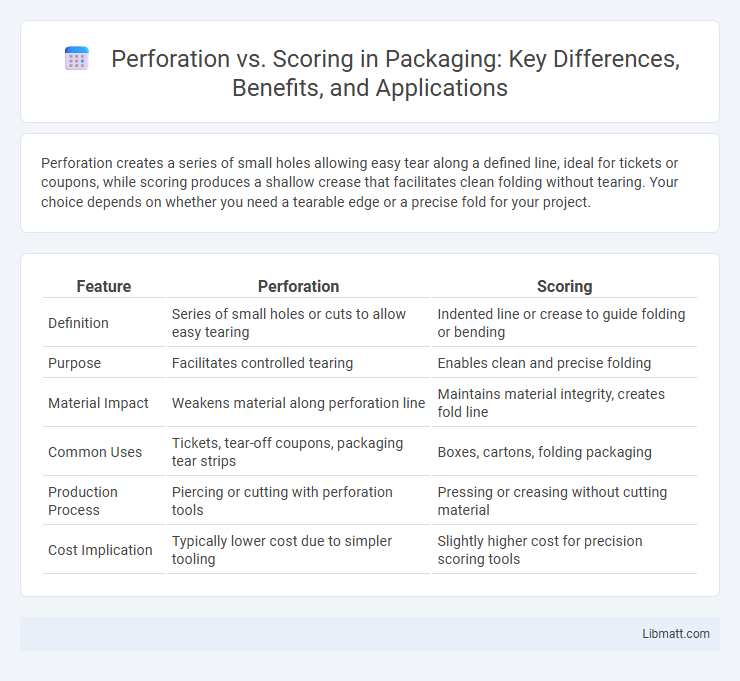

Perforation creates a series of small holes allowing easy tear along a defined line, ideal for tickets or coupons, while scoring produces a shallow crease that facilitates clean folding without tearing. Your choice depends on whether you need a tearable edge or a precise fold for your project.

Table of Comparison

| Feature | Perforation | Scoring |

|---|---|---|

| Definition | Series of small holes or cuts to allow easy tearing | Indented line or crease to guide folding or bending |

| Purpose | Facilitates controlled tearing | Enables clean and precise folding |

| Material Impact | Weakens material along perforation line | Maintains material integrity, creates fold line |

| Common Uses | Tickets, tear-off coupons, packaging tear strips | Boxes, cartons, folding packaging |

| Production Process | Piercing or cutting with perforation tools | Pressing or creasing without cutting material |

| Cost Implication | Typically lower cost due to simpler tooling | Slightly higher cost for precision scoring tools |

Introduction to Perforation and Scoring

Perforation and scoring are essential techniques in paper and packaging industries to enhance product usability by facilitating easy folding or tearing. Perforation involves creating a series of small holes or cuts in a material, enabling clean and controlled separation, while scoring refers to making a shallow crease to guide precise folding without damaging the substrate. Understanding these methods helps you choose the right process for improving packaging functionality and user experience.

Definition of Perforation

Perforation refers to the process of creating a series of small holes or punctures in a material, typically paper or film, to enable easy tearing or separation along a specified line. This technique is commonly used in products such as postage stamps, tickets, and packaging to facilitate clean and controlled detachment. The precision and spacing of perforations are critical factors that influence the ease of tearing and overall functionality.

Definition of Scoring

Scoring is a technique that involves creating a shallow cut or groove on the surface of a material to facilitate controlled folding or breaking. Unlike perforation, which consists of a series of small holes or punctures, scoring weakens the material along a precise line without fully penetrating it. This method is commonly used in packaging, paper crafts, and drywall installation to ensure clean, accurate bends or separations.

Key Differences Between Perforation and Scoring

Perforation involves creating a series of small holes or cuts to facilitate clean and easy tearing along a designated line, commonly used in paper, packaging, and stamps. Scoring, on the other hand, refers to making a shallow crease or groove on materials like paper, cardboard, or metal to enable precise folding without cracking or damage. Understanding these key differences helps you choose the appropriate technique for your project, ensuring optimal functionality and presentation.

Common Applications of Perforation

Perforation is widely used in applications such as postage stamps, tickets, and packaging to enable easy separation of individual sections. Its precise holes create tear lines that enhance functionality while maintaining product integrity. Your ability to quickly detach parts without damaging the material makes perforation ideal for consumer convenience and industrial processes.

Typical Uses of Scoring

Scoring is typically used to create precise fold lines in materials such as paper, cardboard, and sheet metal, facilitating easier and cleaner bending without cracking. Common applications include packaging design, where scored lines allow boxes or cartons to fold accurately during assembly. Scoring also aids in producing foldable brochures, envelopes, and decorative items by enabling consistent and controlled creasing.

Materials Suitable for Perforation and Scoring

Perforation is ideal for materials like paper, cardboard, and thin plastic films, allowing easy separation without damaging the substrate. Scoring works best on thicker materials such as corrugated board, chipboard, and heavy cardstock, creating a fold line without cracking or breaking. Both techniques optimize convertibility and usability depending on material thickness and desired end-use.

Advantages and Disadvantages of Each Method

Perforation offers precise separation lines ideal for easy tearing in packaging, reducing waste and improving user convenience, but its production can increase manufacturing costs and weaken material strength. Scoring creates a crease that facilitates folding without damaging the material, enhancing design flexibility and structural integrity, yet it may require additional processing and might not allow as clean a separation as perforation. Your choice depends on balancing ease of use, production efficiency, and the specific functional requirements of the final product.

Choosing Between Perforation and Scoring

Choosing between perforation and scoring depends on the material thickness, desired tear precision, and end-use application. Perforation creates a series of small holes allowing easy tearing, ideal for paper products or tickets, while scoring produces a crease for clean folding, suitable for cardboard or thicker substrates. Your decision should balance ease of use with the structural integrity required for packaging or printed materials.

Summary and Recommendations

Perforation creates a series of small holes to facilitate easy tearing, ideal for packaging and ticket printing, while scoring produces a crease for precise folding without breaking the material, suitable for cartons and brochures. For applications requiring durability with clean folds, scoring is recommended, whereas perforation is best for items needing quick separation or portioning. Selecting the appropriate technique depends on material thickness, end-use, and desired user experience to optimize functionality and aesthetics.

Perforation vs scoring Infographic

libmatt.com

libmatt.com