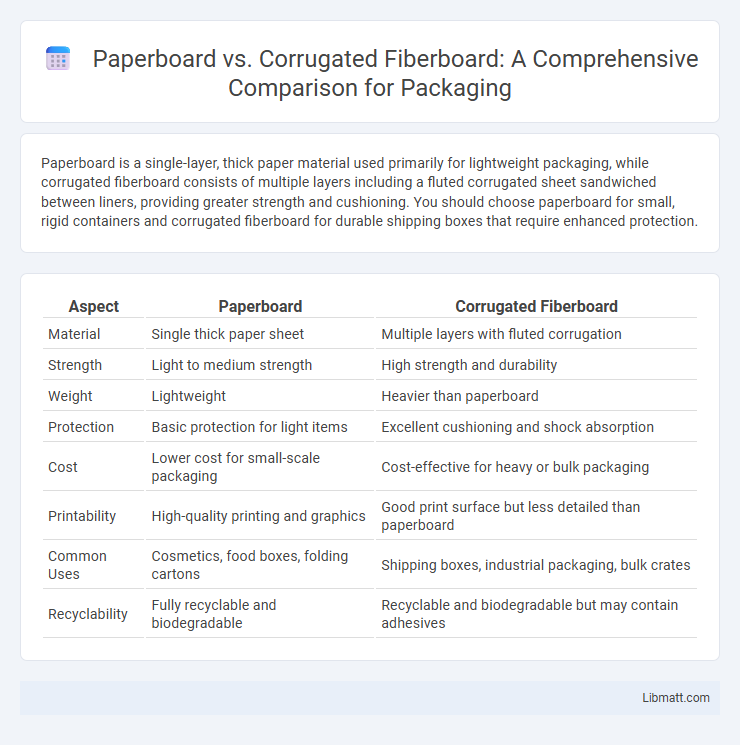

Paperboard is a single-layer, thick paper material used primarily for lightweight packaging, while corrugated fiberboard consists of multiple layers including a fluted corrugated sheet sandwiched between liners, providing greater strength and cushioning. You should choose paperboard for small, rigid containers and corrugated fiberboard for durable shipping boxes that require enhanced protection.

Table of Comparison

| Aspect | Paperboard | Corrugated Fiberboard |

|---|---|---|

| Material | Single thick paper sheet | Multiple layers with fluted corrugation |

| Strength | Light to medium strength | High strength and durability |

| Weight | Lightweight | Heavier than paperboard |

| Protection | Basic protection for light items | Excellent cushioning and shock absorption |

| Cost | Lower cost for small-scale packaging | Cost-effective for heavy or bulk packaging |

| Printability | High-quality printing and graphics | Good print surface but less detailed than paperboard |

| Common Uses | Cosmetics, food boxes, folding cartons | Shipping boxes, industrial packaging, bulk crates |

| Recyclability | Fully recyclable and biodegradable | Recyclable and biodegradable but may contain adhesives |

Introduction to Paperboard and Corrugated Fiberboard

Paperboard is a thick, paper-based material primarily used for packaging lightweight products like food and cosmetics, characterized by its smooth surface and stiffness. Corrugated fiberboard consists of a fluted corrugated sheet sandwiched between flat linerboards, providing enhanced strength and cushioning ideal for shipping and heavy-duty packaging. Your choice between paperboard and corrugated fiberboard depends on the required durability, protection level, and intended use of the packaging.

Defining Paperboard: Features and Characteristics

Paperboard is a thick, sturdy paper-based material characterized by its smooth surface, uniform thickness, and high rigidity, making it ideal for packaging applications requiring a lightweight yet durable solution. Unlike corrugated fiberboard, which includes a fluted corrugated layer sandwiched between liners for enhanced cushioning and structural strength, paperboard offers excellent printability and is often used for folding cartons, trays, and printing applications. Your choice between the two depends on factors like weight requirements, protective needs, and printing quality.

What is Corrugated Fiberboard? Structure and Composition

Corrugated fiberboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength and cushioning properties compared to solid paperboard. This layered structure is typically made from kraft paper or recycled fibers, optimizing durability and lightweight characteristics for packaging applications. The unique corrugated design increases rigidity and resistance to crushing, making it ideal for shipping containers and protective packaging solutions.

Key Differences Between Paperboard and Corrugated Fiberboard

Paperboard is a solid, thick paper material typically used for packaging lighter items, characterized by its smooth surface and rigid structure, while corrugated fiberboard consists of a fluted corrugated sheet sandwiched between two linerboards, providing enhanced strength and cushioning for heavier or fragile goods. Paperboard is commonly used for folding cartons, cereal boxes, and other single-layer packaging, whereas corrugated fiberboard is preferred for shipping containers and protective packaging due to its superior durability and impact resistance. The key differences lie in their composition, strength, weight capacity, and typical applications within the packaging industry.

Common Uses of Paperboard in Packaging

Paperboard is commonly used for packaging lightweight consumer goods such as cereal boxes, cosmetics, pharmaceuticals, and food containers due to its smooth surface and excellent printability. It provides sufficient rigidity for retail packaging while being cost-effective and easy to customize with various coatings and finishes. Unlike corrugated fiberboard, which is preferred for shipping and heavy-duty protection, paperboard excels in applications requiring a premium appearance and precise graphics.

Applications of Corrugated Fiberboard Across Industries

Corrugated fiberboard is extensively used in shipping and packaging industries due to its superior strength, cushioning properties, and lightweight nature, making it ideal for protecting fragile and heavy items during transit. The food and beverage sector relies on corrugated fiberboard for transporting perishable goods, where moisture resistance and ventilation features are critical. Additionally, the electronics and automotive industries utilize corrugated fiberboard for custom packaging solutions that prevent damage and ensure efficient handling.

Strength, Durability, and Protective Qualities Compared

Paperboard offers lightweight strength suitable for packaging small, lightweight items but lacks the structural rigidity of corrugated fiberboard. Corrugated fiberboard features layered construction with fluted inner sheets, providing superior durability, enhanced cushioning, and excellent impact resistance. Your choice depends on the need for protection during transit, with corrugated fiberboard ideal for heavy-duty shipping and paperboard best for lightweight, retail packaging.

Sustainability and Environmental Impact Analysis

Paperboard and corrugated fiberboard both offer sustainable packaging solutions, with paperboard typically requiring less raw material and energy to produce due to its thinner structure. Corrugated fiberboard excels in recyclability and biodegradability, benefiting from a higher content of recycled fibers and greater durability that reduces the need for multiple packaging layers. Lifecycle assessments reveal that corrugated fiberboard often has a lower carbon footprint, primarily owing to its efficient resource use and superior performance in protecting goods, which minimizes waste and transportation emissions.

Cost Considerations: Paperboard vs Corrugated Fiberboard

Paperboard generally offers a lower upfront cost due to its thin, lightweight structure, making it ideal for packaging lightweight products. Corrugated fiberboard, while more expensive initially, provides greater durability and protection, reducing potential damage and replacement costs for heavier or fragile items. Choosing the right material depends on balancing the upfront cost with the potential savings from enhanced product protection and shipping efficiency.

Choosing the Right Material: Factors to Consider

When choosing between paperboard and corrugated fiberboard, consider factors such as durability, weight capacity, and cost-effectiveness. Paperboard offers a smooth surface ideal for high-quality printing and lightweight packaging, while corrugated fiberboard provides superior strength and cushioning for heavier items. Evaluate the product's fragility, shipping conditions, and budget constraints to select the optimal packaging material.

Paperboard vs corrugated fiberboard Infographic

libmatt.com

libmatt.com