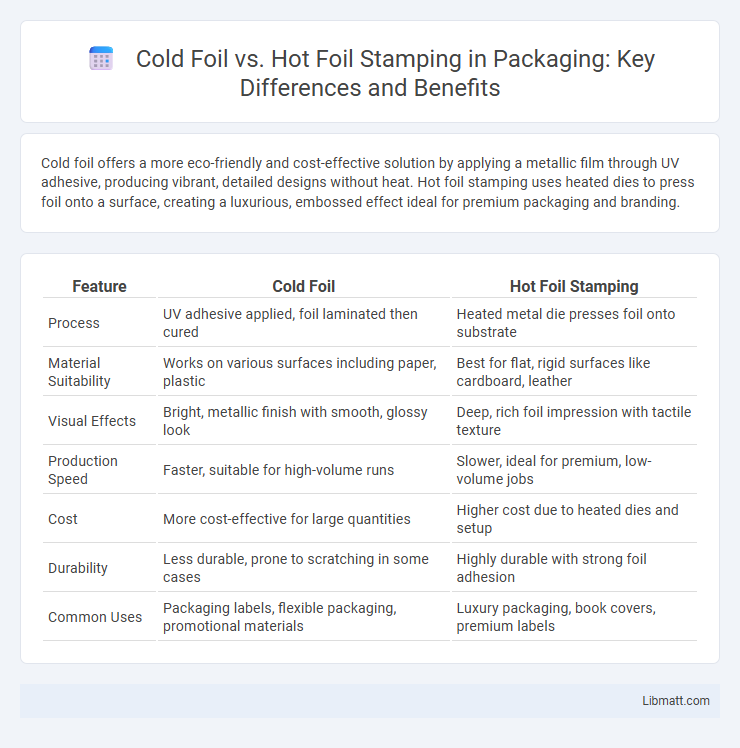

Cold foil offers a more eco-friendly and cost-effective solution by applying a metallic film through UV adhesive, producing vibrant, detailed designs without heat. Hot foil stamping uses heated dies to press foil onto a surface, creating a luxurious, embossed effect ideal for premium packaging and branding.

Table of Comparison

| Feature | Cold Foil | Hot Foil Stamping |

|---|---|---|

| Process | UV adhesive applied, foil laminated then cured | Heated metal die presses foil onto substrate |

| Material Suitability | Works on various surfaces including paper, plastic | Best for flat, rigid surfaces like cardboard, leather |

| Visual Effects | Bright, metallic finish with smooth, glossy look | Deep, rich foil impression with tactile texture |

| Production Speed | Faster, suitable for high-volume runs | Slower, ideal for premium, low-volume jobs |

| Cost | More cost-effective for large quantities | Higher cost due to heated dies and setup |

| Durability | Less durable, prone to scratching in some cases | Highly durable with strong foil adhesion |

| Common Uses | Packaging labels, flexible packaging, promotional materials | Luxury packaging, book covers, premium labels |

Introduction to Foil Stamping Techniques

Cold foil stamping uses a UV-cured adhesive and foil transfer without heat, resulting in precise metallic finishes on paper and synthetic substrates. Hot foil stamping applies heat, pressure, and metal foil with a heated die, creating durable, embossed designs ideal for luxury packaging and branding. Your choice depends on the desired texture, cost-effectiveness, and substrate compatibility for achieving premium visual effects.

What is Cold Foil Stamping?

Cold foil stamping is a printing technique that applies metallic foil to a surface using a UV adhesive and a laminating process without heat. This method is faster and more cost-effective than hot foil stamping, allowing for vibrant metallic effects on paper, cardboard, and other substrates. You can achieve high-detail designs and intricate patterns with cold foil stamping, ideal for packaging and promotional materials.

What is Hot Foil Stamping?

Hot foil stamping is a printing technique that uses heat, pressure, and metallic or pigmented foil to create vibrant, durable designs on various surfaces like paper, leather, and plastics. This process involves a heated metal die pressing the foil onto the substrate, resulting in a shiny, embossed effect with high visual appeal. Hot foil stamping is widely used in luxury packaging, greeting cards, and book covers to add premium, eye-catching details.

Key Differences Between Cold Foil and Hot Foil Stamping

Cold foil uses a UV adhesive and metallic foil applied at high speed without heat, ideal for intricate designs and fast production runs. Hot foil stamping relies on heat and pressure to transfer foil onto surfaces, offering deeper foil impressions and durability suited for premium packaging. Your choice between cold foil and hot foil stamping depends on the desired finish, production speed, and material compatibility.

Advantages of Cold Foil Stamping

Cold foil stamping offers distinct advantages such as faster production times and lower energy consumption compared to hot foil stamping. Its ability to apply foil to heat-sensitive substrates without warping or discoloration makes it ideal for a wide range of materials. Moreover, cold foil stamping provides vibrant metallic finishes with excellent adhesion, enhancing product appearance and durability.

Benefits of Hot Foil Stamping

Hot foil stamping offers superior durability and a high-quality, luxurious finish that enhances brand perception on packaging and printed materials. This method allows for precise, vibrant metallic effects with excellent resistance to abrasion, making it ideal for premium products. Your designs benefit from consistent embossing and sharp detail, ensuring a lasting impression that stands out on various surfaces.

Application Areas: Cold Foil vs. Hot Foil

Cold foil is commonly used for high-volume packaging, labels, and flexible materials, offering quick application and vibrant metallic effects. Hot foil stamping excels in premium packaging, luxury invitations, and book covers, providing deep embossing and rich foil adhesion. Your choice depends on the desired finish, substrate, and production speed for optimal application results.

Design and Material Compatibility

Cold foil offers greater flexibility in design, allowing intricate patterns and fine details to be applied on a wide range of materials, including coated papers and synthetics. Hot foil stamping requires higher temperatures, limiting its use to heat-tolerant substrates like specific leathers and thick cardstock, but it delivers a more pronounced, embossed effect. Understanding your design complexity and material type ensures you select the best foiling method to achieve vibrant and durable finishes.

Cost Comparison: Cold Foil vs. Hot Foil

Cold foil printing generally offers a lower cost per unit compared to hot foil stamping, especially for large print runs due to its faster production time and less complex machinery. Hot foil stamping incurs higher costs from the need for custom metal dies and slower press setup, making it more expensive for small to medium volumes. Budget-conscious projects benefit from cold foil's efficiency, while premium applications may justify hot foil's higher price with its deeper embossing and richer metallic effects.

Choosing the Right Foil Stamping Method for Your Project

Cold foil stamping offers high-speed production and vibrant metallic finishes ideal for large runs and intricate designs, while hot foil stamping provides deep embossing and durability suited for premium packaging and luxury branding. Evaluate project requirements such as budget, material compatibility, desired texture, and production volume to determine the optimal technique. Selecting the right foil stamping method enhances visual impact, print quality, and overall brand presentation.

Cold foil vs hot foil stamping Infographic

libmatt.com

libmatt.com