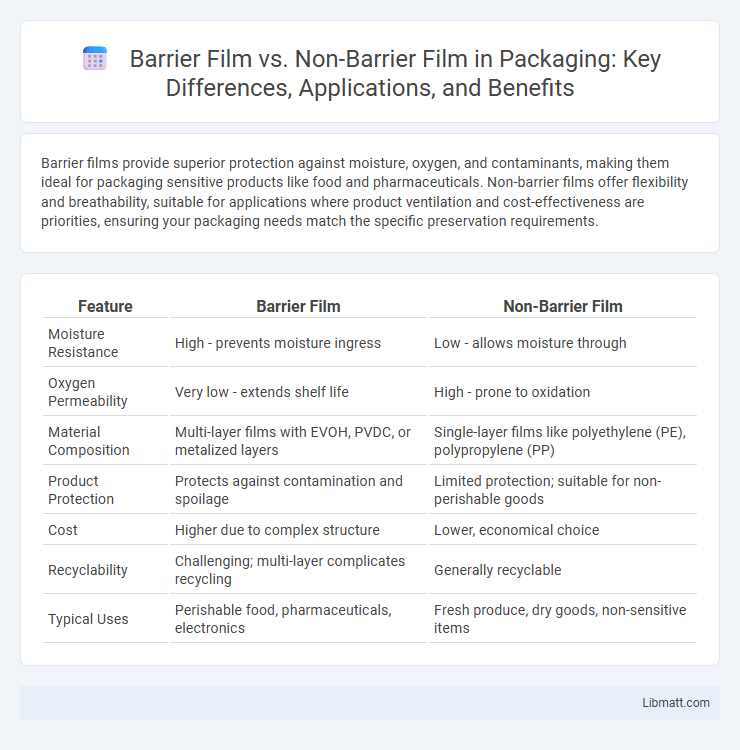

Barrier films provide superior protection against moisture, oxygen, and contaminants, making them ideal for packaging sensitive products like food and pharmaceuticals. Non-barrier films offer flexibility and breathability, suitable for applications where product ventilation and cost-effectiveness are priorities, ensuring your packaging needs match the specific preservation requirements.

Table of Comparison

| Feature | Barrier Film | Non-Barrier Film |

|---|---|---|

| Moisture Resistance | High - prevents moisture ingress | Low - allows moisture through |

| Oxygen Permeability | Very low - extends shelf life | High - prone to oxidation |

| Material Composition | Multi-layer films with EVOH, PVDC, or metalized layers | Single-layer films like polyethylene (PE), polypropylene (PP) |

| Product Protection | Protects against contamination and spoilage | Limited protection; suitable for non-perishable goods |

| Cost | Higher due to complex structure | Lower, economical choice |

| Recyclability | Challenging; multi-layer complicates recycling | Generally recyclable |

| Typical Uses | Perishable food, pharmaceuticals, electronics | Fresh produce, dry goods, non-sensitive items |

Introduction to Barrier and Non-Barrier Films

Barrier films are specialized packaging materials designed to provide superior protection against moisture, oxygen, and other environmental factors, enhancing product shelf life and maintaining quality. Non-barrier films, in contrast, offer limited or no protection against gas and moisture permeation, making them suitable for applications where extended preservation is not critical. The selection between barrier and non-barrier films depends on specific product requirements, environmental exposure, and desired shelf life.

What is a Barrier Film?

A barrier film is a specialized packaging material designed to prevent the passage of gases, moisture, and contaminants, thereby extending the shelf life and preserving the quality of products. These films are commonly used in food, pharmaceuticals, and electronics to protect sensitive contents from environmental factors like oxygen and humidity. Your choice between barrier film and non-barrier film depends on the need for product protection and durability during storage and transportation.

Understanding Non-Barrier Films

Non-barrier films are flexible packaging materials designed to provide basic protection without preventing the passage of moisture, gases, or aromas, making them suitable for items with low moisture sensitivity. These films typically include polyethylene (PE) and polypropylene (PP), which offer excellent moisture resistance but limited oxygen or odor control. Understanding non-barrier films is crucial in selecting packaging that balances cost-effectiveness with the specific preservation needs of the product, especially when extended shelf life is not a primary concern.

Key Differences Between Barrier and Non-Barrier Films

Barrier films provide superior protection against moisture, oxygen, and contaminants, making them ideal for sensitive products like food, pharmaceuticals, and electronics. Non-barrier films, while more cost-effective and flexible, offer minimal resistance to external elements, often used for short-term packaging or where protection is less critical. Understanding your product's preservation needs helps determine if barrier technology is necessary for optimal performance.

Applications of Barrier Films

Barrier films are essential in packaging to protect food, pharmaceuticals, and electronics by preventing moisture, oxygen, and contaminants from penetrating. These films are widely used in vacuum packaging, medical device sterilization, and flexible electronics encapsulation, where maintaining product integrity and extending shelf life are critical. Your choice of barrier film can directly impact product safety and durability in specialized applications requiring high-performance protection.

Common Uses of Non-Barrier Films

Non-barrier films are commonly used in applications such as produce bags, garbage liners, and general-purpose packaging where breathability and flexibility are essential. These films allow moisture and air transmission, making them suitable for short-term storage and items that do not require protection from oxygen, moisture, or contaminants. Non-barrier films are favored in packaging fresh fruits, vegetables, and bakery products, maintaining product freshness without the need for moisture resistance.

Advantages of Barrier Films

Barrier films provide superior protection against moisture, oxygen, and contaminants, significantly extending the shelf life of perishable products. These films help maintain product freshness and quality by preventing spoilage and preserving flavor, color, and texture. Your packaging solutions benefit from reduced waste and enhanced durability when using barrier films compared to non-barrier alternatives.

Benefits of Using Non-Barrier Films

Non-barrier films offer superior breathability, making them ideal for applications requiring moisture and gas permeability, such as fresh produce packaging and medical dressings. These films promote freshness by allowing oxygen exchange, which helps prevent condensation and microbial growth. Their cost-effectiveness and lightweight nature also contribute to reduced material use and easier disposal, enhancing sustainability.

How to Choose Between Barrier and Non-Barrier Films

Choosing between barrier and non-barrier films depends on the specific protection needs of your product. Barrier films provide superior resistance to moisture, oxygen, and contaminants, making them ideal for perishable food packaging and pharmaceuticals. Non-barrier films are suitable for applications requiring flexibility and breathability, such as produce bags or cases where prolonged shelf life is not critical to your product's safety or quality.

Future Trends in Barrier and Non-Barrier Film Technology

Emerging trends in barrier film technology emphasize enhanced oxygen and moisture resistance through nanocomposite coatings and bio-based polymers, driving sustainability and improved food preservation. Non-barrier films leverage advancements in biodegradable materials and cost-effective manufacturing techniques, expanding their application in short-term packaging solutions. Integration of smart sensors and printable electronics in both barrier and non-barrier films is expected to revolutionize interactive packaging and supply chain transparency.

Barrier film vs non-barrier film Infographic

libmatt.com

libmatt.com