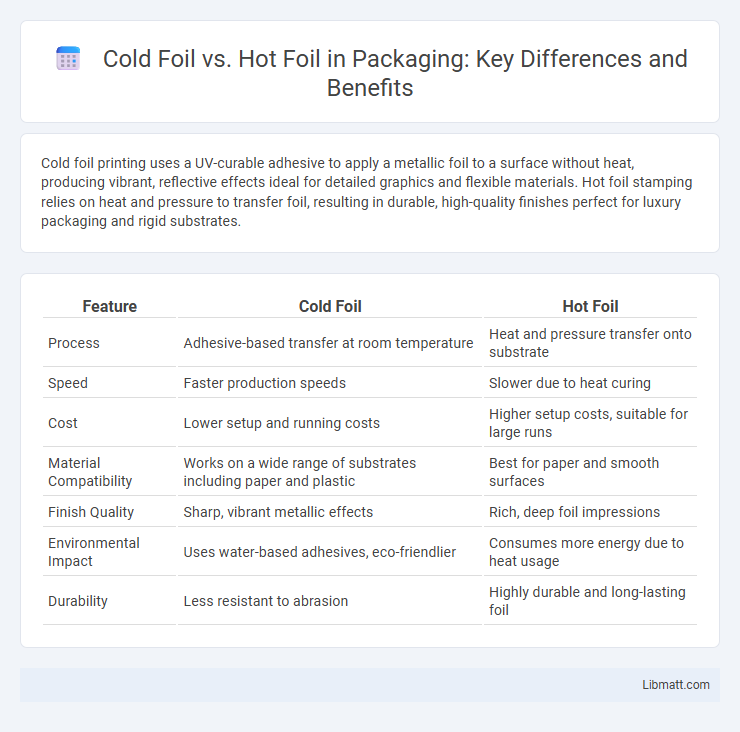

Cold foil printing uses a UV-curable adhesive to apply a metallic foil to a surface without heat, producing vibrant, reflective effects ideal for detailed graphics and flexible materials. Hot foil stamping relies on heat and pressure to transfer foil, resulting in durable, high-quality finishes perfect for luxury packaging and rigid substrates.

Table of Comparison

| Feature | Cold Foil | Hot Foil |

|---|---|---|

| Process | Adhesive-based transfer at room temperature | Heat and pressure transfer onto substrate |

| Speed | Faster production speeds | Slower due to heat curing |

| Cost | Lower setup and running costs | Higher setup costs, suitable for large runs |

| Material Compatibility | Works on a wide range of substrates including paper and plastic | Best for paper and smooth surfaces |

| Finish Quality | Sharp, vibrant metallic effects | Rich, deep foil impressions |

| Environmental Impact | Uses water-based adhesives, eco-friendlier | Consumes more energy due to heat usage |

| Durability | Less resistant to abrasion | Highly durable and long-lasting foil |

Introduction to Foil Stamping Techniques

Foil stamping techniques enhance product packaging and printed materials with metallic or pigmented foil layers. Cold foil uses UV-curable adhesives and digital printing methods to apply foil, offering faster turnaround and lower setup costs, while hot foil employs heat and pressure with metal dies for a traditional, high-quality finish. Understanding these methods allows you to choose the right foil stamping technique based on project complexity, budget, and desired visual impact.

Understanding Cold Foil Stamping

Cold foil stamping uses a UV-cured adhesive and thin metal foil transferred onto the substrate with heat and pressure, delivering vibrant metallic finishes without high temperatures. This method provides superior detail and versatility on various materials, including soft plastics and delicate paper stocks, compared to hot foil stamping, which relies on heated dies to embed foil. Understanding cold foil stamping helps you choose the best technique for achieving high-quality, eco-friendly metallic effects in your packaging or print projects.

Overview of Hot Foil Stamping

Hot foil stamping uses heat and pressure to transfer metallic or pigmented foil onto a surface, creating vibrant, durable designs ideal for packaging, labels, and stationery. This process relies on a heated metal die that activates the adhesive on the foil, ensuring precise and high-quality impressions with a glossy or matte finish. Compared to cold foil, hot foil stamping offers superior adhesion and a more tactile, embossed effect that enhances brand aesthetics and perceived value.

Key Differences Between Cold Foil and Hot Foil

Cold foil uses ultraviolet (UV) adhesive and metallic foil applied through a printing process, resulting in thinner, more flexible designs ideal for complex graphics and fast production. Hot foil employs heat and pressure to transfer metallic foil onto a substrate, producing thicker, more durable finishes suited for premium packaging and luxury branding. Cold foil offers cost efficiency and faster setup, whereas hot foil provides superior texture and longevity.

Material Compatibility: Cold vs. Hot Foil

Cold foil printing works best on smooth, coated papers and certain synthetics, offering superior adhesion on delicate or heat-sensitive materials without warping. Hot foil stamping requires heat and pressure, making it ideal for thicker, more durable substrates like cardstock, leather, and plastics that can withstand high temperatures. Your choice between cold and hot foil should consider the material's heat tolerance and surface texture to ensure optimal foil bonding and longevity.

Design Capabilities and Effects

Cold foil printing enables intricate design capabilities with a wider color palette and finer details, producing vibrant metallic effects through adhesive application and foil transfer at room temperature. Hot foil stamping uses heat and pressure to emboss foil onto surfaces, resulting in a distinguished texture and a more reflective, durable finish ideal for luxury packaging and invitations. Your choice between cold foil and hot foil impacts the visual appeal and tactile experience, balancing design complexity with the desired metallic effect quality.

Production Speed and Efficiency

Cold foil stamping offers faster production speeds due to its simpler application process and immediate curing, making it ideal for high-volume runs with quick turnarounds. Hot foil stamping requires longer setup times and heat activation, which can slow down production but delivers high-quality, durable finishes suitable for premium packaging. Efficiency in cold foil is enhanced by lower energy consumption and less material waste compared to the heat-intensive and often more resource-demanding hot foil process.

Cost Comparison: Cold Foil vs. Hot Foil

Cold foil technology generally offers lower upfront costs compared to hot foil stamping, making it more cost-effective for short to medium print runs. Hot foil requires specialized equipment and higher energy consumption, leading to increased operational expenses that are justified mostly in large-volume projects. Your choice depends on budget constraints and production volume, with cold foil providing a more economical option for smaller batches.

Environmental Impact and Sustainability

Cold foil uses UV-cured adhesives and aluminum foil, generating less energy consumption and fewer VOC emissions compared to hot foil, which relies on heat and pressure with metallic foils that can produce more waste and higher carbon footprints. Cold foil processes enable easier recycling of substrates due to the adhesive's properties, while hot foil stamping can complicate recycling by embedding foil more deeply into the material. Sustainable printing practices increasingly favor cold foil for its lower environmental impact and enhanced recyclability, supporting eco-friendly packaging and promotional materials.

Choosing the Right Foil Stamping Method

Cold foil stamping uses a metallic foil transferred via adhesive and UV curing, offering vibrant colors and detailed designs ideal for packaging and labels, while hot foil stamping applies heat and pressure to bond foil onto surfaces for a durable, classic metallic finish. Your choice depends on factors like desired visual effects, substrate compatibility, production speed, and budget constraints. Cold foil suits high-volume runs with intricate graphics, whereas hot foil excels in premium, tactile applications requiring greater durability.

Cold foil vs hot foil Infographic

libmatt.com

libmatt.com