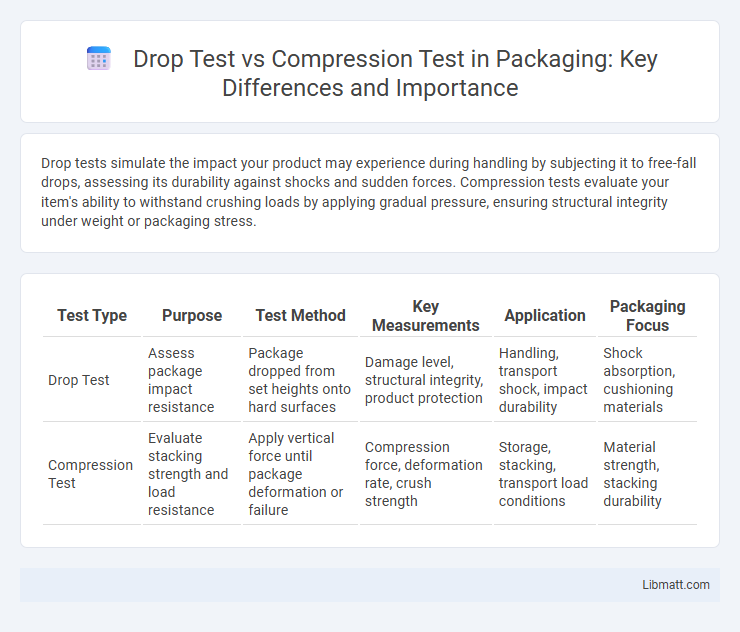

Drop tests simulate the impact your product may experience during handling by subjecting it to free-fall drops, assessing its durability against shocks and sudden forces. Compression tests evaluate your item's ability to withstand crushing loads by applying gradual pressure, ensuring structural integrity under weight or packaging stress.

Table of Comparison

| Test Type | Purpose | Test Method | Key Measurements | Application | Packaging Focus |

|---|---|---|---|---|---|

| Drop Test | Assess package impact resistance | Package dropped from set heights onto hard surfaces | Damage level, structural integrity, product protection | Handling, transport shock, impact durability | Shock absorption, cushioning materials |

| Compression Test | Evaluate stacking strength and load resistance | Apply vertical force until package deformation or failure | Compression force, deformation rate, crush strength | Storage, stacking, transport load conditions | Material strength, stacking durability |

Introduction to Drop Test and Compression Test

Drop tests evaluate a product's durability by simulating impact forces when dropped from various heights, measuring resistance to sudden shocks. Compression tests assess materials or products under gradually increasing loads to determine their strength, deformation limits, and load-bearing capacity. Both tests are critical in quality control and product design for ensuring safety and performance under real-world conditions.

Key Differences Between Drop Test and Compression Test

Drop tests evaluate product durability by simulating impacts and shocks during handling, focusing on resistance to sudden forces and potential breakage. Compression tests measure a material's or package's ability to withstand static loads and pressure to assess structural integrity under continuous force. The key differences lie in the type of stress applied: dynamic impact for drop tests versus static load for compression tests.

Purpose and Objectives of Each Test

Drop tests evaluate a product's ability to withstand impact and shock by simulating real-world falls, aiming to identify damage points and improve packaging durability. Compression tests measure the force a product or packaging can endure under sustained pressure, ensuring structural integrity and preventing deformation during stacking or storage. Both tests target different stress factors to enhance product protection and reliability in transportation and handling.

Drop Test: Procedures and Standards

Drop test procedures typically involve dropping a product from a specified height onto a designated surface to assess its durability and impact resistance, following standards such as ASTM D5276 or ISO 2248. These tests measure how well packaging or devices perform under sudden shock conditions, with parameters including drop height, orientation, and number of drops precisely defined to simulate real-world handling scenarios. Your product's compliance with established drop test standards ensures reliable performance and protection during transportation and distribution.

Compression Test: Procedures and Standards

Compression tests follow standardized procedures such as ASTM D695 and ISO 604, which specify sample preparation, machine calibration, and testing speed. Specimens are typically cylindrical or prismatic, subjected to controlled compressive loads until failure or deformation occurs, allowing measurement of compressive strength, modulus, and yield point. Precise alignment and consistent test conditions ensure reliable, repeatable data critical for material selection and quality control in engineering applications.

Equipment Used in Drop and Compression Testing

Drop testing equipment typically includes impact hoppers, drop towers, and instrumented sensors to measure forces and shock absorption, designed to simulate real-world falls and impacts. Compression testing utilizes universal testing machines equipped with compression platens and load cells to apply controlled pressure and record material or product deformation and strength. Both types of equipment are crucial for assessing product durability and packaging integrity under different stress conditions.

Applications in Packaging and Product Design

Drop tests simulate impacts to evaluate packaging durability and product protection during shipping, identifying weak points that may cause damage. Compression tests measure the material strength and stacking capability of packaging, ensuring stability under load during storage and transportation. Both tests optimize packaging design by enhancing material selection and structural integrity to prevent product failure.

Interpreting Results: What Do They Indicate?

Drop test results indicate product durability and impact resistance by showing how well an item withstands sudden shocks or falls, revealing potential weaknesses in design or materials. Compression test outcomes measure a product's ability to resist crushing forces, indicating structural integrity and load-bearing capacity under pressure. Interpreting both tests together provides a comprehensive understanding of a product's performance under different stress conditions, essential for quality control and safety assurance.

Industry-Specific Test Requirements

Drop tests evaluate product durability by simulating impacts during handling and transport, essential for industries like electronics and packaging where shipment damage is common. Compression tests measure a material or packaging's ability to withstand crushing forces, critical in sectors such as construction and logistics where stacking strength ensures product integrity. Your choice between these tests depends on the specific stresses your product will face during its lifecycle and regulatory standards within your industry.

Choosing the Right Test for Your Product

Choosing the right test for your product depends on its intended use and the type of mechanical stress it will encounter. Drop tests evaluate a product's ability to withstand impact and shock from falls, making them essential for fragile electronics and transportation packaging. Compression tests measure resistance to crushing forces, crucial for structural materials and products stored in stacked conditions.

Drop test vs compression test Infographic

libmatt.com

libmatt.com