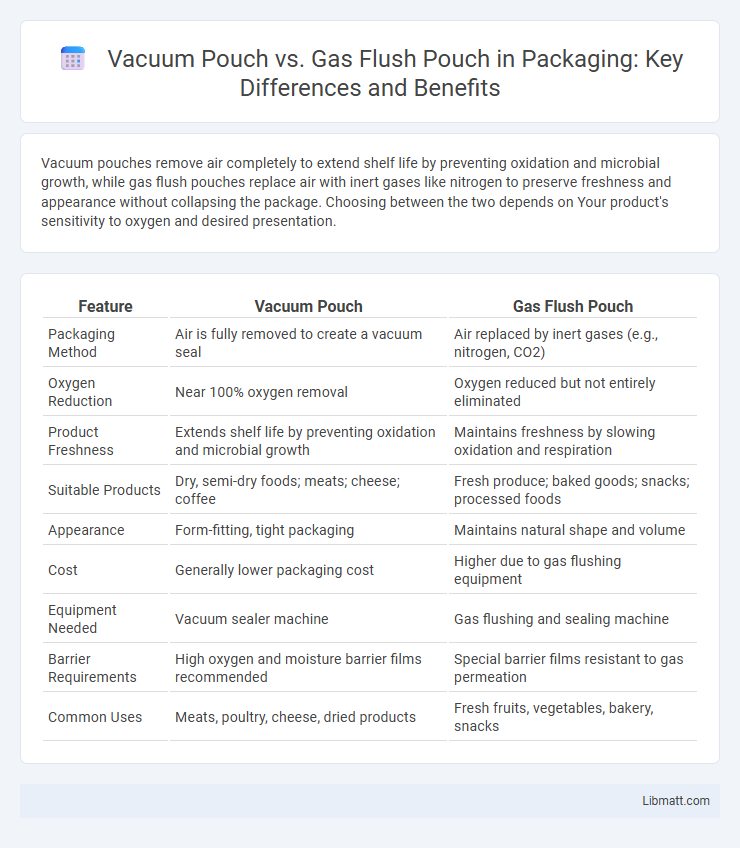

Vacuum pouches remove air completely to extend shelf life by preventing oxidation and microbial growth, while gas flush pouches replace air with inert gases like nitrogen to preserve freshness and appearance without collapsing the package. Choosing between the two depends on Your product's sensitivity to oxygen and desired presentation.

Table of Comparison

| Feature | Vacuum Pouch | Gas Flush Pouch |

|---|---|---|

| Packaging Method | Air is fully removed to create a vacuum seal | Air replaced by inert gases (e.g., nitrogen, CO2) |

| Oxygen Reduction | Near 100% oxygen removal | Oxygen reduced but not entirely eliminated |

| Product Freshness | Extends shelf life by preventing oxidation and microbial growth | Maintains freshness by slowing oxidation and respiration |

| Suitable Products | Dry, semi-dry foods; meats; cheese; coffee | Fresh produce; baked goods; snacks; processed foods |

| Appearance | Form-fitting, tight packaging | Maintains natural shape and volume |

| Cost | Generally lower packaging cost | Higher due to gas flushing equipment |

| Equipment Needed | Vacuum sealer machine | Gas flushing and sealing machine |

| Barrier Requirements | High oxygen and moisture barrier films recommended | Special barrier films resistant to gas permeation |

| Common Uses | Meats, poultry, cheese, dried products | Fresh fruits, vegetables, bakery, snacks |

Introduction to Vacuum Pouch and Gas Flush Pouch

Vacuum pouches remove air from packaging to extend product shelf life by inhibiting oxidation and microbial growth, commonly used for meats, cheeses, and perishable goods. Gas flush pouches replace oxygen with inert gases like nitrogen or carbon dioxide, preserving freshness and texture while preventing spoilage in products such as fresh produce and baked goods. Both packaging methods enhance product longevity but utilize different atmospheric modifications to maintain quality.

What is a Vacuum Pouch?

A vacuum pouch is a specially designed packaging bag that removes air to create a tight seal, preserving the freshness and shelf life of food products by minimizing oxidation and microbial growth. These pouches are typically made from multilayer films that provide barrier properties against moisture, oxygen, and contaminants. Your choice of packaging can significantly impact product quality, making vacuum pouches ideal for meats, cheeses, and perishable items.

What is a Gas Flush Pouch?

A gas flush pouch is a specialized packaging solution that replaces oxygen inside the pouch with a protective gas mixture, such as nitrogen or carbon dioxide, to extend product shelf life and preserve freshness. Unlike vacuum pouches that remove air by suction, gas flush pouches maintain the product's shape and prevent compression by filling the package with inert gases. This method is widely used in food packaging for products like meat, cheese, and snacks to inhibit bacterial growth and oxidation.

Key Differences between Vacuum and Gas Flush Pouches

Vacuum pouches remove air completely to prevent oxidation and extend shelf life, while gas flush pouches replace oxygen with inert gases like nitrogen or carbon dioxide to maintain product freshness. Vacuum pouches are ideal for solid foods that can withstand compression, whereas gas flush pouches are better suited for delicate items prone to crushing, such as chips or salads. The choice between these packaging methods depends on product sensitivity to oxygen, texture preservation, and desired shelf life.

Packaging Process Comparison

Vacuum pouches remove air by creating a tight seal around the product, which limits oxygen exposure and extends shelf life, whereas gas flush pouches replace the air inside with inert gases such as nitrogen or carbon dioxide to protect product freshness. The packaging process for vacuum sealing involves a straightforward air extraction and sealing step, making it faster and more cost-effective. Gas flushing requires additional equipment for gas injection and precise control, offering enhanced protection for oxygen-sensitive products but with increased complexity in packaging operations.

Benefits of Vacuum Pouch Packaging

Vacuum pouch packaging extends the shelf life of products by removing air, which inhibits bacterial growth and oxidation. This method preserves the freshness, flavor, and nutritional value of food, making it ideal for perishable items. Your products benefit from reduced spoilage and enhanced presentation with vacuum pouches, ensuring longer-lasting quality.

Advantages of Gas Flush Pouch Packaging

Gas flush pouch packaging extends product shelf life by replacing oxygen with inert gases, significantly slowing oxidation and microbial growth compared to vacuum pouches. This method preserves the product's original texture, flavor, and appearance, maintaining freshness without compressing delicate items. Gas flush packaging also reduces packaging damage risk and is suitable for a broader range of food types, including fragile and moisture-sensitive products.

Best Applications for Each Packaging Method

Vacuum pouches are ideal for preserving shelf life and maintaining freshness in products like raw meats, cheeses, and bulk dry goods by removing air to inhibit oxidation and microbial growth. Gas flush pouches, commonly used for fresh produce, deli meats, and bakery items, replace oxygen with inert gases such as nitrogen or carbon dioxide to prevent spoilage while retaining texture and appearance. Selecting between vacuum sealing and gas flushing depends on the product's sensitivity to oxygen, moisture content, and desired shelf stability.

Cost Considerations: Vacuum vs Gas Flush Pouches

Vacuum pouches generally offer a lower initial cost compared to gas flush pouches due to simpler packaging processes and equipment requirements. Gas flush pouches, which use modified atmosphere packaging (MAP), incur higher expenses from specialized gases and advanced machinery, affecting overall production budgets. Your choice between the two should weigh the balance between upfront costs and the potential for extended product shelf life.

Choosing the Right Pouch for Your Product

Vacuum pouches remove air to extend shelf life by preventing oxidation and microbial growth, ideal for dry or solid products like nuts, coffee, and meats. Gas flush pouches replace oxygen with inert gases such as nitrogen or carbon dioxide, preserving the freshness, color, and texture of sensitive products like fresh-cut fruits, cheese, and seafood. Choosing the right pouch depends on your product's sensitivity to oxygen and moisture, ensuring optimal preservation and quality maintenance.

Vacuum pouch vs gas flush pouch Infographic

libmatt.com

libmatt.com