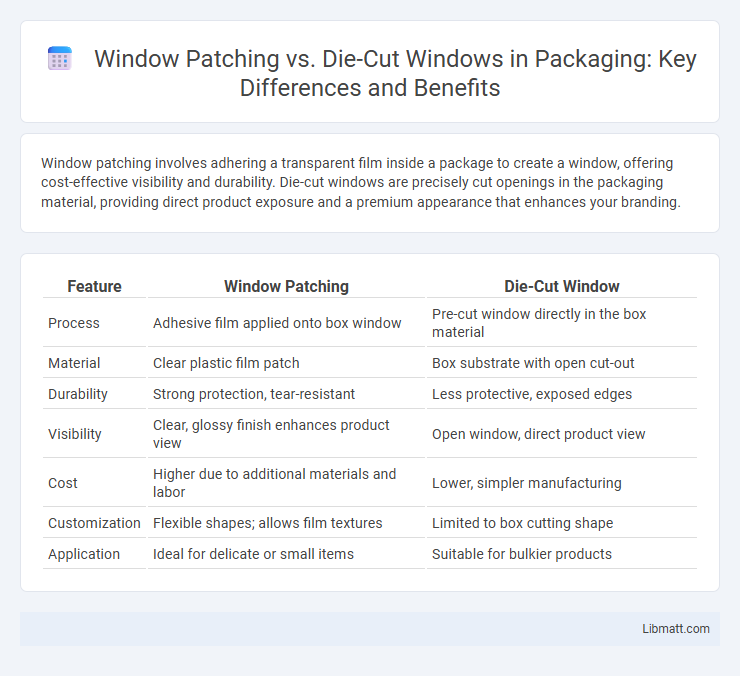

Window patching involves adhering a transparent film inside a package to create a window, offering cost-effective visibility and durability. Die-cut windows are precisely cut openings in the packaging material, providing direct product exposure and a premium appearance that enhances your branding.

Table of Comparison

| Feature | Window Patching | Die-Cut Window |

|---|---|---|

| Process | Adhesive film applied onto box window | Pre-cut window directly in the box material |

| Material | Clear plastic film patch | Box substrate with open cut-out |

| Durability | Strong protection, tear-resistant | Less protective, exposed edges |

| Visibility | Clear, glossy finish enhances product view | Open window, direct product view |

| Cost | Higher due to additional materials and labor | Lower, simpler manufacturing |

| Customization | Flexible shapes; allows film textures | Limited to box cutting shape |

| Application | Ideal for delicate or small items | Suitable for bulkier products |

Introduction to Window Patching and Die-Cut Windows

Window patching involves applying a clear film or plastic patch inside a product's packaging window to enhance durability and protect contents, ensuring visibility without compromising strength. Die-cut windows are precisely cut shapes in packaging materials, created using specialized dies, allowing brands to customize window designs for visual appeal and consumer engagement. Your choice between window patching and die-cut windows depends on balancing durability needs with design flexibility and production costs.

Understanding Window Patching: Definition and Process

Window patching involves applying a transparent film or window material to the inside of a package or envelope window area, creating a smooth surface while maintaining visibility of the contents. This process enhances package strength and durability by reinforcing the window, preventing tearing or damage during handling and shipping. Unlike die-cut windows that are cut directly into the material, window patching seals the window area with an additional layer, improving product presentation and protection.

What is a Die-Cut Window? Key Characteristics

A die-cut window is a precisely shaped opening created in packaging materials such as cardboard or paperboard using a custom die, allowing visibility of the product inside without compromising structural integrity. Key characteristics include clean, uniform edges tailored to various shapes and sizes, offering enhanced appeal and customer interaction with the product. This method provides versatility in design, improving marketing potential while maintaining protection and durability of the packaging.

Materials Used in Window Patching vs Die-Cut Window

Window patching typically uses a thin, clear film made from materials like acetate or cellophane to cover die-cut openings, providing a straightforward and cost-effective solution. Die-cut windows are crafted from plastic films such as PVC, PET, or OPS, precisely cut to specific shapes and sizes to enhance packaging aesthetics and functionality. Your choice between window patching and die-cut windows depends on the desired material durability, transparency, and production method preferences.

Visual Appeal and Design Flexibility Comparison

Window patching offers a subtle, seamless look with a clean finish that enhances the overall visual appeal of packaging, while die-cut windows provide bold, customizable shapes that attract attention and allow creative design possibilities. Die-cut windows give greater flexibility to showcase product features directly, enabling unique brand storytelling through varied shapes and sizes, whereas window patching maintains structural integrity and simplicity. Your choice depends on whether you prioritize sleek elegance or dynamic design expression for packaging visibility.

Durability and Protection: Which Offers More?

Window patching provides enhanced durability and superior protection by applying a clear film that reinforces the window against tears and punctures. Die-cut windows, while offering precise shapes and custom designs, are more susceptible to damage due to their thinner, exposed material. Your choice should prioritize window patching when maximum strength and reliability are essential for packaging integrity.

Cost Factors: Window Patching vs Die-Cut Window

Window patching generally involves lower initial costs due to its simpler production process, making it a budget-friendly option for packaging that requires minimal window size and shape customization. Die-cut window methods, while more expensive because of the need for custom tooling and die creation, offer greater design flexibility and precision, which can enhance product visibility and brand presentation. Your choice between window patching and die-cut windows should consider not only the cost factors but also the desired aesthetic impact and production volume to optimize overall packaging value.

Suitable Applications for Each Technique

Window patching is ideal for applications requiring enhanced durability and a seamless finish, such as luxury packaging or food containers where moisture resistance is critical. Die-cut windows excel in customizable shapes and intricate designs, making them perfect for retail packaging, allowing clear product visibility and branding appeal. Your choice depends on whether you prioritize structural integrity or creative window shapes to showcase the product inside.

Sustainability and Environmental Impact

Window patching involves applying a thin plastic film to a paper envelope, which allows recyclability by separating plastic from paper waste more efficiently, reducing landfill impact. Die-cut windows use transparent plastic films permanently sealed within the envelope, often complicating recycling due to mixed materials that require specialized processing. Choosing window patching over die-cut windows significantly improves sustainability by facilitating easier recycling and minimizing environmental footprint through reduced plastic contamination.

Choosing the Right Option: Factors to Consider

When choosing between window patching and die-cut window options, consider factors such as budget, production volume, and design complexity. Window patching offers a cost-effective solution with flexibility for small runs and intricate shapes, while die-cut windows provide precision and efficiency for larger-scale projects with consistent shapes. Your decision should balance aesthetic needs, durability, and manufacturing timelines to ensure optimal results.

Window patching vs die-cut window Infographic

libmatt.com

libmatt.com