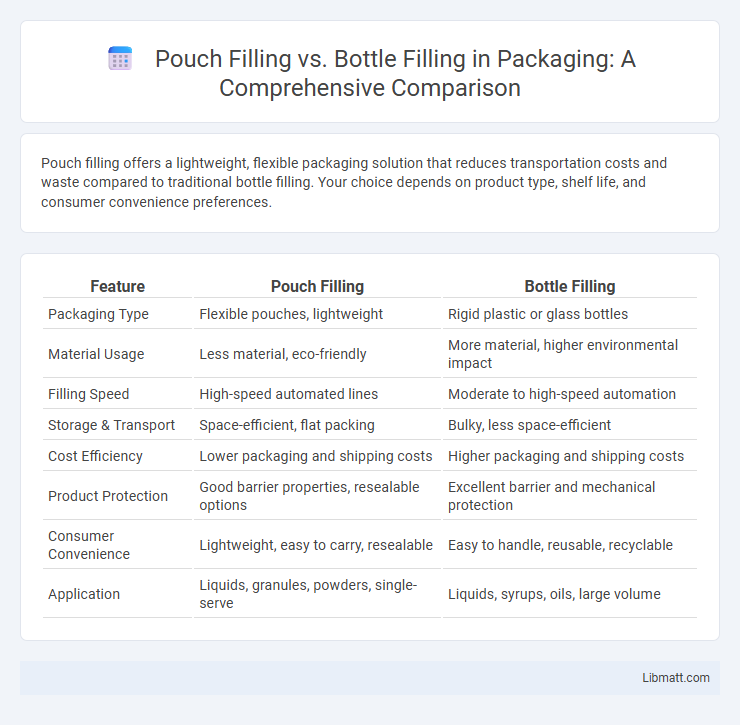

Pouch filling offers a lightweight, flexible packaging solution that reduces transportation costs and waste compared to traditional bottle filling. Your choice depends on product type, shelf life, and consumer convenience preferences.

Table of Comparison

| Feature | Pouch Filling | Bottle Filling |

|---|---|---|

| Packaging Type | Flexible pouches, lightweight | Rigid plastic or glass bottles |

| Material Usage | Less material, eco-friendly | More material, higher environmental impact |

| Filling Speed | High-speed automated lines | Moderate to high-speed automation |

| Storage & Transport | Space-efficient, flat packing | Bulky, less space-efficient |

| Cost Efficiency | Lower packaging and shipping costs | Higher packaging and shipping costs |

| Product Protection | Good barrier properties, resealable options | Excellent barrier and mechanical protection |

| Consumer Convenience | Lightweight, easy to carry, resealable | Easy to handle, reusable, recyclable |

| Application | Liquids, granules, powders, single-serve | Liquids, syrups, oils, large volume |

Introduction to Pouch Filling and Bottle Filling

Pouch filling involves packaging liquids, powders, or solids into flexible bags, offering benefits such as reduced packaging weight and enhanced portability compared to traditional bottle filling. Bottle filling typically uses rigid containers made of glass or plastic, providing superior protection and shelf stability for beverages and liquid products. Both methods require specialized machinery designed for specific product viscosities, filling speeds, and sealing techniques to ensure product integrity and consumer safety.

Overview of the Packaging Processes

Pouch filling involves the direct transfer of product into flexible packaging materials, often incorporating automated sealing to create airtight, lightweight packages ideal for liquids and semi-liquids. Bottle filling uses rigid containers, typically glass or plastic, where the product is dispensed through nozzles into pre-formed bottles that are then capped for protection and preservation. Both processes require precise control of filling volumes and hygiene standards to ensure product safety and shelf life.

Equipment and Technology Used

Pouch filling utilizes advanced form-fill-seal machines that integrate flexible packaging technologies, allowing for high-speed, contamination-free sealing and minimal material waste. Bottle filling employs rotary or linear filling machines equipped with precise volumetric or gravimetric fillers, often combined with capping and labeling units designed for rigid containers. Both systems incorporate sensors and automated controls to ensure accuracy, hygiene, and efficient production tailored to their respective packaging formats.

Material and Packaging Differences

Pouch filling utilizes flexible materials such as laminated films or foil, offering lightweight, space-saving packaging that reduces transportation costs and environmental impact. Bottle filling relies on rigid materials like glass or plastic, providing durability, product protection, and ease of handling but often results in higher material and shipping expenses. The choice between pouch and bottle filling significantly influences packaging sustainability, cost efficiency, and consumer convenience based on material properties.

Cost Comparison: Pouch vs Bottle Filling

Pouch filling typically offers lower packaging and transportation costs compared to bottle filling due to reduced material usage and lighter weight. The flexible nature of pouches minimizes storage space and shipping expenses, enhancing overall cost efficiency. Bottle filling involves higher expenses linked to rigid packaging materials, increased weight, and larger storage requirements, making pouch filling a more economical option for many beverage and liquid product manufacturers.

Environmental Impact and Sustainability

Pouch filling significantly reduces material usage and transportation emissions compared to traditional bottle filling, making it a more sustainable packaging solution. Lightweight, flexible pouches require less plastic and generate less landfill waste, promoting better environmental outcomes. Your choice of pouch filling supports resource conservation and lowers your product's overall carbon footprint.

Product Shelf Life and Preservation

Pouch filling offers superior product shelf life and preservation by minimizing air exposure and allowing for vacuum or modified atmosphere packaging, which reduces oxidation and microbial growth compared to traditional bottle filling. Pouches typically use multi-layer barrier materials that enhance protection against moisture, oxygen, and light, extending freshness without the need for preservatives. Your product maintains optimal quality longer in pouches, making them an excellent choice for preserving sensitive or perishable foods and beverages.

Efficiency and Production Speed

Pouch filling systems typically offer higher efficiency and faster production speeds compared to bottle filling due to their lightweight design and reduced packaging material, enabling quicker sealing and handling processes. Bottle filling often requires more time-consuming steps such as capping and labeling, which can slow down overall production rates. Optimizing your packaging line with pouch filling can significantly boost output while lowering operational costs.

Consumer Preferences and Market Trends

Pouch filling offers convenience, portability, and portion control that align with growing consumer demand for on-the-go lifestyles and eco-friendly packaging, making it a preferred choice in markets focused on sustainability. Bottle filling caters to traditional preferences for resealable and durable packaging, supporting markets where product preservation and premium presentation are critical. Your choice between pouch filling and bottle filling should consider these evolving consumer preferences and market trends to optimize product appeal and competitiveness.

Choosing the Right Filling Method for Your Product

Pouch filling offers advantages such as reduced packaging weight, enhanced portability, and flexible designs ideal for liquid and semi-liquid products, while bottle filling provides superior durability and tamper-evidence, suitable for beverages and high-viscosity liquids. Selecting the right filling method depends on factors including product viscosity, shelf life requirements, target market preferences, and environmental impact goals. Evaluating production speed, cost efficiency, and packaging aesthetics ensures optimal alignment with brand positioning and consumer convenience.

Pouch filling vs bottle filling Infographic

libmatt.com

libmatt.com