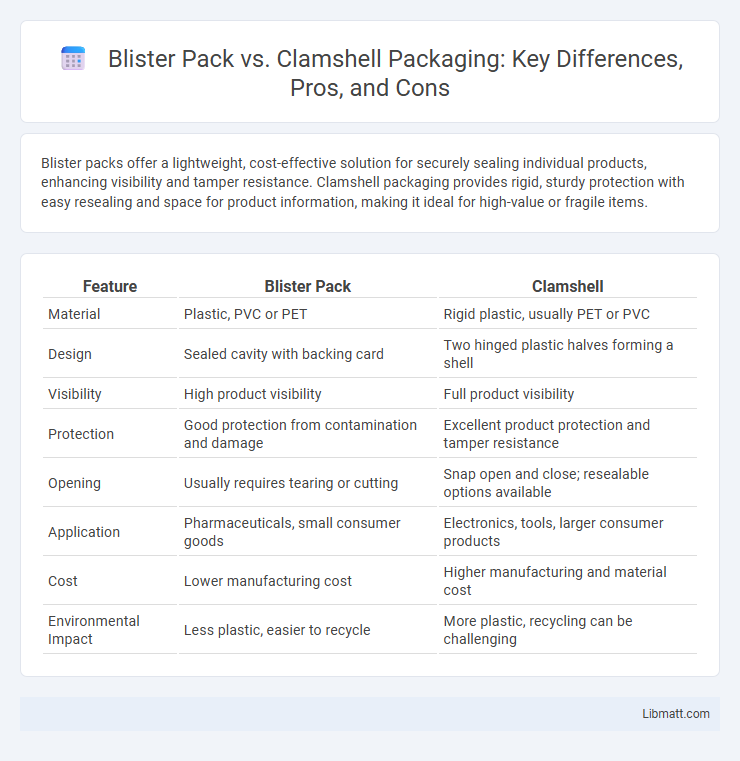

Blister packs offer a lightweight, cost-effective solution for securely sealing individual products, enhancing visibility and tamper resistance. Clamshell packaging provides rigid, sturdy protection with easy resealing and space for product information, making it ideal for high-value or fragile items.

Table of Comparison

| Feature | Blister Pack | Clamshell |

|---|---|---|

| Material | Plastic, PVC or PET | Rigid plastic, usually PET or PVC |

| Design | Sealed cavity with backing card | Two hinged plastic halves forming a shell |

| Visibility | High product visibility | Full product visibility |

| Protection | Good protection from contamination and damage | Excellent product protection and tamper resistance |

| Opening | Usually requires tearing or cutting | Snap open and close; resealable options available |

| Application | Pharmaceuticals, small consumer goods | Electronics, tools, larger consumer products |

| Cost | Lower manufacturing cost | Higher manufacturing and material cost |

| Environmental Impact | Less plastic, easier to recycle | More plastic, recycling can be challenging |

Introduction to Packaging: Blister Packs vs Clamshells

Blister packs consist of a pre-formed plastic cavity sealed to a backing card, providing excellent product visibility and tamper evidence, commonly used for pharmaceuticals and small consumer goods. Clamshell packaging features a hinged, molded plastic case that fully encloses the product, offering superior protection and stackability, often utilized for electronics and hardware items. Both packaging types enhance shelf appeal and product security but differ in materials, functionality, and consumer accessibility.

Defining Blister Packs

Blister packs consist of pre-formed plastic cavities secured with a backing of paperboard or aluminum foil, designed to protect and display individual product units such as pharmaceuticals and small consumer goods. These packs provide tamper-evident packaging, ensuring product integrity while allowing easy access and visibility. Blister packs are favored for their compact design, moisture resistance, and ability to extend shelf life.

Understanding Clamshell Packaging

Clamshell packaging features two hinged plastic halves that securely enclose products, offering superior protection and tamper resistance compared to blister packs. You benefit from enhanced product visibility and easy resealing options, making clamshells ideal for high-value or fragile items. This packaging type reduces product damage and theft, improving shelf appeal and customer confidence in retail environments.

Key Materials Used in Both Packaging Types

Blister packs primarily use PVC (polyvinyl chloride) or PET (polyethylene terephthalate) for the clear plastic cavities, paired with aluminum or paperboard backing to provide structural support and sealing. Clamshell packaging is typically made from thermoformed PET, PVC, or polystyrene, offering rigid, durable protection with hinged or snap closures. Both packaging types emphasize material transparency and durability, but blister packs often prioritize barrier properties while clamshells focus on toughness and reusability.

Protection and Durability Comparison

Blister packs offer excellent protection by securely enclosing individual products in a sealed cavity, minimizing exposure to air and contaminants, which enhances product durability. Clamshell packaging provides robust physical protection due to its hinged, hard plastic design that resists crushing and tampering while allowing easy resealing. Your choice depends on the level of protection needed; blister packs are ideal for smaller, sensitive items, while clamshells are better suited for heavier or bulkier products requiring higher impact resistance.

Consumer Convenience and Accessibility

Blister packs offer easy visibility and single-dose access, enhancing consumer convenience by allowing users to remove one item without disturbing the rest. Clamshell packaging provides robust protection but often requires scissors or tools for opening, which can hinder accessibility for individuals with limited dexterity. Your choice between these packaging types should consider the balance between ease of use and product protection to meet consumer needs effectively.

Cost Efficiency: Blister Packs vs Clamshells

Blister packs generally offer greater cost efficiency due to lower material and manufacturing expenses compared to clamshells, which often require more complex tooling and higher plastic usage. You can reduce packaging costs with blister packs while still maintaining product visibility and protection, making them ideal for mass production. Clamshells, although more durable and secure, typically increase overall packaging costs, impacting budget-sensitive projects.

Environmental Impact and Sustainability

Blister packs often generate more non-recyclable waste due to their combination of plastic and aluminum layers, making them less environmentally friendly compared to clamshell packaging, which can be designed using a single type of recyclable plastic. Your choice of clamshell packaging can support sustainability goals by enabling easier sorting and recycling processes, reducing landfill contributions. Companies increasingly favor clamshells with biodegradable or recycled materials to minimize ecological footprints and comply with environmental regulations.

Industry Applications and Suitability

Blister packs are widely used in the pharmaceutical and consumer goods industries due to their ability to protect products from contamination and provide tamper evidence, making them ideal for medication and small electronics. Clamshell packaging offers superior durability and visibility, making it suitable for retail items like hardware tools, toys, and electronics that require secure packaging and easy product inspection. Your choice between blister pack and clamshell should consider the product's fragility, display needs, and security requirements to ensure optimal protection and consumer appeal.

Choosing the Right Packaging Solution

Choosing the right packaging solution between blister packs and clamshells depends on product protection, visibility, and cost considerations. Blister packs offer rigid, tamper-evident sealing ideal for pharmaceuticals and small electronics, while clamshell packaging provides durable, reusable, and eco-friendly options suitable for larger or irregularly shaped items. Evaluating factors such as product fragility, display appeal, and environmental impact is essential to determine the most effective packaging type.

Blister pack vs clamshell Infographic

libmatt.com

libmatt.com