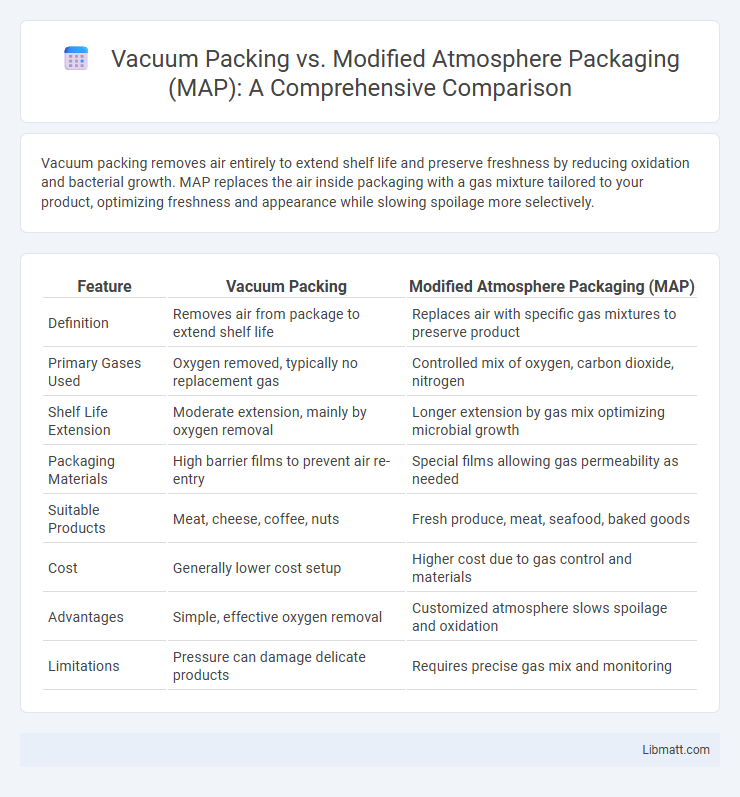

Vacuum packing removes air entirely to extend shelf life and preserve freshness by reducing oxidation and bacterial growth. MAP replaces the air inside packaging with a gas mixture tailored to your product, optimizing freshness and appearance while slowing spoilage more selectively.

Table of Comparison

| Feature | Vacuum Packing | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Removes air from package to extend shelf life | Replaces air with specific gas mixtures to preserve product |

| Primary Gases Used | Oxygen removed, typically no replacement gas | Controlled mix of oxygen, carbon dioxide, nitrogen |

| Shelf Life Extension | Moderate extension, mainly by oxygen removal | Longer extension by gas mix optimizing microbial growth |

| Packaging Materials | High barrier films to prevent air re-entry | Special films allowing gas permeability as needed |

| Suitable Products | Meat, cheese, coffee, nuts | Fresh produce, meat, seafood, baked goods |

| Cost | Generally lower cost setup | Higher cost due to gas control and materials |

| Advantages | Simple, effective oxygen removal | Customized atmosphere slows spoilage and oxidation |

| Limitations | Pressure can damage delicate products | Requires precise gas mix and monitoring |

Introduction to Food Packaging Technologies

Vacuum packing removes air from the packaging to inhibit microbial growth and extend shelf life, making it ideal for perishable foods such as meats and cheeses. Modified Atmosphere Packaging (MAP) replaces the air inside the package with a specific gas mixture, typically oxygen, carbon dioxide, and nitrogen, to slow oxidation and spoilage for fresh produce and baked goods. Both technologies enhance food safety and quality but are tailored to different product types and storage requirements.

What is Vacuum Packing?

Vacuum packing is a preservation method that removes air from the packaging before sealing, significantly reducing oxygen levels to inhibit microbial growth and oxidation. This technique extends shelf life by creating an anaerobic environment that slows spoilage and maintains product freshness, especially for perishable goods like meats and cheeses. Vacuum packing also helps retain flavor and moisture by minimizing exposure to external elements, making it a popular choice in food storage and distribution.

Understanding Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends shelf life by altering the gas composition around food products, typically reducing oxygen and increasing nitrogen or carbon dioxide levels to inhibit microbial growth. Unlike vacuum packing, which removes air entirely, MAP maintains a controlled atmosphere that preserves texture, color, and freshness while reducing spoilage. Understanding MAP helps you select the best packaging method tailored to your product's preservation needs and storage conditions.

Core Differences Between Vacuum Packing and MAP

Vacuum packing removes air entirely from the packaging, creating an oxygen-free environment that slows down oxidation and microbial growth, while Modified Atmosphere Packaging (MAP) replaces the air inside the package with a specific gas mixture tailored to the product, such as nitrogen or carbon dioxide, to extend shelf life. The core difference lies in vacuum packing's complete air removal versus MAP's controlled atmosphere adjustment, which can better preserve texture and color for fresh produce and meats. When selecting packaging, Your choice depends on the product type and desired shelf life, as vacuum packing excels in anaerobic preservation and MAP optimizes gas balance for freshness.

Packaging Process: Vacuum Packing vs MAP

Vacuum packing removes air from the package, creating an oxygen-free environment that extends shelf life by slowing oxidation and microbial growth. MAP replaces the air inside the package with a specific gas mixture, such as nitrogen and carbon dioxide, tailored to the product's preservation requirements. Your choice between vacuum packing and MAP depends on the type of food, desired shelf life, and sensitivity to oxygen exposure.

Preservation and Shelf Life Comparison

Vacuum packing removes air to inhibit aerobic bacterial growth, extending shelf life by slowing oxidation and spoilage, typically preserving freshness for several weeks depending on the product. Modified Atmosphere Packaging (MAP) replaces air with specific gas mixtures, such as nitrogen and carbon dioxide, to tailor preservation conditions and further extend shelf life, often doubling or tripling the duration compared to vacuum packing. Your choice depends on the product type and desired shelf life, as MAP generally offers better control over freshness and color retention in perishable goods.

Impact on Food Quality and Safety

Vacuum packing removes air to inhibit microbial growth and oxidation, effectively extending shelf life and preserving sensory qualities such as texture and flavor in foods like meats and cheeses. Modified Atmosphere Packaging (MAP) replaces air with specific gas mixtures (commonly CO2, N2, and O2) to tailor preservation conditions, which can better maintain freshness and color in perishable products like fruits and vegetables. Your choice between vacuum packing and MAP should consider the type of food, desired shelf life, and safety requirements, as MAP offers more customized atmospheres for targeted spoilage prevention while vacuum packaging excels in oxygen-sensitive items.

Application Areas: Ideal Uses for Each Method

Vacuum packing is ideal for preserving products with high moisture content such as meats, cheese, and fresh produce by removing air to inhibit microbial growth and prolong shelf life. Modified Atmosphere Packaging (MAP) suits fresh-cut fruits, vegetables, and bakery goods by replacing oxygen with gases like nitrogen or carbon dioxide to maintain freshness and visual appeal. Your choice depends on the product's sensitivity to oxygen and the desired shelf life extension.

Cost-Effectiveness and Economic Considerations

Vacuum packing generally offers lower initial equipment costs and simpler operational requirements compared to Modified Atmosphere Packaging (MAP), making it more cost-effective for small to medium-scale producers. However, MAP can extend shelf life more significantly, reducing waste and potentially increasing profits in high-volume or premium product markets. Economic considerations must weigh upfront investment against long-term savings from reduced spoilage and enhanced product appeal.

Choosing the Right Packaging: Factors to Consider

Choosing the right packaging depends on factors such as product type, shelf life requirements, and storage conditions. Vacuum packing removes air to prevent oxidation and microbial growth, making it ideal for extending freshness of meats and cheeses, while Modified Atmosphere Packaging (MAP) modifies the gas composition inside the package to slow spoilage for fresh produce and baked goods. Your decision should consider the sensitivity of the product to oxygen, desired shelf life, and packaging costs to ensure optimal preservation and quality.

Vacuum packing vs MAP (Modified Atmosphere Packaging) Infographic

libmatt.com

libmatt.com