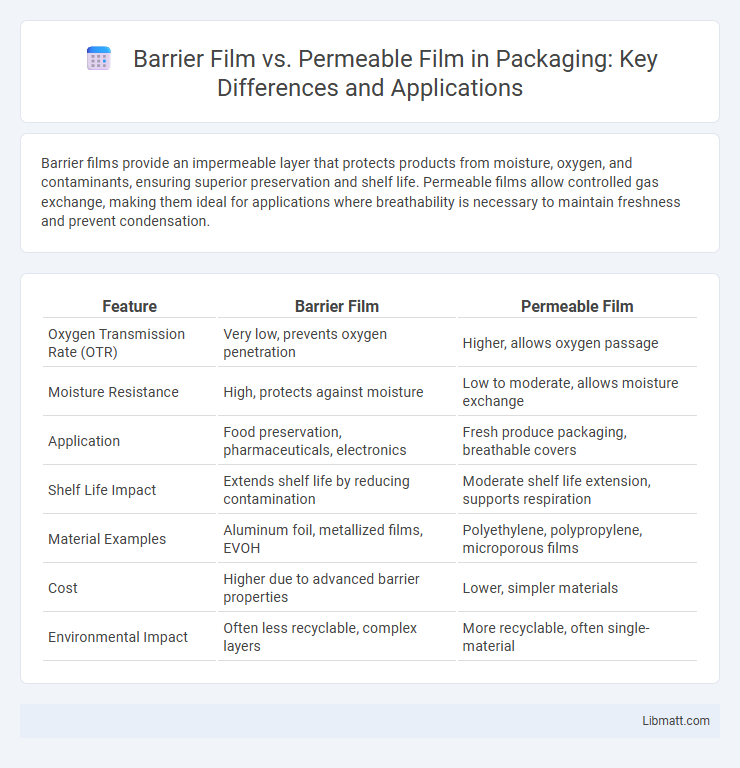

Barrier films provide an impermeable layer that protects products from moisture, oxygen, and contaminants, ensuring superior preservation and shelf life. Permeable films allow controlled gas exchange, making them ideal for applications where breathability is necessary to maintain freshness and prevent condensation.

Table of Comparison

| Feature | Barrier Film | Permeable Film |

|---|---|---|

| Oxygen Transmission Rate (OTR) | Very low, prevents oxygen penetration | Higher, allows oxygen passage |

| Moisture Resistance | High, protects against moisture | Low to moderate, allows moisture exchange |

| Application | Food preservation, pharmaceuticals, electronics | Fresh produce packaging, breathable covers |

| Shelf Life Impact | Extends shelf life by reducing contamination | Moderate shelf life extension, supports respiration |

| Material Examples | Aluminum foil, metallized films, EVOH | Polyethylene, polypropylene, microporous films |

| Cost | Higher due to advanced barrier properties | Lower, simpler materials |

| Environmental Impact | Often less recyclable, complex layers | More recyclable, often single-material |

Introduction to Barrier and Permeable Films

Barrier films are specialized materials designed to block the passage of gases, moisture, and vapors, making them essential in packaging applications that require extended shelf life and protection against environmental factors. Permeable films, in contrast, allow selective transmission of gases and moisture, facilitating breathability and preventing condensation, which is crucial in applications like food packaging and agriculture. Understanding the distinct properties of barrier and permeable films enables optimized material selection based on the specific permeability requirements of the product or environment.

Defining Barrier Films: Properties and Uses

Barrier films are specialized materials designed to block the passage of gases, moisture, and contaminants, featuring low permeability and high tensile strength for effective protection. Commonly used in food packaging, pharmaceuticals, and electronics, these films preserve product integrity by preventing oxidation and spoilage. Compared to permeable films, barrier films provide a critical environmental shield, extending shelf life and maintaining quality in sensitive applications.

Understanding Permeable Films: Features and Applications

Permeable films are designed to allow the passage of gases, moisture, and vapors while providing a protective barrier against contaminants, making them ideal for packaging fresh produce and medical supplies. Their microporous structure enhances breathability, reducing condensation and extending product shelf life. Common materials include polyethylene and polypropylene, favored for their flexibility and compatibility with various printing technologies.

Key Differences Between Barrier and Permeable Films

Barrier films provide superior protection by blocking gases, moisture, and contaminants, making them ideal for preserving perishable goods and sensitive products. Permeable films allow selective passage of air and moisture, enabling breathability which benefits applications like food packaging and medical dressings. Understanding your product's needs helps determine whether the impermeability of a barrier film or the breathability of a permeable film is the optimal choice.

Material Composition and Manufacturing Processes

Barrier films are typically composed of multilayer polymer structures such as polyethylene terephthalate (PET), aluminum foil, and metal oxides, designed to provide high resistance to oxygen, moisture, and chemical penetration. Permeable films are often made from single or blended polymers like polyethylene or polypropylene, manufactured through extrusion or blown film processes that allow selective gas and vapor transmission. Understanding the distinct material compositions and production methods helps you select the appropriate film based on the required barrier properties and application needs.

Moisture and Gas Transmission Rates Compared

Barrier films exhibit significantly lower moisture vapor transmission rates (MVTR) and oxygen transmission rates (OTR) compared to permeable films, effectively limiting moisture and gas ingress to preserve product integrity. Permeable films allow controlled transmission of water vapor and gases, which can be beneficial for applications requiring breathability or moisture release. Selection between barrier and permeable films depends on specific environmental protection needs, with barrier films preferred for high-moisture and oxygen-sensitive products.

Performance in Packaging and Preservation

Barrier films provide superior protection against moisture, oxygen, and contaminants, ensuring extended shelf life and maintaining product freshness in packaging applications. Permeable films allow controlled gas exchange, which is beneficial for packaging fresh produce by reducing condensation and preserving natural respiration. Your choice depends on the specific preservation needs and product sensitivity to environmental factors.

Environmental Impact and Sustainability

Barrier films, typically made from non-biodegradable polymers like polyethylene terephthalate (PET), offer superior protection against moisture and oxygen but present significant environmental challenges due to their persistence in landfills and difficulties in recycling. Permeable films, often biodegradable or compostable materials such as polylactic acid (PLA) or cellulose-based films, reduce environmental impact by allowing gas exchange and supporting composting processes, thereby contributing to sustainable packaging solutions. The choice between the two significantly influences a product's carbon footprint and waste management strategies in industries prioritizing eco-friendly practices.

Industry Standards and Testing Methods

Barrier films and permeable films are evaluated according to stringent industry standards such as ASTM and ISO, which specify criteria for oxygen transmission rates (OTR), moisture vapor transmission rates (MVTR), and chemical resistance. Testing methods for barrier films often include gravimetric analysis and gas chromatography to measure their effectiveness in preventing gas or moisture permeation, while permeable films undergo permeability tests that assess air and moisture flow to ensure breathability. Your choice between barrier and permeable films should consider these standardized performance metrics to ensure optimal product protection and compliance in applications like food packaging and medical supplies.

Choosing the Right Film for Your Application

Barrier films provide superior protection against moisture, oxygen, and contaminants, making them ideal for food packaging and electronics where product preservation is critical. Permeable films allow gas and vapor exchange, suitable for applications like agricultural mulch or breathable medical dressings that require controlled moisture balance. Selecting the right film depends on environmental exposure, product sensitivity, and required shelf life, ensuring optimal performance and cost efficiency.

Barrier film vs permeable film Infographic

libmatt.com

libmatt.com