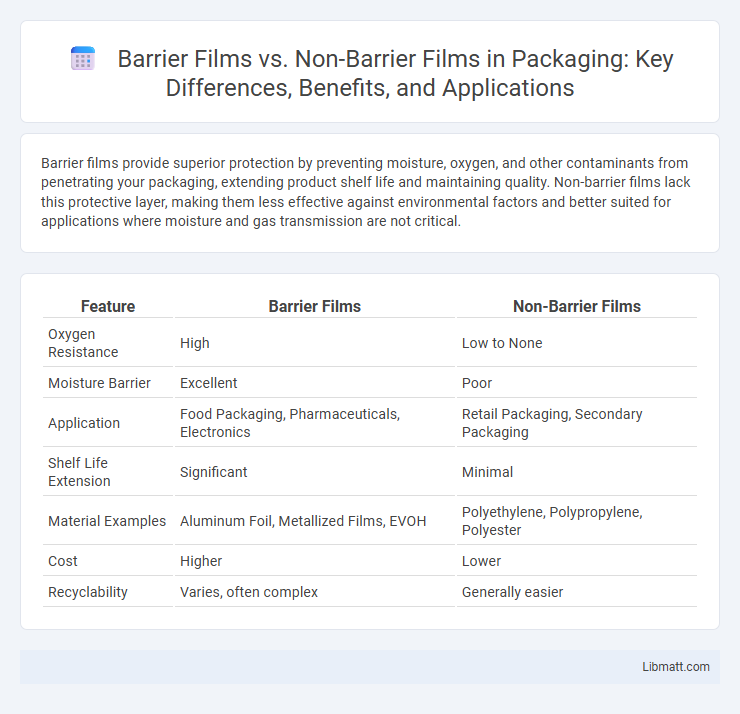

Barrier films provide superior protection by preventing moisture, oxygen, and other contaminants from penetrating your packaging, extending product shelf life and maintaining quality. Non-barrier films lack this protective layer, making them less effective against environmental factors and better suited for applications where moisture and gas transmission are not critical.

Table of Comparison

| Feature | Barrier Films | Non-Barrier Films |

|---|---|---|

| Oxygen Resistance | High | Low to None |

| Moisture Barrier | Excellent | Poor |

| Application | Food Packaging, Pharmaceuticals, Electronics | Retail Packaging, Secondary Packaging |

| Shelf Life Extension | Significant | Minimal |

| Material Examples | Aluminum Foil, Metallized Films, EVOH | Polyethylene, Polypropylene, Polyester |

| Cost | Higher | Lower |

| Recyclability | Varies, often complex | Generally easier |

Introduction to Barrier Films and Non-Barrier Films

Barrier films are specialized materials designed to prevent the passage of gases, moisture, and odors, making them essential in food packaging, pharmaceuticals, and electronics for enhancing product shelf life and protection. Non-barrier films allow more permeability, often used where breathability or flexibility is prioritized, such as in produce packaging or disposable liners. The choice between barrier and non-barrier films depends on the specific application requirements, including the need for protection against environmental factors and cost-effectiveness.

Definition and Core Differences

Barrier films are specialized packaging materials designed to limit the transmission of gases, moisture, and aromas, preserving product freshness and extending shelf life. Non-barrier films lack this protective functionality, allowing higher permeability which can lead to faster spoilage or contamination. The core difference lies in their molecular structure and coating technology, which enables barrier films to provide enhanced protection against environmental factors compared to standard non-barrier films.

Material Composition and Structure

Barrier films are typically composed of multiple layers, including polymers like polyethylene terephthalate (PET) combined with metal oxides or aluminum to create an impermeable structure that protects against moisture, oxygen, and other gases. Non-barrier films primarily consist of single-layer polymers such as polyethylene or polypropylene, which offer flexibility but lack the enhanced protective qualities found in barrier films. Choosing the right film for your packaging needs depends on the material composition and structure, with barrier films providing superior preservation by limiting exposure to external elements.

Key Functional Properties

Barrier films exhibit excellent resistance to oxygen, moisture, and contaminants, making them ideal for preserving the freshness and shelf life of perishable goods. Non-barrier films primarily offer mechanical protection and flexibility without significant impermeability, suitable for applications where moisture or gas permeability is not critical. The selection between barrier and non-barrier films depends on the specific functional needs such as oxygen transmission rate (OTR), water vapor transmission rate (WVTR), and chemical resistance.

Applications in Packaging

Barrier films provide superior protection against moisture, oxygen, and contaminants, making them ideal for packaging perishable food, pharmaceuticals, and sensitive electronics. Non-barrier films, while more cost-effective, are better suited for applications where breathability or lower protection is acceptable, such as packaging dry goods or produce. Choosing the right type of film ensures your products maintain freshness and quality throughout storage and transportation.

Moisture and Gas Permeability Comparison

Barrier films exhibit significantly lower moisture and gas permeability compared to non-barrier films, making them ideal for applications requiring extended shelf life and protection from environmental factors. The tightly packed polymer layers in barrier films reduce the transmission rates of oxygen, carbon dioxide, and water vapor, which are critical in food and pharmaceutical packaging. Non-barrier films, often made from simpler polyethylene or polypropylene, allow higher permeability, leading to faster degradation or spoilage of sensitive products.

Shelf Life and Product Protection

Barrier films significantly extend shelf life by limiting oxygen, moisture, and microbial infiltration, which preserves product freshness and quality over time. Non-barrier films offer minimal protection, making products more susceptible to spoilage, contamination, and degradation due to environmental exposure. Superior gas and vapor barrier properties in barrier films enhance product protection by maintaining optimal storage conditions and reducing oxidative damage.

Environmental Impact and Sustainability

Barrier films significantly reduce oxygen and moisture transmission, enhancing product shelf life and minimizing food waste, which contributes to lower overall environmental impact. Non-barrier films, often made from single-layer plastics, tend to degrade faster but usually have simpler recycling processes, affecting their sustainability profile. Advances in biodegradable barrier films aim to combine effective protection with eco-friendly disposal, addressing both preservation and environmental concerns.

Cost Considerations and Market Trends

Barrier films offer superior protection against moisture, oxygen, and contaminants, often justifying their higher cost in industries like food packaging and pharmaceuticals. Non-barrier films are more economical and commonly used where protection requirements are minimal, appealing to budget-conscious applications. Your choice depends on balancing cost efficiency and performance needs, with market trends showing increasing demand for sustainable and high-performance barrier films.

Choosing the Right Film for Your Application

Barrier films, designed with materials like aluminum foil or metallized layers, provide superior protection against moisture, oxygen, and contaminants, making them ideal for food packaging and pharmaceutical applications requiring extended shelf life. Non-barrier films, often composed of polyethylene or polypropylene, offer cost-effective solutions with flexibility and breathability, suitable for packaging fresh produce or non-perishable items where protection is less critical. Selecting the right film depends on specific application needs such as product sensitivity, required shelf life, and environmental exposure to ensure optimal performance and cost-efficiency.

Barrier films vs non-barrier films Infographic

libmatt.com

libmatt.com