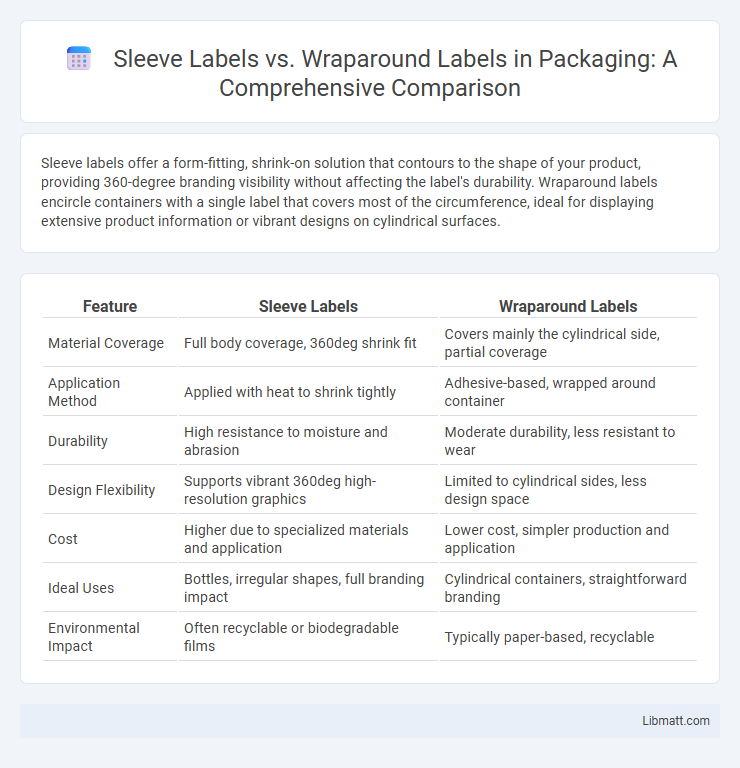

Sleeve labels offer a form-fitting, shrink-on solution that contours to the shape of your product, providing 360-degree branding visibility without affecting the label's durability. Wraparound labels encircle containers with a single label that covers most of the circumference, ideal for displaying extensive product information or vibrant designs on cylindrical surfaces.

Table of Comparison

| Feature | Sleeve Labels | Wraparound Labels |

|---|---|---|

| Material Coverage | Full body coverage, 360deg shrink fit | Covers mainly the cylindrical side, partial coverage |

| Application Method | Applied with heat to shrink tightly | Adhesive-based, wrapped around container |

| Durability | High resistance to moisture and abrasion | Moderate durability, less resistant to wear |

| Design Flexibility | Supports vibrant 360deg high-resolution graphics | Limited to cylindrical sides, less design space |

| Cost | Higher due to specialized materials and application | Lower cost, simpler production and application |

| Ideal Uses | Bottles, irregular shapes, full branding impact | Cylindrical containers, straightforward branding |

| Environmental Impact | Often recyclable or biodegradable films | Typically paper-based, recyclable |

Introduction to Sleeve and Wraparound Labels

Sleeve labels are shrinkable plastic films that conform tightly around a product, offering 360-degree branding and tamper-evident protection. Wraparound labels are flexible paper or plastic materials wrapped and adhered around a container, providing cost-effective branding with partial or full product coverage. Choosing between sleeve and wraparound labels depends on the product shape, marketing needs, and budget constraints.

Key Differences Between Sleeve and Wraparound Labels

Sleeve labels cover the entire circumference of a container, offering 360-degree branding opportunities with a seamless, tamper-evident design, while wraparound labels partially encircle the container, leaving portions of the surface visible and often using adhesive points for attachment. Sleeve labels excel in durability and water resistance due to their shrink-fit application, making them ideal for complex shapes and high-impact environments, whereas wraparound labels provide cost-effective, versatile branding suited for cylindrical containers with standard surfaces. Your choice depends on the desired visual impact, product shape, and budget constraints, as sleeve labels offer premium coverage and protection, while wraparound labels prioritize simplicity and affordability.

Material Options for Sleeve and Wraparound Labels

Sleeve labels are typically made from stretchable materials such as polyethylene, PVC, or PET, allowing them to conform tightly to various container shapes. Wraparound labels often utilize paper, polypropylene, or BOPP (biaxially oriented polypropylene), offering durability and resistance to moisture and chemicals. Both label types provide versatile material options tailored to specific packaging requirements and environmental conditions.

Printing Techniques for Both Label Types

Sleeve labels use heat-shrink technology that forms a 360-degree fit with vibrant, full-color printing achieved through rotogravure or flexographic methods, ideal for complex images and gradient effects. Wraparound labels employ adhesive-backed materials printed via flexographic or digital printing, allowing precise alignment and cost efficiency for high-volume production. Your choice of printing technique impacts label durability and visual appeal, with sleeve labels offering seamless, tamper-evident coverage and wraparound labels providing targeted branding on container surfaces.

Design Flexibility and Visual Appeal

Sleeve labels offer superior design flexibility with 360-degree coverage that enhances visual appeal through vibrant, full-color printing and unique textures that conform seamlessly to container shapes. Wraparound labels provide a more traditional look but can be limited by the container's circumference, restricting design size and detail. Choosing sleeve labels allows your brand to create eye-catching, dynamic packaging that stands out on the shelf while maintaining durability and a sleek finish.

Application Processes and Machinery Requirements

Sleeve labels require specialized heat-shrinking machinery to conform tightly around product contours, ensuring a seamless appearance, whereas wraparound labels use standard labeling machines that apply adhesive labels around containers. Sleeve labeling demands precise temperature control for shrinking films, increasing machinery complexity and operational costs compared to the simpler, faster application of wraparound labels. Both methods rely on automated equipment, but sleeve labels necessitate additional components like tunnels or shrink ovens, unlike the straightforward labeling heads used for wraparound applications.

Cost Considerations and Budget Impact

Sleeve labels generally incur higher costs due to their complex shrinking process and specialized materials, impacting your packaging budget more significantly than wraparound labels. Wraparound labels offer a cost-effective alternative by using simpler application methods and less expensive materials, making them ideal for businesses aiming to reduce expenses. Choosing between sleeve and wraparound labels depends on balancing visual appeal against budget constraints while considering production and material costs.

Sustainability and Environmental Factors

Sleeve labels are often more sustainable due to their reduced material usage and compatibility with recyclable PET, whereas wraparound labels typically use more adhesive and plastic, impacting recyclability. Sleeve labels fit snugly over products, allowing for better separation during recycling, while wraparound labels can contaminate paper or plastic streams. Choosing sleeve labels can enhance your product's environmental profile by minimizing waste and facilitating eco-friendly disposal.

Suitability for Different Packaging Shapes and Products

Sleeve labels conform seamlessly to curved or irregular packaging shapes, making them ideal for bottles, jars, and containers with contours, enhancing visual appeal and product identification. Wraparound labels provide full coverage around cylindrical products, offering ample space for branding and detailed information, commonly used for cans and bottles with standard shapes. Your choice between sleeve and wraparound labels depends on the container's geometry and the extent of design or information coverage needed.

Choosing the Right Label Type for Your Brand

Sleeve labels offer 360-degree coverage that enhances brand visibility and allows for intricate designs, making them ideal for products requiring high-impact presentation and tamper evidence. Wraparound labels provide a cost-efficient solution with full body coverage suitable for cylindrical containers, ensuring brand consistency through seamless graphics and easy application. Selecting between sleeve and wraparound labels depends on your product shape, budget, and the level of customization needed to effectively convey your brand identity.

Sleeve labels vs wraparound labels Infographic

libmatt.com

libmatt.com