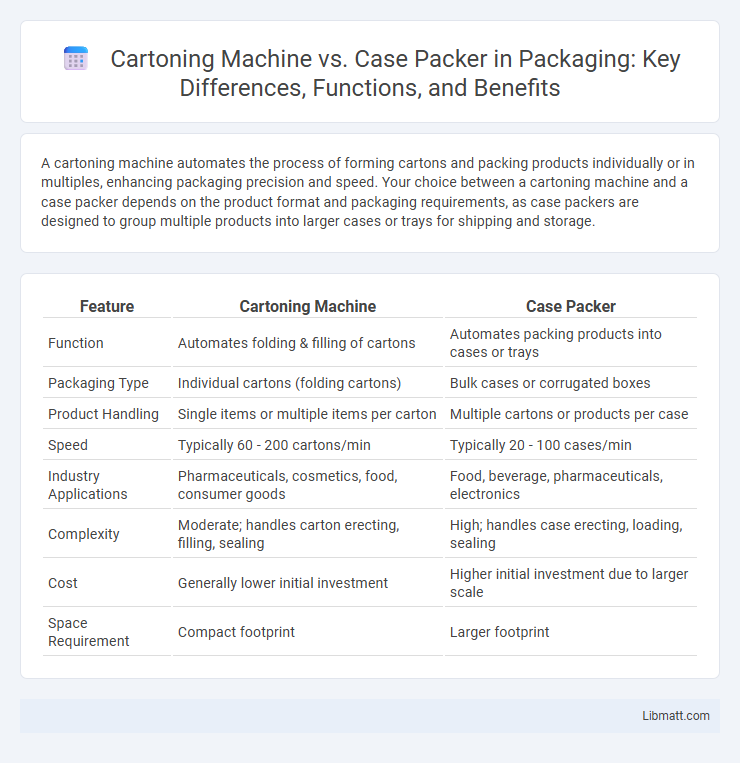

A cartoning machine automates the process of forming cartons and packing products individually or in multiples, enhancing packaging precision and speed. Your choice between a cartoning machine and a case packer depends on the product format and packaging requirements, as case packers are designed to group multiple products into larger cases or trays for shipping and storage.

Table of Comparison

| Feature | Cartoning Machine | Case Packer |

|---|---|---|

| Function | Automates folding & filling of cartons | Automates packing products into cases or trays |

| Packaging Type | Individual cartons (folding cartons) | Bulk cases or corrugated boxes |

| Product Handling | Single items or multiple items per carton | Multiple cartons or products per case |

| Speed | Typically 60 - 200 cartons/min | Typically 20 - 100 cases/min |

| Industry Applications | Pharmaceuticals, cosmetics, food, consumer goods | Food, beverage, pharmaceuticals, electronics |

| Complexity | Moderate; handles carton erecting, filling, sealing | High; handles case erecting, loading, sealing |

| Cost | Generally lower initial investment | Higher initial investment due to larger scale |

| Space Requirement | Compact footprint | Larger footprint |

Understanding Cartoning Machines and Case Packers

Cartoning machines are designed to automate the process of forming cartons, loading products, and sealing them, ideal for packaging individual items neatly in boxes. Case packers handle grouping multiple cartons or products into larger corrugated cases or trays for efficient shipping and storage. Understanding the differences helps you select the right equipment to streamline your packaging line and optimize production efficiency.

Key Differences Between Cartoning Machines and Case Packers

Cartoning machines primarily package products into cartons, offering precision in folding and sealing for smaller to medium-sized items, while case packers are designed to group multiple cartons or products into larger corrugated cases for shipping and storage. Cartoning machines excel in handling delicate or irregularly shaped products with detailed packaging requirements, whereas case packers focus on high-speed case formation, loading, and sealing to optimize logistics efficiency. Understanding these key differences helps you select the right equipment to balance packaging quality and throughput in your production line.

How Cartoning Machines Work

Cartoning machines automate the packaging process by erecting, filling, and sealing cartons with products in a streamlined sequence, optimizing speed and consistency. Utilizing mechanical arms, conveyors, and sensors, these machines precisely position items into folded cartons, ensuring minimal product damage and efficient space use. The integration of automated controls and vision systems enables real-time quality checks and adapts to various carton sizes and product types for versatile packaging solutions.

Case Packer Mechanisms Explained

Case packers utilize automated mechanisms such as rotary, inline, and gantry systems to efficiently place products into cases, ensuring high-speed and precise packaging. These machines often integrate robotic arms, conveyor belts, and servo-driven components to handle various product sizes and configurations. The mechanisms prioritize product integrity and packaging consistency, distinguishing case packers from cartoning machines, which focus primarily on folding and sealing cartons rather than full case assembly.

Applications: When to Use Cartoning Machines

Cartoning machines are ideal for packaging individual products such as pharmaceuticals, cosmetics, and food items that require precise and delicate handling within cartons. These machines excel in applications demanding high-speed, automated folding, and filling of cartons to ensure product protection and presentation. In contrast to case packers, which bundle multiple cartons into larger shipping cases, cartoning machines focus on the initial packaging stage, making them essential when immediate product-level packaging is necessary.

Applications: Ideal Scenarios for Case Packers

Case packers are ideal for high-volume production lines requiring efficient packaging of multiple products into larger shipping containers, ensuring streamlined logistics and reduced labor costs. You will often find case packers in industries like food and beverage, pharmaceuticals, and consumer goods where consistent product orientation and protection during transit are critical. Unlike cartoning machines, which excel at individual product packaging, case packers focus on grouping packaged units, optimizing warehouse space and shipment handling.

Efficiency and Speed Comparison

Cartoning machines typically offer higher speed and efficiency for handling lightweight products by automating the folding and filling of cartons at rapid rates, often exceeding 100 cartons per minute. Case packers excel in packing larger or heavier items into secondary packaging such as corrugated cases, generally operating at slower speeds due to the complexity of handling varied product sizes and weights. Your choice depends on balancing production volume needs and product specifications to optimize overall packaging line efficiency.

Packaging Flexibility and Customization Options

Cartoning machines offer high packaging flexibility, accommodating a wide variety of carton sizes, shapes, and product types, which allows for extensive customization in labeling and branding. Case packers excel in handling bulk packaging tasks with less variation, optimizing for speed and efficiency when packing uniform cases, but provide limited customization options compared to cartoning machines. Industries with diverse product lines benefit more from cartoning machines, while high-volume, standardized packaging is better suited for case packers.

Cost Considerations: Cartoning Machine vs Case Packer

Cartoning machines generally have lower upfront costs compared to case packers due to their simpler mechanism designed for packaging products into cartons rather than assembling and sealing larger cases. Operating expenses for cartoning machines can be reduced by faster changeover times and lower maintenance requirements, whereas case packers typically involve higher energy consumption and spare parts costs due to their complex automation systems. Investing in a case packer is often justified for higher-volume operations requiring robust packaging capabilities, despite the increased capital expenditure and operating costs.

Choosing the Right Solution for Your Packaging Line

Choosing the right packaging equipment depends on your product type and production speed; cartoning machines excel at efficiently forming cartons around individual products or small groups, enhancing product presentation and protection. Case packers are designed to handle larger volumes by grouping multiple cartons or products into cases for shipping, streamlining palletizing and logistics. Assessing your packaging line's capacity and end-use requirements ensures you invest in the solution that maximizes efficiency and meets your operational goals.

Cartoning machine vs case packer Infographic

libmatt.com

libmatt.com