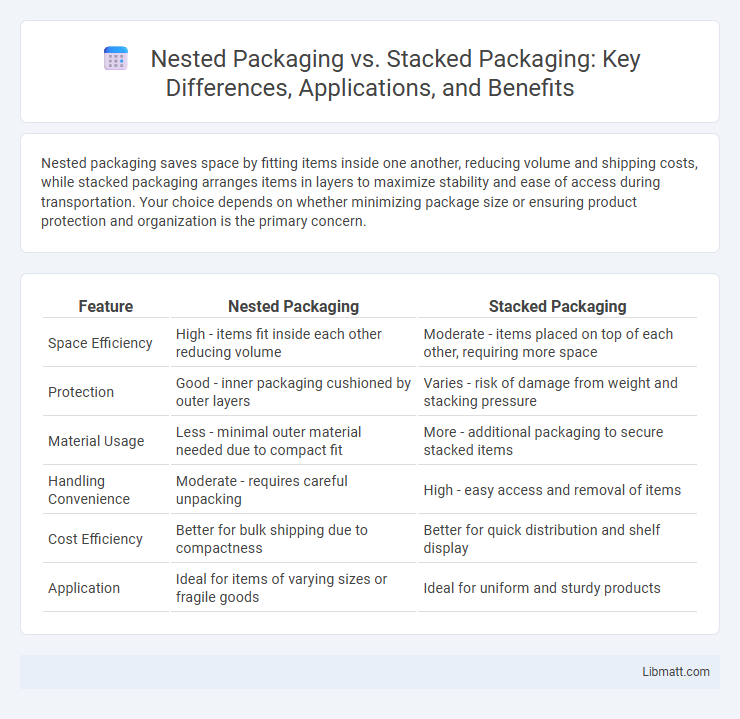

Nested packaging saves space by fitting items inside one another, reducing volume and shipping costs, while stacked packaging arranges items in layers to maximize stability and ease of access during transportation. Your choice depends on whether minimizing package size or ensuring product protection and organization is the primary concern.

Table of Comparison

| Feature | Nested Packaging | Stacked Packaging |

|---|---|---|

| Space Efficiency | High - items fit inside each other reducing volume | Moderate - items placed on top of each other, requiring more space |

| Protection | Good - inner packaging cushioned by outer layers | Varies - risk of damage from weight and stacking pressure |

| Material Usage | Less - minimal outer material needed due to compact fit | More - additional packaging to secure stacked items |

| Handling Convenience | Moderate - requires careful unpacking | High - easy access and removal of items |

| Cost Efficiency | Better for bulk shipping due to compactness | Better for quick distribution and shelf display |

| Application | Ideal for items of varying sizes or fragile goods | Ideal for uniform and sturdy products |

Introduction to Nested vs Stacked Packaging

Nested packaging involves placing items within one another to minimize space and enhance protection, ideal for irregularly shaped products requiring compact storage. Stacked packaging arranges items vertically or horizontally in layers, optimizing stability and ease of transportation for uniform products. Understanding the differences helps you select the best method to maximize efficiency and reduce shipping costs.

Defining Nested Packaging

Nested packaging optimizes space by fitting items within each other, reducing volume and material usage. It is ideal for irregularly shaped products that can be securely placed inside one another to minimize shipping costs. This method contrasts with stacked packaging, which arranges items vertically without internal placement, often requiring more protective padding.

Understanding Stacked Packaging

Stacked packaging arranges products vertically, maximizing space and improving inventory management by allowing easy access and visibility. This method enhances protection during transportation by distributing weight evenly and reducing movement, ensuring your items remain secure. Understanding stacked packaging helps optimize storage efficiency and reduce shipping costs in various industries.

Key Differences Between Nested and Stacked Packaging

Nested packaging involves placing smaller items within larger ones to minimize volume and enhance protection by eliminating void spaces. Stacked packaging arranges items directly on top of each other, optimizing vertical space but potentially increasing the risk of damage due to pressure points. Nested packaging is ideal for fragile products requiring cushioning, while stacked packaging suits uniform, durable goods where maximizing quantity per shipment is key.

Applications of Nested Packaging

Nested packaging is widely used in industries requiring efficient space utilization and enhanced product protection, such as electronics, cosmetics, and food sectors. Its design allows items to fit securely within one another, reducing material usage and minimizing shipping costs. You benefit from improved product presentation and easier handling, making nested packaging ideal for fragile or irregularly shaped goods.

Common Uses for Stacked Packaging

Stacked packaging is commonly used for products that require efficient space utilization and easy handling, such as canned goods, boxed items, and beverages. This method ensures stability during transportation and storage, reducing the risk of damage. Your supply chain can benefit from stacked packaging when dealing with bulk shipments in warehouses or retail environments where maximizing vertical space is crucial.

Advantages of Nested Packaging

Nested packaging offers significant space-saving benefits by efficiently fitting products within one another, reducing overall volume during storage and transportation. This method minimizes material usage and packaging costs while enhancing protection by preventing movement and damage. Your supply chain can improve sustainability and cost-effectiveness through reduced packaging waste and optimized shipping efficiency.

Benefits of Stacked Packaging

Stacked packaging maximizes storage efficiency by allowing products to be securely piled, reducing wasted space during transport and warehousing. It enhances stability, minimizing damage risks through uniform weight distribution and easier handling. Your supply chain benefits from quicker loading and unloading, leading to cost savings and improved operational workflows.

Factors to Consider When Choosing Packaging Methods

Choosing between nested packaging and stacked packaging depends on factors such as product fragility, space efficiency, and transportation costs. Nested packaging offers better protection and minimizes movement, ideal for delicate items, while stacked packaging maximizes storage space but may increase the risk of damage. Understanding your product's size, weight, and handling requirements helps determine the most effective packaging method for your supply chain.

Conclusion: Selecting the Right Packaging Approach

Selecting the right packaging approach depends on factors such as product type, shipping efficiency, and storage requirements. Nested packaging offers space-saving benefits and protection for fragile items by fitting smaller components inside larger ones, while stacked packaging maximizes vertical space and stability during transport. Analyzing product dimensions, handling conditions, and environmental impact ensures optimal packaging selection for cost-effectiveness and sustainability.

Nested packaging vs stacked packaging Infographic

libmatt.com

libmatt.com