Monomeric PVC consists of individual vinyl chloride monomers that have not yet undergone polymerization, resulting in a less durable and more rigid material primarily used for temporary applications. Polymeric PVC, formed by the polymerization of monomeric units, offers enhanced flexibility, strength, and chemical resistance, making it ideal for long-lasting products such as pipes, window frames, and cables.

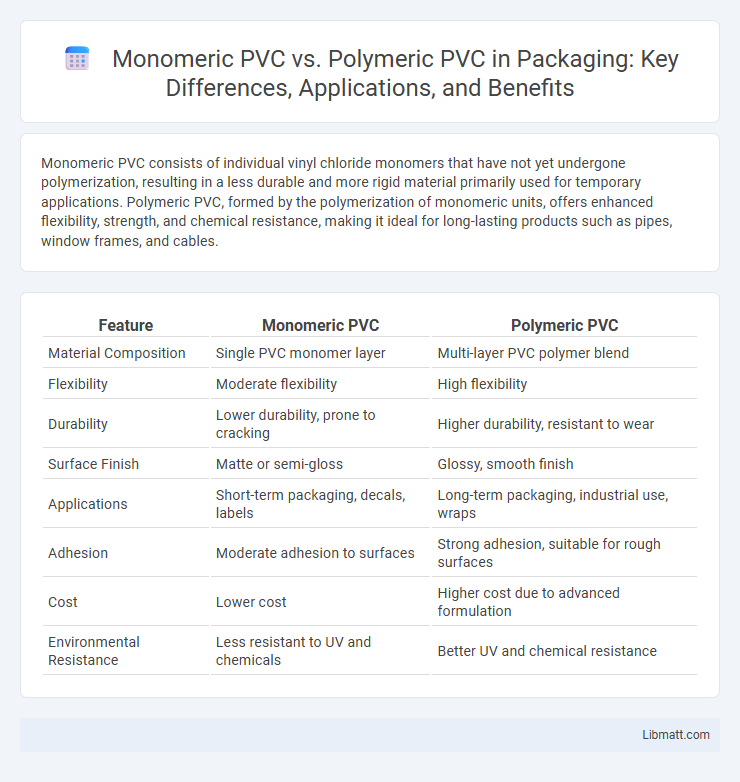

Table of Comparison

| Feature | Monomeric PVC | Polymeric PVC |

|---|---|---|

| Material Composition | Single PVC monomer layer | Multi-layer PVC polymer blend |

| Flexibility | Moderate flexibility | High flexibility |

| Durability | Lower durability, prone to cracking | Higher durability, resistant to wear |

| Surface Finish | Matte or semi-gloss | Glossy, smooth finish |

| Applications | Short-term packaging, decals, labels | Long-term packaging, industrial use, wraps |

| Adhesion | Moderate adhesion to surfaces | Strong adhesion, suitable for rough surfaces |

| Cost | Lower cost | Higher cost due to advanced formulation |

| Environmental Resistance | Less resistant to UV and chemicals | Better UV and chemical resistance |

Introduction to Monomeric and Polymeric PVC

Monomeric PVC consists of single-layer films made from polyvinyl chloride resin, offering flexibility and ease of application, ideal for short- to medium-term uses. Polymeric PVC features multi-layered films with added plasticizers, providing enhanced durability, gloss, and longevity for long-term outdoor applications. Understanding the differences between monomeric and polymeric PVC helps you select the right material based on project lifespan and environmental exposure.

Chemical Structure Differences

Monomeric PVC consists of shorter polymer chains with simpler, less branched molecular structures, resulting in more rigid and less flexible properties. Polymeric PVC contains longer, more complex chains with greater molecular weight and higher degrees of polymerization, contributing to enhanced durability and flexibility. These chemical structure differences influence the material's mechanical performance and application versatility.

Manufacturing Processes

Monomeric PVC is produced through suspension polymerization, creating low molecular weight chains ideal for flexible and temporary applications like vehicle wraps and wall coverings. Polymeric PVC typically undergoes emulsion or bulk polymerization, resulting in higher molecular weight chains that provide enhanced durability and rigidity for long-term uses such as pipes and window frames. Your choice between monomeric and polymeric PVC should consider these manufacturing differences to align with the required product performance.

Physical Properties Comparison

Monomeric PVC exhibits lower tensile strength and flexibility compared to polymeric PVC, making it suitable for applications requiring rigid and durable materials. Polymeric PVC offers enhanced thermal stability, higher impact resistance, and better elongation properties due to its cross-linked molecular structure. The density of polymeric PVC typically ranges from 1.38 to 1.43 g/cm3, whereas monomeric PVC tends to be less dense, affecting its hardness and abrasion resistance.

Durability and Lifespan

Monomeric PVC offers moderate durability with a typical lifespan of 3 to 5 years, making it suitable for short-term applications or indoor use. Polymeric PVC features enhanced durability and a longer lifespan of up to 7 to 10 years, due to its added plasticizers that improve flexibility and resistance to environmental factors. Choosing polymeric PVC for your project ensures greater longevity and better performance in outdoor or high-wear conditions.

Application Areas

Monomeric PVC is widely used in short-term applications such as vehicle wraps, indoor signage, and promotional graphics due to its flexibility and ease of installation. Polymeric PVC, with higher molecular weight, offers superior durability and weather resistance, making it ideal for long-term applications like exterior signage, wall coverings, and vehicle graphics. The choice between monomeric and polymeric PVC primarily depends on the required lifespan and exposure conditions of the application.

Cost Considerations

Monomeric PVC typically incurs lower production costs due to simpler manufacturing processes and the use of less expensive raw materials. Polymeric PVC, while providing enhanced durability and performance, involves higher fabrication expenses stemming from complex polymerization techniques and additive incorporation. Budget-conscious projects often favor monomeric PVC for cost efficiency, whereas demands for longevity justify the premium price of polymeric PVC.

Environmental Impact

Monomeric PVC generally has a lower environmental impact during production due to its simpler manufacturing process and reduced use of plasticizers compared to polymeric PVC. Polymeric PVC, commonly used for durable applications, often contains additives that can release harmful chemicals during disposal or incineration, increasing environmental concerns. Your choice between monomeric and polymeric PVC should consider long-term sustainability and potential pollutant release throughout the material's lifecycle.

Performance in Outdoor and Indoor Uses

Monomeric PVC offers flexibility and cost-effectiveness, making it suitable for short-term indoor applications where minimal exposure to harsh weather conditions is expected. Polymeric PVC provides enhanced durability, UV resistance, and weatherability, making it ideal for long-term outdoor use, maintaining color and structural integrity under prolonged sunlight and temperature variations. Choosing polymeric PVC ensures better performance in environments that demand resistance against fading, cracking, and environmental stress compared to monomeric PVC.

Choosing Between Monomeric and Polymeric PVC

Choosing between monomeric and polymeric PVC depends on application requirements and durability needs. Monomeric PVC offers cost-effective short-term solutions with easier removal and flexibility for indoor or temporary uses, while polymeric PVC provides superior durability, chemical resistance, and longevity, ideal for outdoor signage and long-term installations. Assessing environmental exposure, adhesive strength, and project budget is essential to determine the optimal PVC type for performance and lifespan.

Monomeric PVC vs polymeric PVC Infographic

libmatt.com

libmatt.com