Steel drums offer superior durability and resistance to high temperatures, making them ideal for industrial storage and transportation of hazardous materials. Plastic drums provide lightweight, corrosion-resistant options suitable for storing chemicals and liquids while being easier to handle and cost-effective for your storage needs.

Table of Comparison

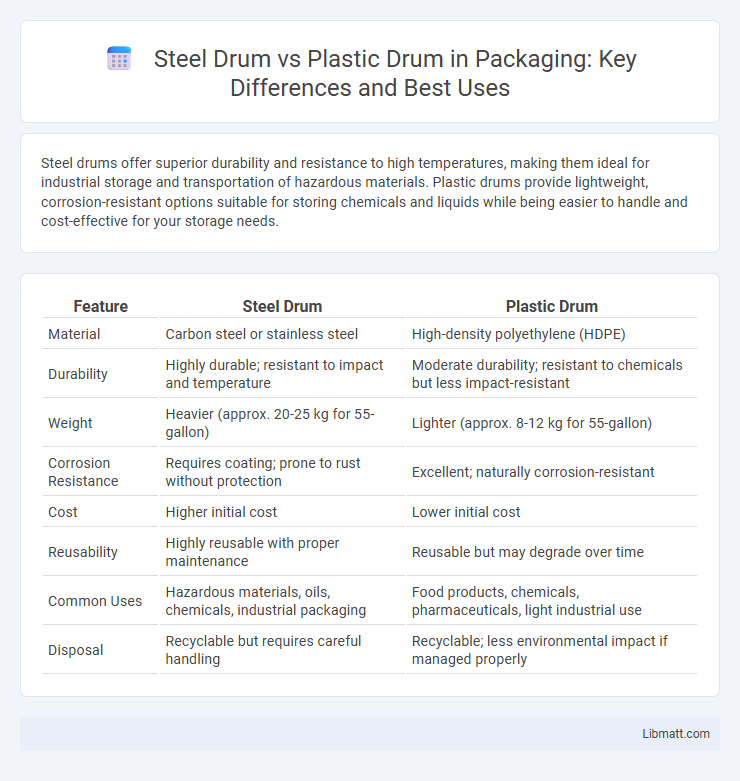

| Feature | Steel Drum | Plastic Drum |

|---|---|---|

| Material | Carbon steel or stainless steel | High-density polyethylene (HDPE) |

| Durability | Highly durable; resistant to impact and temperature | Moderate durability; resistant to chemicals but less impact-resistant |

| Weight | Heavier (approx. 20-25 kg for 55-gallon) | Lighter (approx. 8-12 kg for 55-gallon) |

| Corrosion Resistance | Requires coating; prone to rust without protection | Excellent; naturally corrosion-resistant |

| Cost | Higher initial cost | Lower initial cost |

| Reusability | Highly reusable with proper maintenance | Reusable but may degrade over time |

| Common Uses | Hazardous materials, oils, chemicals, industrial packaging | Food products, chemicals, pharmaceuticals, light industrial use |

| Disposal | Recyclable but requires careful handling | Recyclable; less environmental impact if managed properly |

Introduction to Steel Drums and Plastic Drums

Steel drums offer exceptional durability, resistance to impact, and are ideal for storing hazardous materials due to their robust construction and ability to withstand extreme conditions. Plastic drums are lightweight, corrosion-resistant, and more suitable for storing chemicals, food products, and liquids that require non-reactive containment. Your choice between steel and plastic drums depends on the specific storage needs, including material compatibility, durability, and environmental factors.

Material Composition and Durability

Steel drums consist of carbon steel or stainless steel, offering high durability, resistance to impact, and excellent protection against contamination, making them ideal for industrial storage and transportation. Plastic drums, typically made from high-density polyethylene (HDPE), provide superior resistance to chemicals, corrosion, and UV exposure but may be less impact-resistant compared to steel. Your choice depends on the specific material compatibility and durability requirements for your storage or shipping needs.

Weight and Handling Differences

Steel drums typically weigh between 40 to 50 pounds, making them heavier and more durable but harder to handle compared to plastic drums, which weigh approximately 20 to 30 pounds. The lighter weight of plastic drums enhances your ability to maneuver and transport them easily, especially in environments requiring frequent movement. Steel drums are better suited for heavy-duty applications but may require specialized equipment or additional effort for handling due to their weight.

Cost Comparison

Steel drums typically have a higher upfront cost compared to plastic drums due to the material and manufacturing process, but they offer superior durability and reuse potential. Plastic drums are generally more affordable initially, making them suitable for single-use or short-term storage applications, though they may degrade faster under harsh conditions. When considering total lifecycle cost, steel drums often prove more economical for long-term storage and transportation due to longevity and resistance to damage.

Corrosion and Chemical Resistance

Steel drums offer superior mechanical strength but are prone to corrosion when exposed to moisture or acidic chemicals, requiring protective coatings to enhance durability. Plastic drums excel in chemical resistance, particularly against acids, alkalis, and solvents, making them ideal for storing corrosive substances without rust risk. Choosing between steel and plastic drums depends on the specific chemical compatibility requirements and environmental exposure factors.

Environmental Impact and Sustainability

Steel drums are highly recyclable and offer greater durability, reducing the need for frequent replacements and minimizing landfill waste. Plastic drums, while lightweight and resistant to corrosion, often contribute to microplastic pollution and have lower recycling rates. To enhance your sustainability efforts, choosing steel drums can significantly reduce environmental impact through long-term reuse and efficient recycling processes.

Common Uses and Industry Applications

Steel drums are widely used in industries such as chemicals, petroleum, and hazardous waste due to their durability and ability to withstand high temperatures and pressure. Plastic drums find common applications in food processing, pharmaceuticals, and water treatment, favored for their corrosion resistance and lightweight properties. Your choice between steel and plastic drums should align with the specific requirements of the contents and industry standards.

Safety Considerations

Steel drums offer superior impact resistance and are less prone to punctures, making them ideal for storing hazardous materials where safety is critical. Plastic drums provide excellent chemical resistance and are lighter, reducing injury risk during handling but may be more susceptible to damage under high-pressure conditions. Your choice should consider the specific safety requirements of the stored contents and handling environment to minimize risks effectively.

Storage and Transportation Efficiency

Steel drums offer superior durability and resistance to punctures, making them ideal for heavy-duty storage and long-distance transportation of hazardous or bulk materials. Plastic drums are lighter and more corrosion-resistant, reducing shipping costs and simplifying handling, particularly for liquids and non-corrosive substances. Your choice between steel and plastic drums should consider the balance between weight efficiency and material protection for optimal storage and transport performance.

Conclusion: Choosing the Right Drum for Your Needs

Steel drums offer superior durability, chemical resistance, and protection for hazardous materials, making them ideal for heavy-duty industrial use. Plastic drums provide lightweight, corrosion-resistant, and cost-effective solutions, suitable for storing food, chemicals, and non-hazardous liquids. Your choice between steel and plastic drums should be guided by the specific requirements of durability, chemical compatibility, and budget constraints.

Steel drum vs plastic drum Infographic

libmatt.com

libmatt.com