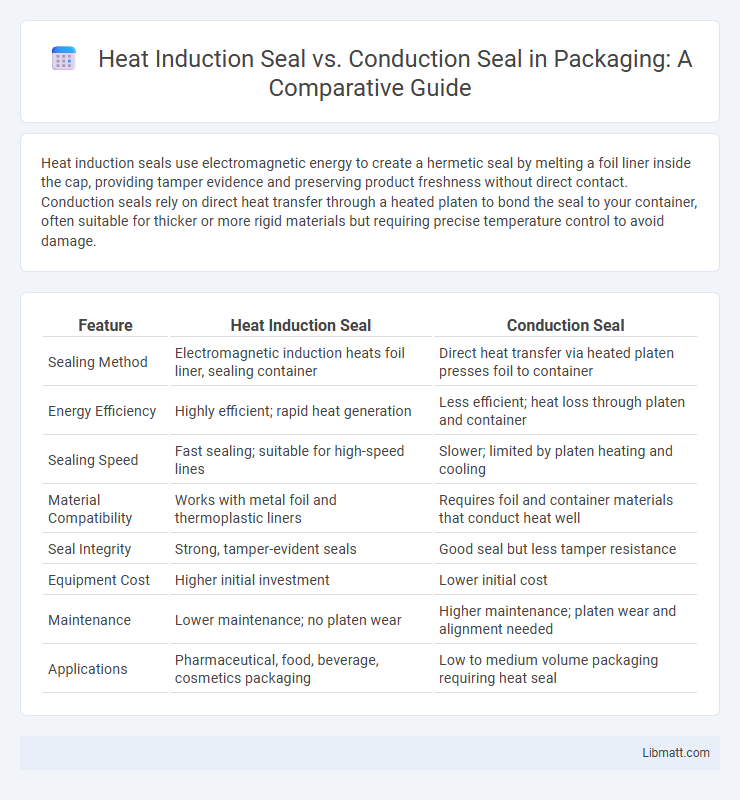

Heat induction seals use electromagnetic energy to create a hermetic seal by melting a foil liner inside the cap, providing tamper evidence and preserving product freshness without direct contact. Conduction seals rely on direct heat transfer through a heated platen to bond the seal to your container, often suitable for thicker or more rigid materials but requiring precise temperature control to avoid damage.

Table of Comparison

| Feature | Heat Induction Seal | Conduction Seal |

|---|---|---|

| Sealing Method | Electromagnetic induction heats foil liner, sealing container | Direct heat transfer via heated platen presses foil to container |

| Energy Efficiency | Highly efficient; rapid heat generation | Less efficient; heat loss through platen and container |

| Sealing Speed | Fast sealing; suitable for high-speed lines | Slower; limited by platen heating and cooling |

| Material Compatibility | Works with metal foil and thermoplastic liners | Requires foil and container materials that conduct heat well |

| Seal Integrity | Strong, tamper-evident seals | Good seal but less tamper resistance |

| Equipment Cost | Higher initial investment | Lower initial cost |

| Maintenance | Lower maintenance; no platen wear | Higher maintenance; platen wear and alignment needed |

| Applications | Pharmaceutical, food, beverage, cosmetics packaging | Low to medium volume packaging requiring heat seal |

Introduction to Heat Induction and Conduction Sealing

Heat induction sealing uses electromagnetic induction to generate heat within a metallic foil liner, creating a hermetic and tamper-evident seal on your container. Conduction sealing, by contrast, applies direct heat from a heated surface to melt the sealant, bonding it to the container rim. Both methods ensure product freshness and leakage prevention but differ in heat transfer mechanisms and equipment requirements.

How Heat Induction Sealing Works

Heat induction sealing works by applying an electromagnetic field that generates heat within a foil liner, causing it to bond securely to the container's rim and create an airtight seal. This process ensures tamper-evidence and preserves product freshness by preventing contamination and leakage. Your products benefit from this non-contact sealing method, which is fast, reliable, and ideal for various packaging materials.

How Conduction Sealing Works

Conduction sealing works by directly transferring heat from a heated sealing bar to the sealing foil and container surface, causing the adhesive layer to melt and bond securely. This precise heat application ensures a tight, tamper-evident seal ideal for various packaging materials such as plastic, glass, or metal containers. Your packaging efficiency improves as conduction sealing offers consistent temperature control and quick cycle times for reliable container sealing.

Key Differences Between Induction and Conduction Sealing

Heat induction seal uses electromagnetic induction to generate heat directly in the foil liner, creating a hermetic seal without contact, while conduction sealing relies on direct contact and pressure to transfer heat from a heated platen to the sealing surface. Induction sealing offers faster sealing speeds, improved seal integrity, and reduced risk of contamination, making it ideal for high-volume packaging lines. Your choice between induction and conduction sealing depends on factors such as container material, production speed, and the need for a tamper-evident barrier.

Advantages of Heat Induction Sealing

Heat induction sealing offers a non-contact application process that ensures a hermetic, tamper-evident seal without contaminating the product or container, making it ideal for sensitive pharmaceuticals and food packaging. This technology provides consistent, uniform sealing speed suitable for high-speed production lines, reducing downtime and increasing operational efficiency. The energy-efficient process minimizes heat exposure to the container, preserving material integrity and enhancing overall package durability compared to conduction sealing methods.

Advantages of Conduction Sealing

Conduction sealing offers precise heat control by transferring heat directly through a sealing plate, resulting in uniform seal integrity and reduced risk of product degradation. This method provides faster sealing cycles and energy efficiency compared to induction sealing, making it ideal for high-volume production lines. Your packaging process benefits from consistent seals that enhance product freshness and shelf life while minimizing operational costs.

Applications for Heat Induction Sealing

Heat induction sealing is widely used in food, pharmaceutical, and cosmetics industries to provide tamper-evident and airtight seals on containers, preserving product freshness and extending shelf life. This method is ideal for sealing plastic or glass containers with foil liners, especially for liquids, powders, and granulated products requiring contamination protection. Your packaging process benefits from heat induction sealing's fast, contactless application, ensuring efficient production without compromising seal integrity.

Applications for Conduction Sealing

Conduction sealing is widely used in pharmaceutical, food, and cosmetics industries due to its precise control over heat application, ensuring consistent seal integrity without damaging heat-sensitive products. Its direct heat transfer method makes conduction sealing ideal for sealing aluminum foil liners on plastic containers, preserving product freshness and preventing contamination. Your packaging process benefits from conduction sealing's efficiency in producing strong, tamper-evident seals suitable for various container types and materials.

Cost Comparison: Induction vs Conduction Sealing

Induction sealing typically involves higher initial equipment costs compared to conduction sealing due to the need for specialized induction coils and power supplies. However, induction sealing offers faster processing speeds and reduced energy consumption, resulting in lower operational costs over time. In contrast, conduction sealing generally has lower upfront costs but may incur higher energy expenses and slower throughput, making it less cost-efficient for high-volume packaging operations.

Choosing the Right Sealing Method for Your Needs

Selecting between heat induction seal and conduction seal depends on your product's packaging material and production speed requirements. Heat induction seals provide a strong, tamper-evident barrier suitable for high-speed automated lines, while conduction seals offer precise, direct heat application ideal for sensitive or thicker materials. Your choice should align with packaging integrity needs, sealing efficiency, and compatibility with your container type.

Heat induction seal vs conduction seal Infographic

libmatt.com

libmatt.com