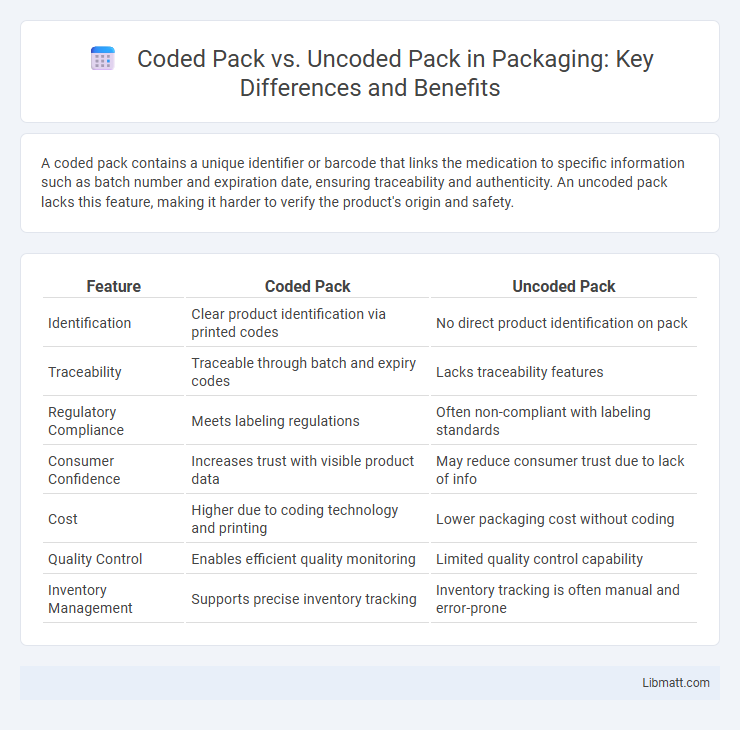

A coded pack contains a unique identifier or barcode that links the medication to specific information such as batch number and expiration date, ensuring traceability and authenticity. An uncoded pack lacks this feature, making it harder to verify the product's origin and safety.

Table of Comparison

| Feature | Coded Pack | Uncoded Pack |

|---|---|---|

| Identification | Clear product identification via printed codes | No direct product identification on pack |

| Traceability | Traceable through batch and expiry codes | Lacks traceability features |

| Regulatory Compliance | Meets labeling regulations | Often non-compliant with labeling standards |

| Consumer Confidence | Increases trust with visible product data | May reduce consumer trust due to lack of info |

| Cost | Higher due to coding technology and printing | Lower packaging cost without coding |

| Quality Control | Enables efficient quality monitoring | Limited quality control capability |

| Inventory Management | Supports precise inventory tracking | Inventory tracking is often manual and error-prone |

Introduction to Coded and Uncoded Packs

Coded packs refer to memory modules with internally organized register or buffer structures that distribute electrical loads, improving signal integrity and stability in high-density RAM configurations. Uncoded packs lack these registers or buffers, offering lower latency but reduced signal reliability, making them suitable for standard consumer applications with fewer memory modules. Understanding the distinction between coded and uncoded packs is critical for optimizing system performance and compatibility in server versus desktop environments.

Defining Coded Packs: Features and Uses

Coded packs contain predefined barcodes or QR codes that enable seamless product tracking, inventory management, and automated checkout processes. These packs are essential in retail and logistics for improving accuracy and efficiency by linking physical products directly to digital databases. Your business benefits from faster scanning, reduced errors, and enhanced supply chain visibility when using coded packs.

Understanding Uncoded Packs

Uncoded packs in telecommunications refer to data units transmitted without forward error correction (FEC), relying solely on inherent signal integrity and external error management techniques. Unlike coded packs that embed error-detecting and correcting information, uncoded packs optimize bandwidth by minimizing overhead but suffer higher susceptibility to transmission errors. Understanding uncoded packs is crucial for applications prioritizing speed and bandwidth efficiency over error resilience.

Key Differences Between Coded and Uncoded Packs

Coded packs feature a tracking system with barcodes or QR codes that enable inventory management, authenticity verification, and streamlined distribution, while uncoded packs lack these identifiers, making them harder to trace or confirm. The key difference lies in traceability: coded packs provide data on origin, batch number, and expiry dates, which enhances quality control and consumer safety. Your choice between coded and uncoded packs impacts supply chain transparency, counterfeit prevention, and regulatory compliance.

Advantages of Coded Packs

Coded packs offer enhanced security by reducing the risk of errors during shipping and inventory management through unique identifiers for each unit. These packs improve traceability and accountability in supply chains, facilitating quicker recall processes and better quality control. Furthermore, coded packs streamline automated systems in warehouses, increasing efficiency and accuracy in order fulfillment.

Benefits of Uncoded Packs

Uncoded packs offer greater flexibility for customization, allowing businesses to tailor packaging based on specific needs and preferences. They typically reduce inventory complexity and enable faster adaptation to changing market demands. Your operations benefit from cost savings and enhanced scalability when choosing uncoded packaging solutions.

Common Applications in Various Industries

Coded packs are widely utilized in pharmaceuticals and food industries for easy identification and traceability, ensuring compliance with regulatory standards. Uncoded packs are favored in manufacturing and logistics sectors where speed and volume handling take precedence over detailed tracking. Your choice between coded and uncoded packs depends on whether industry-specific requirements prioritize product information visibility or operational efficiency.

Cost Implications: Coded vs Uncoded Packs

Coded packs typically incur higher production costs due to the incorporation of unique identifiers or barcodes that facilitate tracking, inventory management, and anti-counterfeiting measures. Uncoded packs, lacking these features, are generally cheaper to produce but may lead to increased losses from theft, counterfeiting, and inefficient stock control. The cost implications of choosing coded over uncoded packs involve balancing upfront expenditures against long-term savings and operational efficiencies.

Regulatory and Compliance Considerations

Coded packs include unique identifiers such as serial numbers or barcodes that facilitate traceability and meet regulatory requirements for anti-counterfeiting and supply chain transparency. Uncoded packs lack this detailed identification, potentially leading to compliance issues with agencies that mandate product serialization, such as the FDA or EMA. Ensuring your products are in coded packs supports adherence to global regulatory standards and simplifies auditing processes.

Choosing the Right Option for Your Business

Choosing between a coded pack and an uncoded pack depends on your business's need for product traceability and inventory management. Coded packs offer unique identifiers that streamline tracking, enhance quality control, and simplify regulatory compliance, making them ideal for businesses prioritizing precision and accountability. Your choice should align with operational requirements and the value placed on data-driven inventory insights.

Coded pack vs uncoded pack Infographic

libmatt.com

libmatt.com