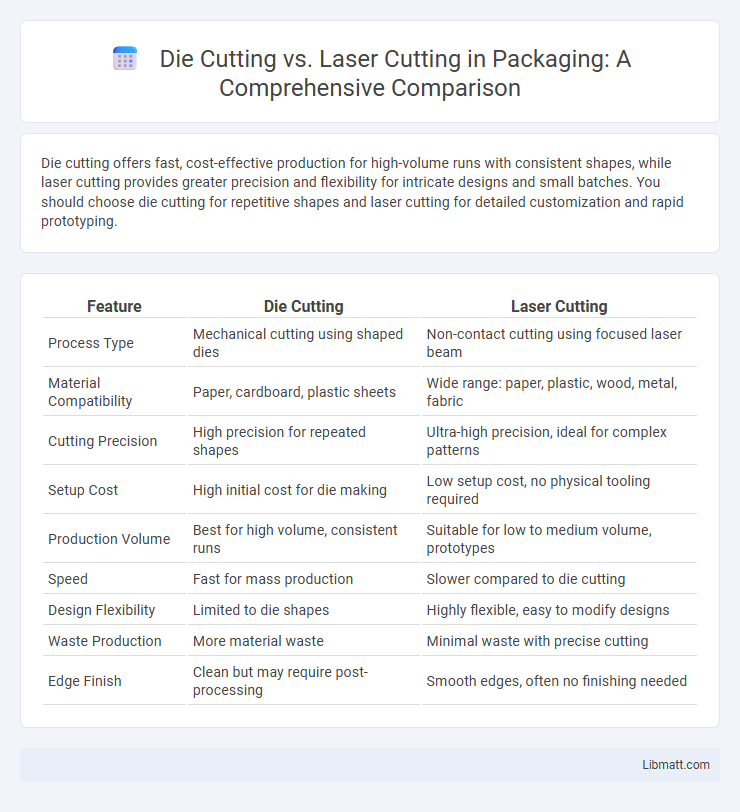

Die cutting offers fast, cost-effective production for high-volume runs with consistent shapes, while laser cutting provides greater precision and flexibility for intricate designs and small batches. You should choose die cutting for repetitive shapes and laser cutting for detailed customization and rapid prototyping.

Table of Comparison

| Feature | Die Cutting | Laser Cutting |

|---|---|---|

| Process Type | Mechanical cutting using shaped dies | Non-contact cutting using focused laser beam |

| Material Compatibility | Paper, cardboard, plastic sheets | Wide range: paper, plastic, wood, metal, fabric |

| Cutting Precision | High precision for repeated shapes | Ultra-high precision, ideal for complex patterns |

| Setup Cost | High initial cost for die making | Low setup cost, no physical tooling required |

| Production Volume | Best for high volume, consistent runs | Suitable for low to medium volume, prototypes |

| Speed | Fast for mass production | Slower compared to die cutting |

| Design Flexibility | Limited to die shapes | Highly flexible, easy to modify designs |

| Waste Production | More material waste | Minimal waste with precise cutting |

| Edge Finish | Clean but may require post-processing | Smooth edges, often no finishing needed |

Introduction to Die Cutting and Laser Cutting

Die cutting uses customized steel dies to stamp shapes from materials like paper, fabric, or plastic with high precision and speed, ideal for mass production. Laser cutting employs a focused laser beam to cut or engrave materials such as wood, acrylic, or metal, offering intricate detail and flexibility for complex designs. Your choice between die cutting and laser cutting depends on the material, design complexity, and production volume required.

Key Differences Between Die Cutting and Laser Cutting

Die cutting uses a physical die to stamp out shapes from materials, providing fast and cost-effective production for large volumes, whereas laser cutting employs a focused laser beam to precisely cut or engrave materials with high accuracy and minimal waste. Die cutting is ideal for repetitive, high-speed tasks involving softer materials like paper and fabric, while laser cutting accommodates a broader range of materials including metals, plastics, and wood, offering intricate detail and customization. The choice between die cutting and laser cutting depends on factors such as production volume, material type, design complexity, and cost efficiency.

Materials Suitable for Die Cutting and Laser Cutting

Die cutting excels with materials like paper, cardboard, rubber, and thin plastics, offering precise, repeatable shapes ideal for mass production. Laser cutting handles a broader range, including metals, wood, acrylic, and leather, allowing intricate designs and fine detail with minimal material stress. Your choice depends on the material's thickness, flexibility, and desired detail, making laser cutting ideal for complex patterns and die cutting preferable for high-volume runs on softer substrates.

Accuracy and Precision in Cutting Methods

Laser cutting offers superior accuracy and precision compared to die cutting, utilizing focused laser beams to achieve intricate and detailed cuts with minimal material distortion. Die cutting, while efficient for high-volume production, may produce slight variations due to mechanical pressure and die wear, affecting cutting consistency. Your choice depends on project requirements, where laser cutting excels in precision for customized designs and die cutting suits repetitive, standardized shapes.

Production Speed and Efficiency

Die cutting offers faster production speeds for high-volume runs due to its ability to quickly stamp out shapes using pre-made dies, making it highly efficient for large quantities. Laser cutting provides greater precision and flexibility for complex designs but operates at slower speeds, impacting overall efficiency in mass production. Your choice depends on balancing speed versus customization needs, with die cutting excelling in efficiency and laser cutting in detail.

Cost Comparison: Die Cutting vs Laser Cutting

Die cutting generally offers lower costs for high-volume production runs due to its reusable steel dies, making it ideal for businesses seeking efficiency in large-scale projects. Laser cutting involves higher upfront expense but excels in precision and customization without the need for physical dies, allowing you to reduce costs on small batches or intricate designs. Your choice depends on balancing setup costs and production volume to optimize overall expenses.

Design Flexibility and Complexity

Die cutting offers limited design flexibility due to fixed dies that restrict intricate shapes and rapid modifications, making it ideal for high-volume, repetitive patterns. Laser cutting provides exceptional design complexity and customization by using precise, computer-controlled beams to cut intricate details on various materials without physical tooling. Your choice depends on whether you prioritize mass production efficiency or intricate, highly customizable designs.

Applications in Various Industries

Die cutting excels in mass production industries such as packaging, automotive, and textiles due to its speed and cost-efficiency for repetitive shapes. Laser cutting is preferred in aerospace, electronics, and medical device manufacturing for its precision, ability to cut complex patterns, and suitability for diverse materials including metals and plastics. Both techniques play vital roles in enhancing production workflows by offering tailored cutting solutions based on material type, design complexity, and volume requirements.

Environmental Impact and Waste Considerations

Die cutting generates more physical waste due to the use of metal dies and material scrap, which often require landfill disposal or recycling efforts. Laser cutting produces minimal waste by precisely vaporizing material and allowing for better nesting of cuts, reducing offcuts and resource consumption. Energy consumption varies, with lasers typically using an electric power source that can be optimized with renewable energy, while die cutting relies on manual or mechanical force with less potential for clean energy integration.

Choosing the Right Cutting Method for Your Project

Die cutting offers high-volume precision and speed, making it ideal for repetitive shapes and standard materials like paper, cardboard, and thin metals. Laser cutting provides exceptional versatility and detail, cutting complex designs on various materials including wood, acrylic, and fabric, with minimal setup time. Your choice depends on project scale, material type, and detail complexity to ensure efficient production and high-quality results.

Die cutting vs laser cutting Infographic

libmatt.com

libmatt.com