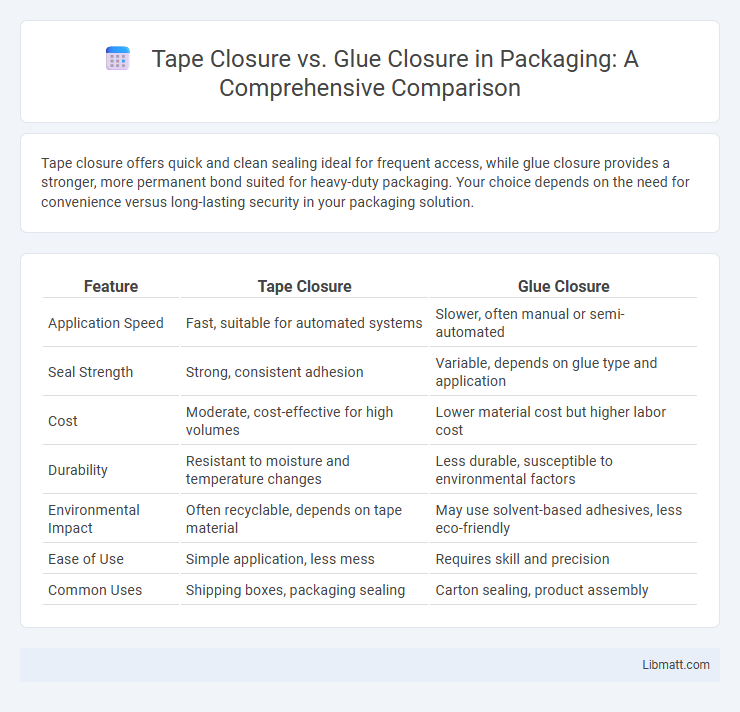

Tape closure offers quick and clean sealing ideal for frequent access, while glue closure provides a stronger, more permanent bond suited for heavy-duty packaging. Your choice depends on the need for convenience versus long-lasting security in your packaging solution.

Table of Comparison

| Feature | Tape Closure | Glue Closure |

|---|---|---|

| Application Speed | Fast, suitable for automated systems | Slower, often manual or semi-automated |

| Seal Strength | Strong, consistent adhesion | Variable, depends on glue type and application |

| Cost | Moderate, cost-effective for high volumes | Lower material cost but higher labor cost |

| Durability | Resistant to moisture and temperature changes | Less durable, susceptible to environmental factors |

| Environmental Impact | Often recyclable, depends on tape material | May use solvent-based adhesives, less eco-friendly |

| Ease of Use | Simple application, less mess | Requires skill and precision |

| Common Uses | Shipping boxes, packaging sealing | Carton sealing, product assembly |

Introduction to Packaging Closures

Tape closure offers a secure, reusable option for packaging that enhances efficiency in sealing cartons and boxes, making it ideal for heavy-duty shipments. Glue closure provides a strong, permanent seal suited for tamper-evident and long-term storage applications, often used in retail packaging. Selecting between tape and glue closures depends on factors such as package weight, handling requirements, and the desired level of security.

What is Tape Closure?

Tape closure refers to a packaging method that uses adhesive tape strips to seal boxes or cartons, providing a secure and easy-to-apply solution for sealing packages. This method offers quick application, strong hold, and allows for easy inspection or reopening without damaging the container. Tape closures are widely used in logistics, shipping, and retail industries due to their versatility and reliability in maintaining package integrity during transit.

What is Glue Closure?

Glue closure is a packaging method where adhesive substances securely seal containers or boxes, ensuring product integrity and tamper evidence. It offers strong, durable bonds suitable for various materials such as cardboard, plastic, and paper, enhancing protection during shipping and handling. This closure type improves efficiency in automated packaging lines and supports branding through customized adhesive patterns.

Materials Used in Tape and Glue Closures

Tape closures commonly use materials like polypropylene, polyester, and paper, combined with different adhesive types such as acrylic or rubber-based glues to ensure strong bonding and ease of application. Glue closures typically involve cyanoacrylate or polyurethane-based adhesives applied to substrates like cardboard or plastic films, designed for permanent sealing and resistance to environmental factors. The choice of materials in both tape and glue closures significantly impacts their durability, flexibility, and suitability for specific packaging or sealing requirements.

Strength and Durability Comparison

Tape closures provide consistent shear and tensile strength, making them ideal for heavy-duty packaging and ensuring long-term durability under stress. Glue closures offer excellent initial adhesion but can weaken over time due to environmental factors like humidity and temperature fluctuations. For applications demanding high strength and prolonged durability, tape closures generally outperform glue closures in maintaining package integrity.

Application Speed and Efficiency

Tape closures offer rapid application speed due to their pre-cut design, enabling faster sealing in high-volume packaging lines compared to glue closures. The instant adhesion of tape eliminates drying or curing time, significantly enhancing operational efficiency and reducing downtime. Glue closures require precise application and curing periods, which can slow production and increase labor costs in time-sensitive environments.

Cost Analysis: Tape vs Glue Closure

Tape closure typically incurs higher upfront material costs but reduces labor expenses due to faster application and ease of use, making it cost-effective for high-volume operations. Glue closure generally has lower material costs but requires more labor time and specialized equipment for precise application, potentially increasing overall expenses. Your choice should balance these factors based on production volume, labor rates, and equipment availability to optimize cost efficiency.

Environmental Impact and Sustainability

Tape closure typically generates more plastic waste compared to glue closure, which often uses biodegradable adhesives that reduce environmental footprint. Glue closure systems can optimize packaging efficiency by using less material overall, contributing to lower carbon emissions during production and disposal. Sustainable packaging strategies increasingly favor glue closures for their potential to enhance recyclability and minimize landfill contribution.

Suitability for Different Packaging Types

Tape closure offers excellent suitability for heavy-duty and irregularly shaped packaging due to its strong adhesion and flexibility, ensuring secure sealing on corrugated boxes and cartons. Glue closure suits lightweight or uniform packages, providing a clean and tamper-evident seal ideal for paper envelopes and small retail boxes. Your choice depends on package size, weight, and material to ensure optimal protection and efficiency in sealing.

Conclusion: Choosing the Best Closure Method

Tape closure offers quick application and clean removal, enhancing packaging efficiency and reducing labor costs. Glue closure provides a more secure, tamper-evident seal suitable for heavy or irregular shipments, improving product protection during transit. Selecting the best closure method depends on factors such as package weight, handling requirements, security needs, and overall cost-effectiveness for the supply chain.

Tape closure vs glue closure Infographic

libmatt.com

libmatt.com