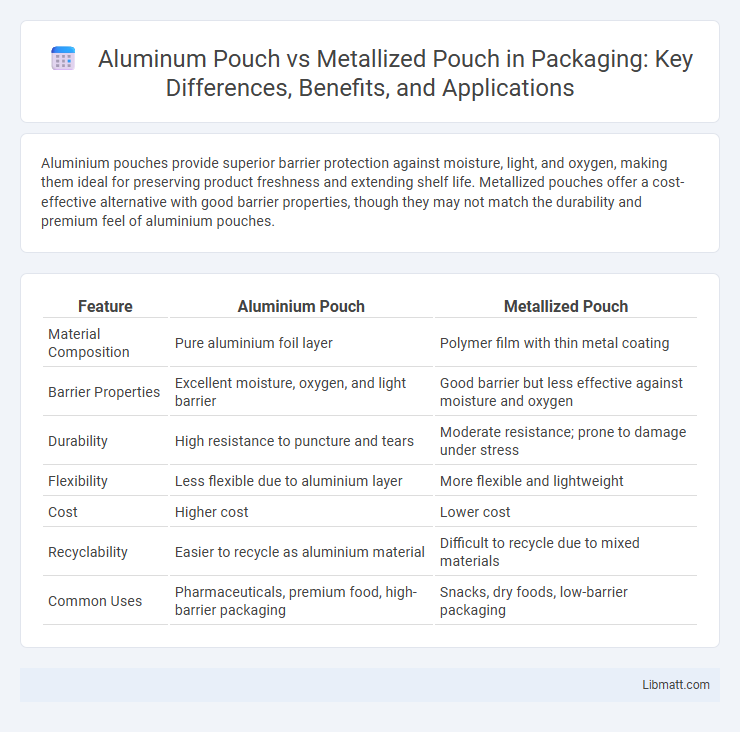

Aluminium pouches provide superior barrier protection against moisture, light, and oxygen, making them ideal for preserving product freshness and extending shelf life. Metallized pouches offer a cost-effective alternative with good barrier properties, though they may not match the durability and premium feel of aluminium pouches.

Table of Comparison

| Feature | Aluminium Pouch | Metallized Pouch |

|---|---|---|

| Material Composition | Pure aluminium foil layer | Polymer film with thin metal coating |

| Barrier Properties | Excellent moisture, oxygen, and light barrier | Good barrier but less effective against moisture and oxygen |

| Durability | High resistance to puncture and tears | Moderate resistance; prone to damage under stress |

| Flexibility | Less flexible due to aluminium layer | More flexible and lightweight |

| Cost | Higher cost | Lower cost |

| Recyclability | Easier to recycle as aluminium material | Difficult to recycle due to mixed materials |

| Common Uses | Pharmaceuticals, premium food, high-barrier packaging | Snacks, dry foods, low-barrier packaging |

Introduction to Aluminium and Metallized Pouches

Aluminium pouches consist of multiple layers of aluminium foil that provide excellent barrier properties against moisture, oxygen, and light, ensuring extended shelf life for products. Metallized pouches feature a plastic film coated with a thin layer of metal, usually aluminum, which offers cost-effective protection while maintaining flexibility and clarity. Both types are widely used in food packaging, with aluminium pouches offering superior barrier strength and metallized pouches balancing performance with affordability.

Material Composition and Structure

Aluminium pouches are made from pure aluminum foil, providing a single-layer barrier with excellent resistance to moisture, oxygen, and light, ensuring superior product preservation. Metallized pouches consist of a plastic film base coated with a thin layer of metal, usually aluminum, which offers flexibility and moderate barrier protection at a lower cost than pure aluminum. Your choice between these materials should consider the specific barrier requirements and cost constraints of your packaging needs.

Barrier Properties: Moisture, Oxygen, and Light Protection

Aluminium pouches offer superior barrier properties against moisture, oxygen, and light due to their continuous metal foil layer, ensuring optimal product freshness and shelf life. Metallized pouches provide good protection by coating plastic films with a thin metal layer, but they exhibit slightly lower moisture and oxygen resistance compared to pure aluminium foil. For high-barrier packaging needs requiring maximum protection against environmental factors, aluminium pouches remain the preferred choice over metallized alternatives.

Weight and Flexibility Comparison

Aluminium pouches generally weigh more than metallized pouches due to the thicker metal layer, impacting transport costs and handling. Metallized pouches offer superior flexibility because their thinner metal coating allows for easier shaping and sealing without compromising durability. These factors make metallized pouches more suitable for lightweight, flexible packaging applications, while aluminium pouches excel in barrier protection but add extra weight.

Printing and Branding Capabilities

Aluminium pouches offer superior printing quality with vibrant colors and crisp details due to their smooth, non-porous surface, enhancing brand visibility and appeal. Metallized pouches provide a reflective, shiny finish but may have limitations in achieving fine print detail and full-color vibrancy compared to aluminium. Brands seeking high-impact graphics and precise logos often prefer aluminium pouches for premium appearance and effective marketing.

Cost Analysis and Economic Considerations

Aluminium pouches generally incur higher raw material costs due to the use of pure aluminium foil, leading to increased production expenses compared to metallized pouches, which utilize a thin plastic film coated with metal, reducing material expenditure. Metallized pouches offer a cost-effective alternative with adequate barrier properties for many applications, making them economically advantageous for large-scale packaging where budget constraints are critical. The choice between aluminium and metallized pouches hinges on balancing upfront material costs against specific product protection requirements and potential long-term savings through shelf-life extension or reduced product waste.

Environmental Impact and Recyclability

Aluminium pouches offer excellent recyclability due to the widespread availability of aluminium recycling facilities, reducing environmental impact by enabling material recovery and reuse. Metallized pouches, often composed of mixed materials such as plastic films and metal layers, present significant challenges in recycling processes, leading to increased waste and lower environmental sustainability. Your choice of packaging can greatly influence waste management efficiency and the overall carbon footprint of the product lifecycle.

Common Applications in Various Industries

Aluminium pouches are widely used in the pharmaceutical, food, and cosmetic industries due to their excellent barrier properties against moisture, oxygen, and light, ensuring product freshness and extended shelf life. Metallized pouches find common applications in snack food packaging, pet food, and coffee industries, offering cost-effective protection and appealing glossy finishes for retail display. Both packaging types are favored for flexible, lightweight, and durable solutions in diverse industrial sectors.

Performance in Shelf Life Extension

Aluminium pouches offer superior barrier properties against moisture, oxygen, and light, significantly extending the shelf life of perishable products compared to metallized pouches. Metallized pouches provide good protection but are less effective in preserving product freshness over long periods due to their lower resistance to environmental factors. Your choice of packaging directly impacts product longevity, with aluminium pouches generally ensuring the highest performance in shelf life extension.

Choosing the Right Pouch for Your Product

Aluminium pouches offer superior barrier properties against moisture, oxygen, and light, making them ideal for products requiring extended shelf life and protection from external contaminants. Metallized pouches provide a cost-effective alternative with good barrier performance, suitable for less sensitive items or short-term packaging needs. Selecting the right pouch depends on factors such as product sensitivity, shelf life requirements, and budget constraints, ensuring optimal preservation and cost-efficiency.

Aluminium pouch vs metallized pouch Infographic

libmatt.com

libmatt.com