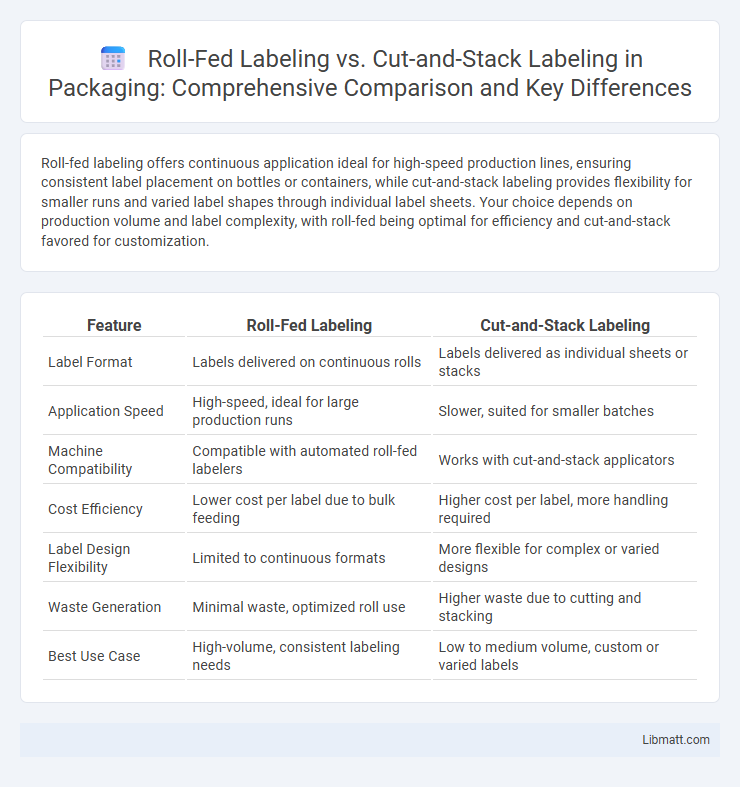

Roll-fed labeling offers continuous application ideal for high-speed production lines, ensuring consistent label placement on bottles or containers, while cut-and-stack labeling provides flexibility for smaller runs and varied label shapes through individual label sheets. Your choice depends on production volume and label complexity, with roll-fed being optimal for efficiency and cut-and-stack favored for customization.

Table of Comparison

| Feature | Roll-Fed Labeling | Cut-and-Stack Labeling |

|---|---|---|

| Label Format | Labels delivered on continuous rolls | Labels delivered as individual sheets or stacks |

| Application Speed | High-speed, ideal for large production runs | Slower, suited for smaller batches |

| Machine Compatibility | Compatible with automated roll-fed labelers | Works with cut-and-stack applicators |

| Cost Efficiency | Lower cost per label due to bulk feeding | Higher cost per label, more handling required |

| Label Design Flexibility | Limited to continuous formats | More flexible for complex or varied designs |

| Waste Generation | Minimal waste, optimized roll use | Higher waste due to cutting and stacking |

| Best Use Case | High-volume, consistent labeling needs | Low to medium volume, custom or varied labels |

Introduction to Roll-Fed and Cut-and-Stack Labeling

Roll-fed labeling uses continuous rolls of labels that are fed into labeling machines for high-speed, automated application, ideal for large production runs requiring consistent label placement. Cut-and-stack labeling involves separate sheets of pre-cut labels stacked for individual application, which suits smaller batches or custom labeling needs with variable designs. You can choose between these methods based on production volume, label complexity, and machine compatibility to optimize efficiency.

Overview of Labeling Technologies

Roll-fed labeling uses continuous rolls of labels applied by machines at high speeds, making it ideal for large-scale production with consistent label placement. Cut-and-stack labeling involves individual labels cut and stacked before application, offering precision and flexibility for small batches or custom designs. Your choice depends on production volume, label complexity, and workflow efficiency requirements.

How Roll-Fed Labeling Works

Roll-fed labeling operates by continuously unwinding labels from a large roll, feeding them through a labeling machine that applies each label precisely onto products at high speed. The system ensures consistent label alignment and registration, making it ideal for high-volume packaging lines seeking efficiency and accuracy. Your production process benefits from reduced downtime and smoother integration with automated assembly, enhancing overall throughput.

How Cut-and-Stack Labeling Works

Cut-and-stack labeling involves printing labels on large sheets of material that are subsequently cut into individual labels and stacked for easy handling. This method allows high-resolution printing and versatility in label shapes and sizes, making it suitable for complex designs and smaller production runs. The stacked labels are then fed manually or automatically into labeling machines, enabling precise placement on products.

Material Types Used in Roll-Fed vs Cut-and-Stack

Roll-fed labeling predominantly uses flexible materials like films, papers, and laminates designed for continuous application processes, ensuring high-speed and consistent output. Cut-and-stack labeling typically employs rigid or thicker substrates such as cardstock, textured papers, and specialty films suited for smaller runs or unique label shapes. The choice of material impacts print quality, adhesive compatibility, and the overall durability of the label in each labeling method.

Speed and Efficiency Comparison

Roll-fed labeling systems excel in speed and efficiency by continuously applying labels from large rolls, minimizing downtime for reel changes and allowing for faster production rates. Cut-and-stack labeling operates with pre-cut labels arranged on sheets, requiring more frequent stops to reload and align, which can reduce overall throughput. Your choice between the two methods should consider the balance between label size, production speed, and operational efficiency to optimize labeling performance.

Cost Analysis: Roll-Fed vs Cut-and-Stack

Roll-fed labeling typically offers lower per-unit costs due to higher production speeds and less material waste compared to cut-and-stack labeling, which involves additional cutting and handling steps that increase labor and equipment expenses. The continuous feed mechanism in roll-fed systems reduces setup time and downtime, enhancing overall efficiency for high-volume runs. Cut-and-stack labeling incurs higher costs in small-batch or variable label runs due to slower processing and increased manual intervention.

Applicability for Different Packaging Shapes and Sizes

Roll-fed labeling excels in high-speed applications and is ideal for uniform containers such as bottles and cans, offering consistent label placement on cylindrical and slightly tapered shapes. Cut-and-stack labeling provides greater flexibility for irregularly shaped or flat containers, handling a wider variety of sizes and shapes including jars, boxes, and cartons with precision. Your choice depends on packaging diversity; roll-fed suits streamlined production lines, while cut-and-stack adapts better to varied product shapes and sizes.

Sustainability and Waste Considerations

Roll-fed labeling minimizes adhesive waste and reduces packaging material consumption compared to cut-and-stack labeling, which often generates excess die-cut label waste. The continuous feed process in roll-fed systems enhances efficiency, leading to lower energy usage and less material scrap. Brands prioritizing sustainability favor roll-fed labeling to achieve a smaller environmental footprint and improved resource optimization.

Choosing the Right Labeling System for Your Needs

Roll-fed labeling offers high-speed application ideal for continuous production lines, while cut-and-stack labeling provides versatility for smaller runs and diverse label shapes. Your choice depends on factors such as production volume, label size, and material type. Evaluating these parameters ensures you select a labeling system that maximizes efficiency and meets your specific packaging requirements.

Roll-fed labeling vs cut-and-stack labeling Infographic

libmatt.com

libmatt.com