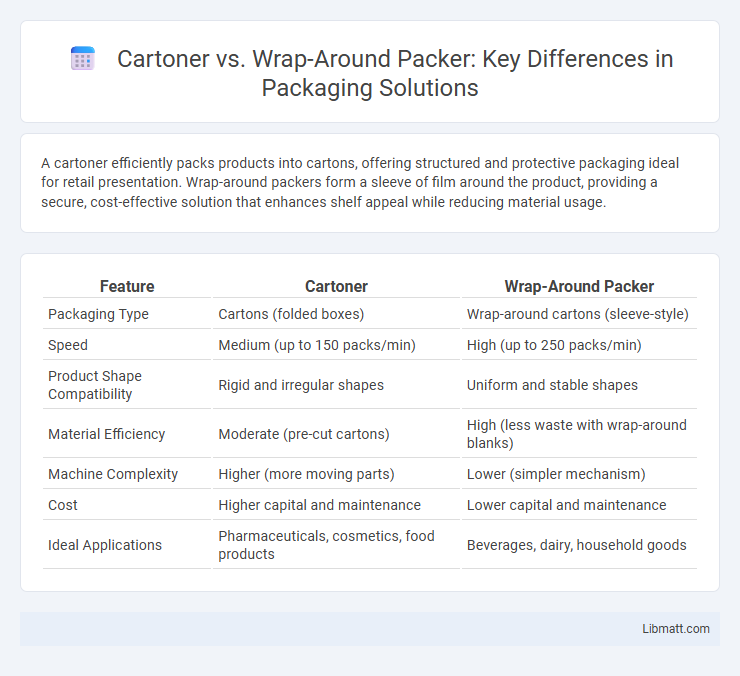

A cartoner efficiently packs products into cartons, offering structured and protective packaging ideal for retail presentation. Wrap-around packers form a sleeve of film around the product, providing a secure, cost-effective solution that enhances shelf appeal while reducing material usage.

Table of Comparison

| Feature | Cartoner | Wrap-Around Packer |

|---|---|---|

| Packaging Type | Cartons (folded boxes) | Wrap-around cartons (sleeve-style) |

| Speed | Medium (up to 150 packs/min) | High (up to 250 packs/min) |

| Product Shape Compatibility | Rigid and irregular shapes | Uniform and stable shapes |

| Material Efficiency | Moderate (pre-cut cartons) | High (less waste with wrap-around blanks) |

| Machine Complexity | Higher (more moving parts) | Lower (simpler mechanism) |

| Cost | Higher capital and maintenance | Lower capital and maintenance |

| Ideal Applications | Pharmaceuticals, cosmetics, food products | Beverages, dairy, household goods |

Introduction to Cartoner and Wrap-Around Packer

Cartoners and wrap-around packers are essential packaging machines used in various industries to enhance product presentation and protection. Cartoners automate the process of erecting cartons, loading products, and closing cartons, ideal for single or grouped items requiring rigid packaging. Wrap-around packers create secure, tamper-evident packaging by wrapping a flexible film or board around a product, offering superior product visibility and efficient material usage for your packaging needs.

Understanding Cartoners: Definition and Function

Cartoners automate the process of placing products into cartons, enhancing packaging speed and consistency in various industries such as food and pharmaceuticals. These machines handle folding, loading, and sealing of cartons, ensuring product protection and professional presentation. Specialized cartoners are designed to accommodate different carton styles, including tuck-end and crash-lock types, optimizing packaging efficiency.

How Wrap-Around Packers Operate

Wrap-around packers operate by forming a continuous sleeve of packaging material that wraps around the product and is sealed at the edges to create a secure, compact package. Unlike traditional cartoners, which erect pre-formed cartons and insert products manually or automatically, wrap-around packers streamline the packaging process by integrating product feeding, wrap formation, and sealing in a single automated system. Your production line benefits from increased speed and reduced material waste, making wrap-around packers ideal for high-volume applications.

Key Differences Between Cartoners and Wrap-Around Packers

Cartoners use mechanical arms to place products into pre-made cartons, offering precise, high-speed packaging ideal for delicate items. Wrap-around packers form a continuous cardboard sleeve around products, providing efficient, cost-effective packaging with minimal material waste. Your choice depends on product fragility, packaging speed, and budget considerations.

Packaging Formats: Cartoning vs. Wrap-Around Solutions

Cartoner machines deliver versatile packaging formats ideal for multipacks, individual product boxing, and display-ready cartons, enabling organized, protective, and visually appealing presentation. Wrap-around packers use flexible film to securely encase products, offering a cost-effective, space-efficient solution that enhances product visibility while minimizing material waste. Your choice depends on the product's protection needs and shelf presentation, with cartoning excelling in premium, rigid packaging and wrap-around packing optimizing speed and sustainability.

Speed and Throughput Comparison

Wrap-around packers typically achieve higher speeds and throughput than cartoners due to their more continuous wrapping process, often reaching up to 200+ packs per minute compared to cartoners averaging 60-120 packs per minute. Cartoners involve more complex mechanical operations, such as erecting cartons and inserting products, which can slow down the packaging line. Industries requiring rapid flow and minimal changeover times favor wrap-around packers to maximize output efficiency in high-volume production settings.

Flexibility and Adaptability in Packaging Lines

Cartoners offer greater flexibility in handling diverse product shapes and sizes, making them ideal for packaging irregular or delicate items. Wrap-around packers excel in high-speed operations with consistent product dimensions, providing efficient and precise packaging for uniform items. Choosing between the two depends on production requirements, with cartoners suited for versatility and wrap-around packers optimized for speed and cost-effectiveness.

Cost Efficiency: Initial Investment and Maintenance

Cartoners typically require a lower initial investment compared to wrap-around packers, making them more accessible for small to medium-sized operations. Maintenance costs for cartoners are generally higher due to the mechanical complexity and frequent adjustments needed for carton alignment and sealing. Your choice depends on balancing upfront capital with ongoing maintenance expenses to optimize cost efficiency for your packaging line.

Application Scenarios: When to Use Each System

Cartoners are ideal for packaging individual products such as cosmetics, pharmaceuticals, and small food items that require precise product placement within a box for enhanced presentation and protection. Wrap-around packers excel in high-speed environments where products like bottles, cans, and cartons need efficient, secure primary or secondary packaging with minimal material waste. Your choice depends on product type, packaging speed requirements, and the need for customization versus automation efficiency.

Choosing the Right Packaging Machine for Your Business

Selecting between a cartoner and a wrap-around packer depends on your product type, production speed, and packaging style preferences. Cartoners are ideal for neatly enclosing individual products in cartons, offering precise presentation and protection for items like pharmaceuticals and cosmetics. Wrap-around packers provide efficient, continuous packaging with minimal material usage, making them suitable for high-volume operations requiring secure, tight packaging for products such as beverages and consumer goods.

Cartoner vs wrap-around packer Infographic

libmatt.com

libmatt.com