Dust flaps protect your vehicle's undercarriage from dirt, mud, and debris by blocking particles from passing through gaps, ensuring cleaner and safer driving conditions. Crash lock bases enhance impact resistance and structural integrity during collisions, reducing damage by absorbing and distributing collision forces effectively.

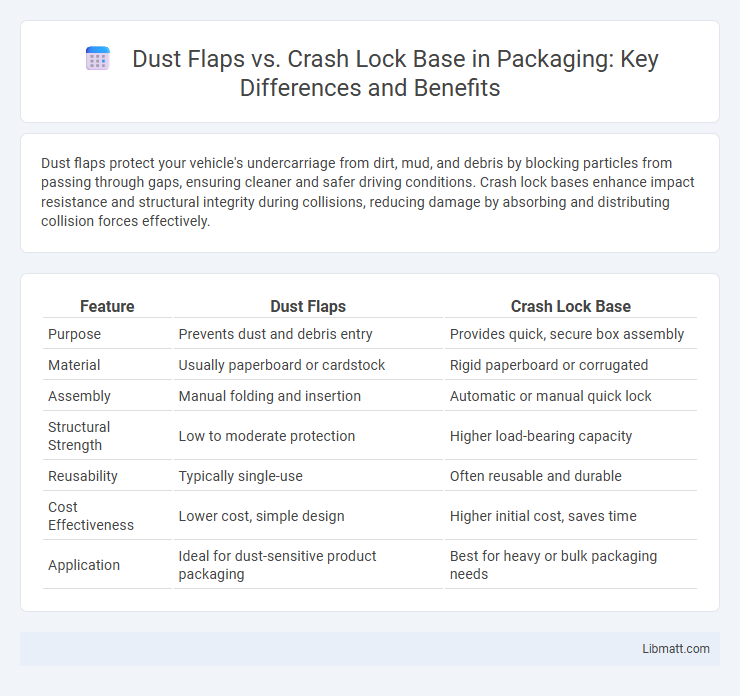

Table of Comparison

| Feature | Dust Flaps | Crash Lock Base |

|---|---|---|

| Purpose | Prevents dust and debris entry | Provides quick, secure box assembly |

| Material | Usually paperboard or cardstock | Rigid paperboard or corrugated |

| Assembly | Manual folding and insertion | Automatic or manual quick lock |

| Structural Strength | Low to moderate protection | Higher load-bearing capacity |

| Reusability | Typically single-use | Often reusable and durable |

| Cost Effectiveness | Lower cost, simple design | Higher initial cost, saves time |

| Application | Ideal for dust-sensitive product packaging | Best for heavy or bulk packaging needs |

Introduction to Dust Flaps and Crash Lock Base

Dust flaps protect vehicle components by preventing dirt, mud, and debris from accumulating, effectively extending the lifespan of your vehicle's undercarriage. Crash lock bases provide enhanced safety by securely mounting parts with a locking mechanism designed to absorb impacts and minimize damage during collisions. Understanding the functional differences between dust flaps and crash lock bases helps in selecting the right protection solution for your vehicle.

What Are Dust Flaps?

Dust flaps are flexible panels attached to the lower edges of vehicles, designed to prevent dirt, mud, and debris from being thrown into the air by the rotating tires. Typically made from durable rubber or plastic materials, they help protect the vehicle's body and other cars on the road from damage caused by flying particles. Dust flaps effectively reduce maintenance costs and enhance driving safety by minimizing road spray and debris.

What Is a Crash Lock Base?

A crash lock base is a type of mounting system commonly used for securing dust flaps on trucks and trailers, designed to provide a durable and stable attachment point. It consists of interlocking components that snap together, allowing for quick installation and removal while ensuring the flap remains firmly in place during heavy use or impact. Your choice between dust flaps with a crash lock base versus other mounting options depends on the need for ease of maintenance and reliable performance in demanding environments.

Key Differences Between Dust Flaps and Crash Lock Base

Dust flaps are flexible panels attached to the wheel wells of vehicles to prevent dirt, debris, and moisture from being thrown onto the carriage or surrounding vehicles, enhancing cleanliness and safety. Crash lock bases are structural components designed to absorb and dissipate energy during collisions, improving vehicle safety by minimizing damage and protecting occupants. The key difference lies in their primary function: dust flaps serve as protective barriers against environmental elements, while crash lock bases provide impact resistance and structural integrity during crashes.

Structural Design and Engineering Comparison

Dust flaps feature flexible rubber or polymer materials designed primarily to prevent debris from being flung by vehicle tires, relying on simple mounting brackets for easy installation and minimal structural load. Crash lock bases incorporate reinforced steel or heavy-duty materials engineered to absorb and distribute impact forces, enhancing durability and vehicle protection through integrated locking mechanisms that secure the mudguard assembly firmly to the chassis. The structural design of dust flaps prioritizes flexibility and lightweight characteristics, whereas crash lock bases focus on robust engineering solutions aimed at maximizing impact resistance and long-term structural integrity.

Assembly Time and Efficiency: Dust Flaps vs Crash Lock Base

Dust flaps offer quicker assembly times due to their simple fold-and-attach design, reducing labor costs and increasing production efficiency. Crash lock bases require more precise folding and locking mechanisms, which can extend assembly time but provide a sturdier, more secure package foundation. Choosing dust flaps enhances speed in high-volume operations, while crash lock bases prioritize durability at a slight efficiency trade-off.

Cost Implications of Each Option

Dust flaps generally incur lower initial costs, as they are simpler to manufacture and install compared to crash lock bases. Crash lock bases, while costlier upfront due to their robust materials and secure locking mechanisms, offer greater durability and reduced long-term maintenance expenses. Evaluating total cost of ownership between the two options highlights the trade-off between immediate affordability and long-term investment.

Durability and Strength Considerations

Dust flaps are typically made from flexible rubber or plastic materials, providing moderate durability and effective protection against dirt and debris, but they may wear out faster under harsh conditions. Crash lock bases, constructed from heavy-duty metal or reinforced composites, offer superior strength and enhanced resistance to impact and environmental stress, ensuring longer-lasting performance in demanding applications. Choosing between the two depends on the required balance of flexibility and structural integrity for specific vehicle or equipment use cases.

Best Use Cases for Dust Flaps and Crash Lock Base

Dust flaps excel in environments with heavy debris, mud, or snow, providing optimal protection for your vehicle's undercarriage and preventing dirt buildup on tires and body panels. Crash lock bases are ideal for vehicles frequently exposed to rough terrain or impacts, as they offer enhanced stability and durability by securely locking the mud flaps in place, reducing wear and tear. Choosing between these depends on your driving conditions: dust flaps suit everyday use on paved roads with occasional dirt, while crash lock bases are better for off-road or high-impact settings.

Choosing the Optimal Box Solution for Your Packaging Needs

Dust flaps offer a cost-effective, easy-to-assemble option for protecting contents from dirt and debris, ideal for lightweight and less fragile items. Crash lock base boxes provide superior strength and durability, featuring a pre-glued, collapsible bottom that ensures quick setup and enhanced load-bearing capacity for heavier or fragile products. Selecting between dust flaps and crash lock base depends on product weight, protection requirements, and assembly efficiency to optimize packaging performance and cost-effectiveness.

Dust flaps vs crash lock base Infographic

libmatt.com

libmatt.com