Chipboard is made from wood chips bonded with resin under heat and pressure, offering a cost-effective and lightweight option mainly used in furniture cores and packaging. Fiberboard, produced by breaking down wood fibers and compressing them, provides a smoother surface and greater density, making it ideal for cabinetry, paneling, and decorative projects where a refined finish is essential.

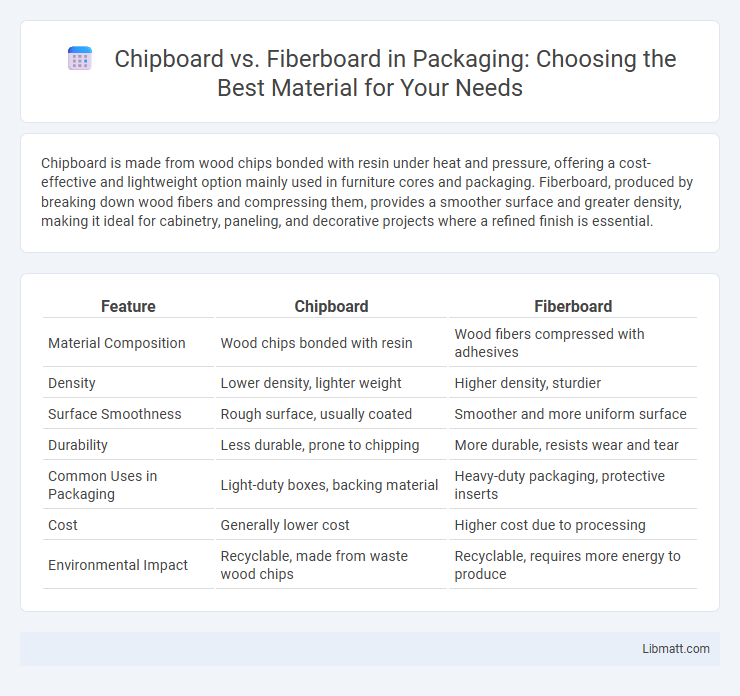

Table of Comparison

| Feature | Chipboard | Fiberboard |

|---|---|---|

| Material Composition | Wood chips bonded with resin | Wood fibers compressed with adhesives |

| Density | Lower density, lighter weight | Higher density, sturdier |

| Surface Smoothness | Rough surface, usually coated | Smoother and more uniform surface |

| Durability | Less durable, prone to chipping | More durable, resists wear and tear |

| Common Uses in Packaging | Light-duty boxes, backing material | Heavy-duty packaging, protective inserts |

| Cost | Generally lower cost | Higher cost due to processing |

| Environmental Impact | Recyclable, made from waste wood chips | Recyclable, requires more energy to produce |

Introduction to Chipboard and Fiberboard

Chipboard, also known as particleboard, is an engineered wood product made from wood chips, sawdust, and resin, offering affordability and versatility in furniture and construction. Fiberboard, including medium-density fiberboard (MDF) and high-density fiberboard (HDF), is manufactured from wood fibers bonded under heat and pressure, providing a smoother surface and greater strength. Understanding the differences in composition and properties helps you choose the right material for your specific project needs.

Composition and Manufacturing Processes

Chipboard is primarily made from wood chips, sawmill shavings, and resin, compressed under heat to form dense sheets. Fiberboard, especially medium-density fiberboard (MDF), uses wood fibers combined with wax and resin, pressed at high temperature and pressure for a smoother, more uniform surface. The manufacturing of chipboard emphasizes particle size and bonding agents, while fiberboard production focuses on fiber refinement and achieving consistent density.

Physical Properties and Appearance

Chipboard is composed of wood particles bonded with resin, resulting in a coarse texture and uneven surface, often covered with a laminate or veneer for enhanced appearance. Fiberboard, particularly medium-density fiberboard (MDF), consists of finely ground wood fibers compressed into a smooth, uniform sheet, providing a consistent surface ideal for painting and finishing. The denser fiberboard offers superior strength and a more refined look compared to the rougher, less durable chipboard.

Strength and Durability Comparison

Chipboard, made from wood chips and resin, offers moderate strength but is less durable compared to fiberboard, which is manufactured from wood fibers compressed under high heat and pressure. Fiberboard, especially medium-density fiberboard (MDF), provides superior density and resistance to warping, making it ideal for furniture and cabinetry requiring long-term structural integrity. While chipboard is cost-effective and suitable for lightweight applications, fiberboard's enhanced durability supports heavier loads and better withstands moisture and impact.

Cost Differences

Chipboard generally costs less than fiberboard due to its lower manufacturing complexity and use of larger wood particles, making it an economical choice for budget-conscious projects. Fiberboard, particularly medium-density fiberboard (MDF), involves finer wood fibers and heat pressing, resulting in higher production costs and a price premium. The price gap between chipboard and fiberboard varies by thickness and density, with fiberboard offering better durability and surface finish that justifies its higher investment for quality applications.

Environmental Impact and Sustainability

Chipboard and fiberboard differ notably in environmental impact and sustainability; chipboard is often manufactured using recycled wood chips and sawdust, reducing waste and the need for virgin timber. Fiberboard, especially medium-density fiberboard (MDF), typically involves a more energy-intensive production process and may include synthetic resins that emit formaldehyde, raising concerns about indoor air quality. Choosing certified sustainable sources and low-emission adhesives enhances the eco-friendliness of both materials in construction and furniture applications.

Common Uses and Applications

Chipboard is widely used in furniture manufacturing, cabinetry, and flooring underlayment due to its cost-effectiveness and structural strength. Fiberboard, particularly medium-density fiberboard (MDF), is favored for detailed millwork, speaker cabinets, and interior paneling because of its smooth surface and uniform density. Both materials serve in construction and woodworking but are chosen based on specific requirements such as durability, finish quality, and environmental resistance.

Installation and Workability

Chipboard offers ease of installation due to its lightweight nature and compatibility with common fasteners, making it ideal for quick assembly in furniture and cabinetry. Fiberboard, particularly medium-density fiberboard (MDF), provides superior workability with smooth surfaces that hold paint and veneers well, allowing for intricate cutting and shaping without splintering. Both materials require pre-drilling for screws to prevent splitting, but fiberboard demands more careful handling due to its denser composition and potential for dust during machining.

Moisture Resistance and Longevity

Chipboard exhibits lower moisture resistance compared to fiberboard, as its composition of wood particles bound with adhesive tends to absorb water, leading to swelling and reduced durability in humid conditions. Fiberboard, especially medium-density fiberboard (MDF) and high-density fiberboard (HDF), incorporates finer wood fibers and resins that enhance moisture resistance, making it more suitable for environments with fluctuating humidity. The increased density and uniform structure of fiberboard contribute to superior longevity, maintaining structural integrity longer than chipboard when exposed to moisture.

Choosing the Right Material for Your Project

Chipboard offers cost-effective durability and is ideal for structural applications like shelving and furniture bases, while fiberboard provides a smoother surface perfect for detailed painting and cabinetry. Your project's requirements for strength, finish, and moisture resistance determine which material suits best. Opt for chipboard when budget and load-bearing capacity are priorities, and choose fiberboard for refined aesthetics and ease of machining.

Chipboard vs fiberboard Infographic

libmatt.com

libmatt.com