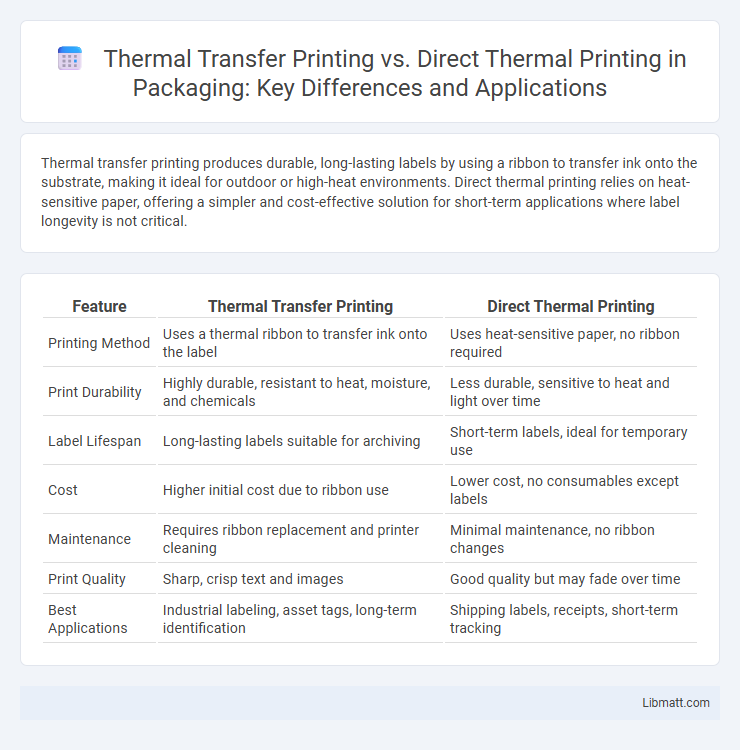

Thermal transfer printing produces durable, long-lasting labels by using a ribbon to transfer ink onto the substrate, making it ideal for outdoor or high-heat environments. Direct thermal printing relies on heat-sensitive paper, offering a simpler and cost-effective solution for short-term applications where label longevity is not critical.

Table of Comparison

| Feature | Thermal Transfer Printing | Direct Thermal Printing |

|---|---|---|

| Printing Method | Uses a thermal ribbon to transfer ink onto the label | Uses heat-sensitive paper, no ribbon required |

| Print Durability | Highly durable, resistant to heat, moisture, and chemicals | Less durable, sensitive to heat and light over time |

| Label Lifespan | Long-lasting labels suitable for archiving | Short-term labels, ideal for temporary use |

| Cost | Higher initial cost due to ribbon use | Lower cost, no consumables except labels |

| Maintenance | Requires ribbon replacement and printer cleaning | Minimal maintenance, no ribbon changes |

| Print Quality | Sharp, crisp text and images | Good quality but may fade over time |

| Best Applications | Industrial labeling, asset tags, long-term identification | Shipping labels, receipts, short-term tracking |

Introduction to Thermal Printing Technologies

Thermal transfer printing uses a heated ribbon to transfer ink onto labels or substrates, providing durable, high-resolution prints ideal for long-lasting applications. Direct thermal printing employs heat-sensitive paper that darkens when heated, eliminating the need for ribbons but producing prints susceptible to fading and heat damage. Both technologies are widely used in barcode labeling, shipping, and retail industries, with the choice depending on durability requirements and environmental conditions.

How Thermal Transfer Printing Works

Thermal transfer printing utilizes a heated printhead to transfer ink from a ribbon onto the printing surface, producing durable, high-quality images ideal for long-lasting labels and barcodes. The process involves melting wax or resin-based ink on the ribbon that adheres to various materials such as paper, polyester, or polypropylene. This method ensures resistance to heat, moisture, and chemicals, making it suitable for industrial applications requiring longevity and clarity.

How Direct Thermal Printing Works

Direct thermal printing uses heat-sensitive paper that darkens when exposed to a thermal printhead, creating images without the need for ribbons or ink. This method relies on chemically treated paper that reacts instantly to heat, making it ideal for short-term labels like shipping labels and receipts. The simplicity and cost-effectiveness of direct thermal printers make them popular in retail, logistics, and healthcare industries.

Key Differences Between Thermal Transfer and Direct Thermal Printing

Thermal transfer printing uses a ribbon coated with ink that melts onto the label, providing durable and long-lasting prints suitable for outdoor or industrial use, while direct thermal printing relies on heat-sensitive paper that darkens when heated, ideal for short-term labeling like receipts. Thermal transfer prints resist fading, scratching, and chemicals, whereas direct thermal prints may fade over time, especially when exposed to heat or light. Your choice depends on the label's intended lifespan and environmental exposure, with thermal transfer preferred for durability and direct thermal for cost-effective, temporary applications.

Print Quality Comparison

Thermal transfer printing delivers higher print quality with sharper, more durable images due to its use of ribbon-coated ink that resists smudging and fading, making it ideal for long-term labeling. Direct thermal printing produces images by heating specially coated thermal paper, resulting in prints that may fade over time and are less resistant to heat and light exposure. The choice between the two depends on required print longevity and environmental durability, with thermal transfer favored for high-resolution and archival-quality labels.

Durability and Longevity of Printed Labels

Thermal transfer printing produces labels with superior durability and longevity, making them resistant to fading, smudging, and harsh environmental conditions, ideal for long-term applications. Direct thermal printing uses chemically treated paper that darkens when heated, resulting in labels that are less durable and prone to fading over time, especially when exposed to heat, light, or abrasion. When selecting a printing method, consider how long your labels need to last and the conditions they will face to ensure optimal readability and performance.

Cost Considerations and Consumables

Thermal transfer printing generally involves higher initial costs due to the need for ribbons, which increases ongoing consumable expenses compared to direct thermal printing that requires only heat-sensitive paper. Direct thermal printers have lower operating costs but may lead to frequent media replacements as thermal paper is less durable and more sensitive to environmental conditions. Businesses prioritizing long-lasting labels and images usually invest more upfront in thermal transfer technology to reduce total cost of ownership over time.

Suitable Applications for Each Printing Method

Thermal transfer printing excels in producing durable, long-lasting labels suitable for outdoor use, industrial environments, and product identification where resistance to heat, chemicals, and abrasion is essential. Direct thermal printing is ideal for short-term applications like shipping labels, receipts, and event tickets, where labels are not exposed to harsh conditions and longevity is not critical. Your choice depends on whether you need high durability or cost-effective, fast printing for temporary labels.

Environmental Impact and Sustainability

Thermal transfer printing uses ribbons that create waste and relies on consumables with plastic components, resulting in a higher environmental footprint compared to direct thermal printing, which uses heat-sensitive paper without ribbons and generates less waste. Direct thermal printing, however, involves paper that is often less durable and prone to fading, increasing the frequency of label replacement and overall paper consumption. Evaluating sustainability, thermal transfer printing tends to have longer-lasting prints reducing waste in certain applications, while direct thermal printing offers a simpler, ribbon-free process with lower immediate waste output but potentially higher paper usage over time.

Choosing the Right Printing Solution for Your Needs

Thermal transfer printing offers durability and resistance to fading, making it ideal for long-lasting labels and barcodes on a variety of materials. Direct thermal printing, while cost-effective and simple to operate, suits short-term applications where labels aren't exposed to heat or friction. Evaluating your label lifespan, material compatibility, and budget will help you choose the printing solution best aligned with your specific requirements.

Thermal transfer printing vs direct thermal printing Infographic

libmatt.com

libmatt.com