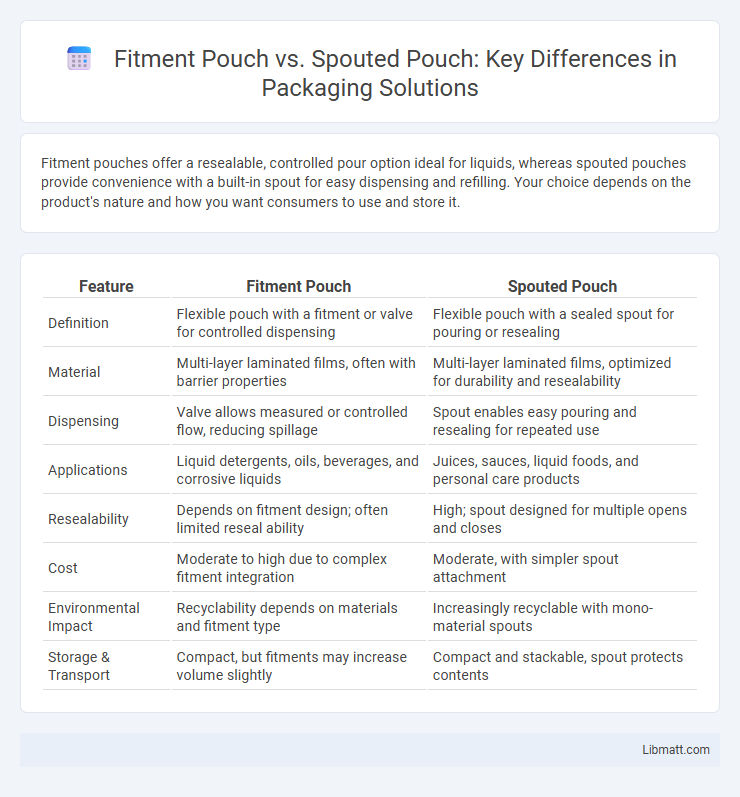

Fitment pouches offer a resealable, controlled pour option ideal for liquids, whereas spouted pouches provide convenience with a built-in spout for easy dispensing and refilling. Your choice depends on the product's nature and how you want consumers to use and store it.

Table of Comparison

| Feature | Fitment Pouch | Spouted Pouch |

|---|---|---|

| Definition | Flexible pouch with a fitment or valve for controlled dispensing | Flexible pouch with a sealed spout for pouring or resealing |

| Material | Multi-layer laminated films, often with barrier properties | Multi-layer laminated films, optimized for durability and resealability |

| Dispensing | Valve allows measured or controlled flow, reducing spillage | Spout enables easy pouring and resealing for repeated use |

| Applications | Liquid detergents, oils, beverages, and corrosive liquids | Juices, sauces, liquid foods, and personal care products |

| Resealability | Depends on fitment design; often limited reseal ability | High; spout designed for multiple opens and closes |

| Cost | Moderate to high due to complex fitment integration | Moderate, with simpler spout attachment |

| Environmental Impact | Recyclability depends on materials and fitment type | Increasingly recyclable with mono-material spouts |

| Storage & Transport | Compact, but fitments may increase volume slightly | Compact and stackable, spout protects contents |

Introduction to Fitment Pouches and Spouted Pouches

Fitment pouches feature a pre-installed fitment or valve that enhances dispensing control and resealability, making them ideal for liquid and semi-liquid products such as detergents and beverages. Spouted pouches incorporate a built-in spout for convenient pouring, commonly used in packaging liquids like juices, sauces, and oils. Both packaging types offer flexibility, reduced weight, and sustainability compared to rigid containers, catering to diverse consumer needs and product preservation.

Material Composition and Design Features

Fitment pouches are typically made from multi-layer laminates combining materials like PET, aluminum foil, and polyethylene to ensure durability and puncture resistance, featuring a rigid plastic fitment that facilitates easy pouring and resealing. Spouted pouches also use similar laminated films but incorporate a flexible spout attached directly to the pouch, optimizing lightweight packaging and convenience for liquids or semi-liquids. Both designs emphasize barrier properties and seal integrity, with fitment pouches offering enhanced structural support and spouted pouches focusing on spill prevention and user-friendly dispensing.

Manufacturing Processes Compared

Fitment pouches require the integration of a rigid or flexible fitment during the pouch forming stage, involving precise heat sealing and specialized equipment to attach valves or spouts securely. Spouted pouches are produced by first forming the pouch body via roll stock lamination and then heat sealing a spout to a pre-made opening, allowing for efficient filling and resealing capabilities. The manufacturing process for fitment pouches is generally more complex and cost-intensive due to the additional materials and assembly steps compared to the simpler, faster spouted pouch production.

Filling and Sealing Methods

Fitment pouches utilize pre-attached spouts that allow filling through specialized nozzles compatible with automated equipment, ensuring precise liquid dispensing and secure sealing via heat or ultrasonic methods around the fitment base. Spouted pouches are filled by inserting filling nozzles directly into the spout, facilitating efficient volumetric filling and sealed by heat sealing the spout cap to maintain product freshness and prevent leaks. Both pouch types require precise alignment during sealing to guarantee airtight closure and compatibility with high-speed filling lines.

Strength and Durability Differences

Fitment pouches typically offer enhanced strength due to the reinforced spout attachment, which minimizes leakage and withstands higher pressure during pouring. Spouted pouches, while convenient for controlled dispensing, may have weaker seals around the spout, making them less durable under rough handling or extended use. Materials used in fitment pouches are often thicker and designed to reinforce structural integrity, resulting in superior durability compared to standard spouted pouches.

Usage in Various Industries

Fitment pouches are widely utilized in the food and beverage industry for packaging liquids, sauces, and condiments, offering convenience and resealability. Spouted pouches find extensive application in personal care and household products, such as shampoos, detergents, and liquid soaps, due to their easy pouring and resealing features. Both packaging types enhance product preservation and user experience across pharmaceutical and agricultural sectors, adapting to the specific dispensing needs of each industry.

Consumer Convenience and Accessibility

Fitment pouches feature integrated spouts and caps, enhancing consumer convenience by allowing easy pouring and resealing, which reduces product spillage and waste. Spouted pouches offer accessibility benefits through their portable design and simple dispensing mechanism, making them ideal for on-the-go use and precise portion control. Your choice between these packaging options influences the ease of use and product preservation, ultimately improving customer satisfaction.

Environmental Impact and Recyclability

Fitment pouches often contain mixed materials and integrated plastic spouts, complicating recycling processes and increasing environmental impact due to lower recyclability rates. Spouted pouches, especially those made from mono-materials, offer improved recyclability and reduced ecological footprint by enabling easier material separation and processing. Choosing spouted pouches designed for recyclability supports sustainable packaging initiatives and helps minimize landfill waste.

Cost Comparison and Market Trends

Fitment pouches generally incur higher production costs due to complex manufacturing processes and customized dispensing features compared to spouted pouches, which benefit from simpler designs and mass production efficiencies. Market trends indicate a growing demand for fitment pouches in premium segments such as personal care and liquid food products, driven by enhanced convenience and user experience. Spouted pouches dominate high-volume markets like beverages and household chemicals, attributed to their cost-effectiveness and adaptability to automated filling systems.

Choosing the Right Pouch for Your Product

Choosing the right pouch for your product depends on its usage and convenience requirements. Fitment pouches offer resealable spouts ideal for liquids, allowing easy pouring and reducing spills, while spouted pouches provide flexible packaging with a built-in spout, perfect for on-the-go consumption or controlled dispensing. Your decision should consider product type, user experience, and packaging functionality to enhance customer satisfaction and preserve product integrity.

Fitment pouch vs spouted pouch Infographic

libmatt.com

libmatt.com