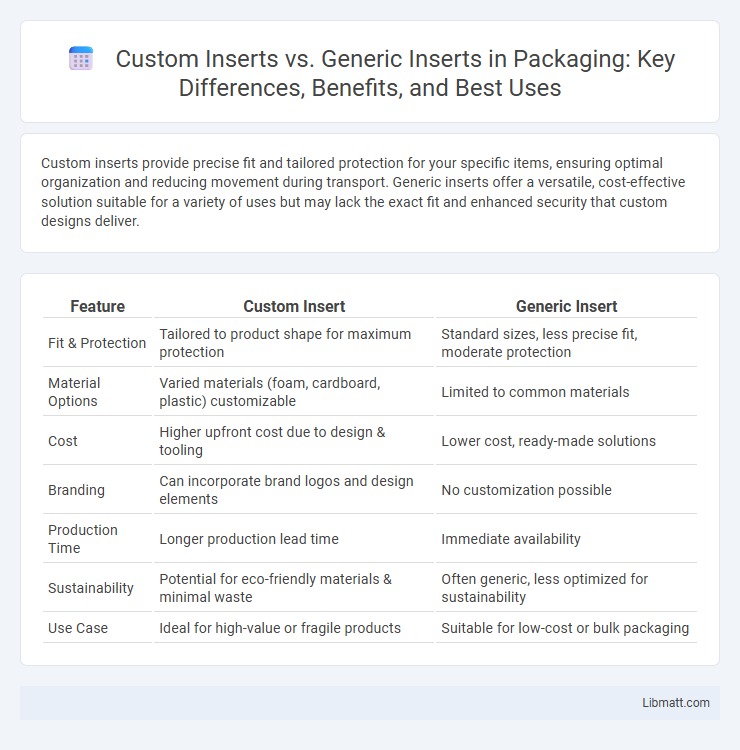

Custom inserts provide precise fit and tailored protection for your specific items, ensuring optimal organization and reducing movement during transport. Generic inserts offer a versatile, cost-effective solution suitable for a variety of uses but may lack the exact fit and enhanced security that custom designs deliver.

Table of Comparison

| Feature | Custom Insert | Generic Insert |

|---|---|---|

| Fit & Protection | Tailored to product shape for maximum protection | Standard sizes, less precise fit, moderate protection |

| Material Options | Varied materials (foam, cardboard, plastic) customizable | Limited to common materials |

| Cost | Higher upfront cost due to design & tooling | Lower cost, ready-made solutions |

| Branding | Can incorporate brand logos and design elements | No customization possible |

| Production Time | Longer production lead time | Immediate availability |

| Sustainability | Potential for eco-friendly materials & minimal waste | Often generic, less optimized for sustainability |

| Use Case | Ideal for high-value or fragile products | Suitable for low-cost or bulk packaging |

Introduction to Custom and Generic Inserts

Custom inserts are specifically designed to fit unique product dimensions and branding requirements, offering enhanced protection and presentation for specialized items. Generic inserts are mass-produced and versatile, suitable for a wide range of products but lacking tailored fit and bespoke aesthetics. Choosing between custom and generic inserts impacts packaging efficiency, cost, and user experience.

Key Differences Between Custom and Generic Inserts

Custom inserts are specifically designed for unique device shapes or requirements, providing precise fit and enhanced protection, while generic inserts offer standard dimensions suitable for a variety of applications but may lack tailored support. The material composition and cushioning technology in custom inserts are often engineered to match specific durability and comfort needs, unlike generic versions which prioritize broad compatibility. Choosing the right insert impacts the longevity and safety of your equipment, making custom inserts ideal for specialized use cases and generic inserts suitable for general purposes.

Benefits of Using Custom Inserts

Custom inserts provide tailored protection for your products by precisely fitting their shape and size, reducing movement and damage during transit. Your packaging gains a professional look that enhances brand perception and customer experience, ensuring your items arrive in pristine condition. Using custom inserts also optimizes space within packaging, potentially lowering shipping costs by minimizing wasted volume.

Advantages of Generic Inserts

Generic inserts offer broad compatibility across multiple firearm models, reducing the need for multiple custom parts and lowering overall costs for manufacturers and users. Their standardized design simplifies maintenance and replacement processes, ensuring easier availability and faster turnaround times. Generic inserts enhance versatility, making them ideal for users who own various firearms or seek cost-effective upgrade options.

Cost Comparison: Custom vs Generic Inserts

Custom inserts typically involve higher initial costs due to tailored design, specialized materials, and manufacturing processes, making them a more significant upfront investment compared to generic inserts. Generic inserts benefit from mass production efficiencies, resulting in lower per-unit costs but may lack the precise fit and durability that custom options provide. Your decision should weigh the long-term value of custom inserts' improved protection and functionality against the budget-friendly appeal of generic alternatives.

Applications Suited for Custom Inserts

Custom inserts provide tailored solutions for specialized applications requiring precise fit, enhanced protection, or unique organization, such as high-end electronics, medical instruments, and luxury packaging. These inserts improve product presentation and reduce shipping damage by conforming exactly to item dimensions and materials. Industries demanding high customization and superior impact resistance benefit significantly from custom inserts compared to generic options.

Ideal Scenarios for Generic Inserts

Generic inserts excel in scenarios requiring flexibility and cost-efficiency, such as large-scale inventory management and standard product packaging. They are optimal when your project demands a one-size-fits-all solution that simplifies production and reduces lead times. Utilizing generic inserts streamlines assembly processes and supports diverse item compatibility without sacrificing basic protection.

Factors to Consider When Choosing Inserts

Choosing between custom inserts and generic inserts depends on factors like product protection, production volume, and budget constraints. Custom inserts offer tailored fit and enhanced protection, ideal for high-value or delicate items, while generic inserts provide cost-effective, versatile solutions for larger quantities. Evaluating your product's fragility, packaging requirements, and overall cost-efficiency ensures the best insert choice for your needs.

Industry Case Studies: Custom vs Generic Inserts

Industry case studies reveal that custom inserts significantly enhance tool life and machining precision compared to generic inserts, particularly in aerospace and automotive manufacturing. Custom inserts are tailored to specific materials and cutting conditions, resulting in improved surface finish and reduced cycle times. Data from these studies indicate a 20-30% increase in productivity and cost savings when using custom inserts over generic alternatives.

Conclusion: Which Insert is Right for You?

Choosing between a custom insert and a generic insert depends on your specific needs for fit, protection, and organization. Custom inserts are precisely tailored to your items, offering superior protection and a sleek appearance, while generic inserts provide versatility and cost-effectiveness for varied uses. Your decision should balance the importance of personalized fit and durability against budget and flexibility requirements.

Custom insert vs generic insert Infographic

libmatt.com

libmatt.com