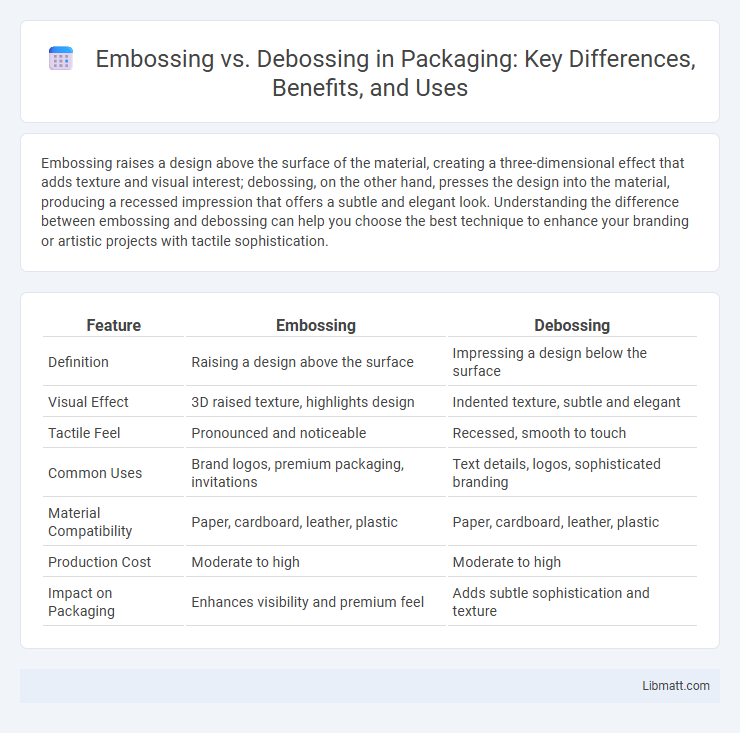

Embossing raises a design above the surface of the material, creating a three-dimensional effect that adds texture and visual interest; debossing, on the other hand, presses the design into the material, producing a recessed impression that offers a subtle and elegant look. Understanding the difference between embossing and debossing can help you choose the best technique to enhance your branding or artistic projects with tactile sophistication.

Table of Comparison

| Feature | Embossing | Debossing |

|---|---|---|

| Definition | Raising a design above the surface | Impressing a design below the surface |

| Visual Effect | 3D raised texture, highlights design | Indented texture, subtle and elegant |

| Tactile Feel | Pronounced and noticeable | Recessed, smooth to touch |

| Common Uses | Brand logos, premium packaging, invitations | Text details, logos, sophisticated branding |

| Material Compatibility | Paper, cardboard, leather, plastic | Paper, cardboard, leather, plastic |

| Production Cost | Moderate to high | Moderate to high |

| Impact on Packaging | Enhances visibility and premium feel | Adds subtle sophistication and texture |

Understanding Embossing and Debossing

Embossing raises your design above the surface of the material, creating a three-dimensional effect that adds texture and visual interest. Debossing, on the other hand, presses the design into the material, resulting in an indented impression that offers a more subtle, refined look. Understanding these techniques enables you to choose the best method to enhance your branding or product presentation.

Key Differences Between Embossing and Debossing

Embossing creates a raised impression on paper or materials, adding texture and visual depth, while debossing produces an indented or recessed design, pressing the image inward. Both techniques enhance branding and design but differ in visual impact and tactile experience, with embossing offering a more pronounced, standout effect, and debossing providing subtle elegance. Understanding these key differences helps you choose the right finishing method to elevate your printed materials effectively.

The Embossing Process Explained

Embossing is a printing technique that creates a raised, three-dimensional design on paper or other materials by pressing a die into the surface from underneath. This process involves using a matched pair of metal dies--one male (raised) and one female (recessed)--to shape the material and produce a tactile effect without ink or foil. Embossing enhances visual appeal and texture, commonly applied in business cards, packaging, and stationery for a luxurious finish.

How Debossing Works

Debossing presses an image or design into the paper surface, creating a recessed effect by pushing the material downward using a metal die. This process involves applying pressure from both sides of the paper or cardstock, often with heat, to permanently imprint the design. The depth and clarity of the debossed image depend on the type of paper and the pressure applied during the embossing process.

Design Considerations for Embossing and Debossing

Design considerations for embossing and debossing involve selecting suitable materials like thick cardstock or leather that can hold the raised or recessed impressions without tearing. Your artwork should feature clear, simple lines and avoid fine details, as these may not transfer well during the embossing or debossing process. Proper alignment and pressure settings are crucial to achieve consistent depth and sharpness in the final design.

Common Applications of Embossing

Embossing is commonly used in luxury packaging, business cards, and book covers to create a raised, tactile effect that enhances brand perception and visual appeal. This technique is ideal for highlighting logos, text, or patterns, providing a sophisticated and professional finish that grabs the attention of your audience. You can also find embossing in stationery, invitations, and product labels where a textured look adds an element of elegance and distinction.

Popular Uses of Debossing

Debossing is popularly used in luxury packaging, business cards, and book covers to create a sophisticated and tactile impression that enhances brand identity. It is favored in stationery and leather goods for adding subtle depth without compromising the surface texture. The technique is also common in invitations and corporate materials where understated elegance is desired.

Pros and Cons of Embossing vs Debossing

Embossing creates a raised impression on paper or other materials, enhancing tactile appeal and visual impact, but it may increase production costs and is less effective on textured surfaces. Debossing, which presses the design into the material, offers a subtle and elegant look while being more versatile with different substrates, though it can be less noticeable without additional finishing like foil or ink. Your choice depends on the desired aesthetic, budget, and material compatibility for optimal branding results.

Choosing the Right Technique for Your Project

Embossing raises a design above the paper surface to create a textured, three-dimensional effect, ideal for adding elegance to invitations and packaging. Debossing presses the design into the material, producing a recessed impression that offers a subtle, sophisticated look perfect for logos and business cards. Selecting the right technique depends on the desired visual impact, material type, and project goals, ensuring the finish enhances brand identity and tactile appeal.

Final Thoughts on Embossing and Debossing

Embossing raises your design above the surface, creating a tactile, visually striking effect, while debossing presses the design into the material for a subtle, elegant impression. Both techniques enhance branding and packaging by adding texture and depth, making your product stand out in a crowded market. Choosing between embossing and debossing depends on the desired aesthetic impact and the specific message you want your design to convey.

Embossing vs debossing Infographic

libmatt.com

libmatt.com