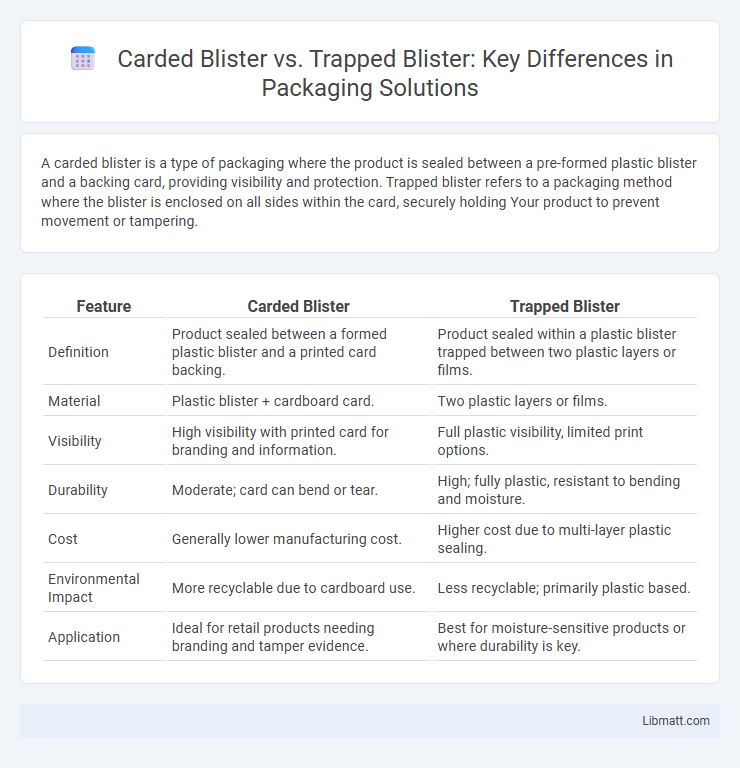

A carded blister is a type of packaging where the product is sealed between a pre-formed plastic blister and a backing card, providing visibility and protection. Trapped blister refers to a packaging method where the blister is enclosed on all sides within the card, securely holding Your product to prevent movement or tampering.

Table of Comparison

| Feature | Carded Blister | Trapped Blister |

|---|---|---|

| Definition | Product sealed between a formed plastic blister and a printed card backing. | Product sealed within a plastic blister trapped between two plastic layers or films. |

| Material | Plastic blister + cardboard card. | Two plastic layers or films. |

| Visibility | High visibility with printed card for branding and information. | Full plastic visibility, limited print options. |

| Durability | Moderate; card can bend or tear. | High; fully plastic, resistant to bending and moisture. |

| Cost | Generally lower manufacturing cost. | Higher cost due to multi-layer plastic sealing. |

| Environmental Impact | More recyclable due to cardboard use. | Less recyclable; primarily plastic based. |

| Application | Ideal for retail products needing branding and tamper evidence. | Best for moisture-sensitive products or where durability is key. |

Introduction to Blister Packaging

Carded blister packaging consists of pre-formed plastic cavities sealed onto a printed card backing, offering product visibility and protection ideal for retail display. Trapped blister packaging involves sealing a product between two layers of plastic or plastic and foil, ensuring enhanced tamper resistance and product security. Both packaging types optimize product presentation and preservation, catering to different market and handling requirements.

What is a Carded Blister?

A carded blister is a type of packaging that combines a pre-formed plastic blister with a backing card, typically made of cardboard or paperboard, securely holding the product in place. This packaging method enhances product visibility and provides ample space for branding, product information, and barcodes on the card backing. Carded blisters are commonly used for small consumer goods like electronics, toys, and hardware to offer tamper resistance and ease of display.

What is a Trapped Blister?

A trapped blister forms when fluid accumulates beneath the skin due to friction or pressure, causing a raised, fluid-filled cavity without skin breakage. Unlike carded blisters, which often result from burns or chemical exposure with a different layering of skin damage, trapped blisters are primarily caused by mechanical forces such as repetitive rubbing. Proper care involves protecting the blister to prevent rupture and infection while allowing natural healing of the underlying tissue.

Key Differences Between Carded and Trapped Blisters

Carded blisters feature a plastic bubble sealed onto a cardboard backing, allowing product visibility while providing a sturdy, flat surface for branding and information. Trapped blisters encase the product between two clear plastic layers sealed around the edges, offering better protection and tamper resistance but limited printing space. The key difference lies in the packaging structure, with carded blisters emphasizing presentation and trapped blisters prioritizing security and product protection.

Material Comparison: Carded vs Trapped Blister Packs

Carded blister packs use a pre-formed plastic cavity sealed to a backing card, offering rigidity and ease of display, while trapped blister packs sandwich the product between two plastic layers, providing enhanced protection against moisture and tampering. The materials in carded blisters often include PET or PVC plastic paired with a cardboard backing, which balances cost and presentation quality. Your choice depends on the need for visibility, durability, and environmental considerations, as trapped blisters typically offer superior barrier properties but may require higher material costs.

Product Protection and Security

Carded blister packaging offers enhanced product protection by securely sealing items between a pre-formed plastic cavity and a cardboard backing, preventing tampering and environmental damage. Trapped blister packaging encases the product between two plastic layers, providing a robust barrier against contamination but less tamper-evidence compared to carded blisters. Both types ensure product security, with carded blisters excelling in visual tamper indication and trapped blisters offering strong physical protection.

Packaging Design and Branding Opportunities

Carded blister packaging offers a larger surface area for vibrant graphics, detailed product information, and brand messaging, enhancing shelf appeal and consumer engagement. Trapped blister packaging provides a sleek, minimalistic look with sealed edges that protect the product while allowing clear visibility, ideal for premium branding. Your choice impacts brand perception and marketing effectiveness by balancing visual communication with product protection.

Environmental Impact and Sustainability

Carded blisters typically involve more plastic and cardboard layers, increasing material consumption and environmental footprint compared to trapped blisters, which use fewer materials and often incorporate recyclable components. Trapped blisters reduce waste generation by minimizing packaging volume, enhancing sustainability through improved recyclability and lower resource use. Your choice of blister packaging influences packaging waste reduction and supports eco-friendly supply chain practices.

Cost Efficiency and Production Considerations

Carded blisters typically incur higher material costs due to the additional cardboard backing but allow for easier product presentation and branding, enhancing consumer appeal. Trapped blisters reduce packaging expenses by eliminating the need for card stock, which can lower production time and waste, making them ideal for high-volume, cost-sensitive products. Production efficiency with trapped blisters is improved through streamlined machinery setup and faster sealing processes, whereas carded blisters may require more precise alignment and additional handling steps.

Choosing the Right Blister Packaging for Your Product

Choosing the right blister packaging for your product depends on factors like product protection, visibility, and durability. Carded blisters offer easy customization, excellent branding opportunities, and secure sealing ideal for retail displays, while trapped blisters provide enhanced product security by enclosing items between two plastic layers, preventing tampering. Assess your product's fragility and retail environment to determine whether carded or trapped blister packaging best meets your packaging needs and customer expectations.

Carded blister vs trapped blister Infographic

libmatt.com

libmatt.com