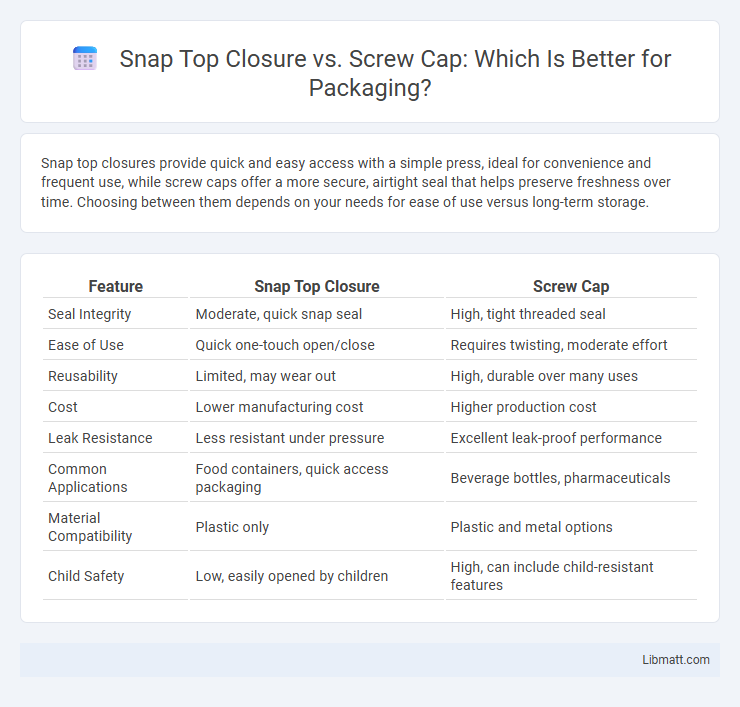

Snap top closures provide quick and easy access with a simple press, ideal for convenience and frequent use, while screw caps offer a more secure, airtight seal that helps preserve freshness over time. Choosing between them depends on your needs for ease of use versus long-term storage.

Table of Comparison

| Feature | Snap Top Closure | Screw Cap |

|---|---|---|

| Seal Integrity | Moderate, quick snap seal | High, tight threaded seal |

| Ease of Use | Quick one-touch open/close | Requires twisting, moderate effort |

| Reusability | Limited, may wear out | High, durable over many uses |

| Cost | Lower manufacturing cost | Higher production cost |

| Leak Resistance | Less resistant under pressure | Excellent leak-proof performance |

| Common Applications | Food containers, quick access packaging | Beverage bottles, pharmaceuticals |

| Material Compatibility | Plastic only | Plastic and metal options |

| Child Safety | Low, easily opened by children | High, can include child-resistant features |

Introduction to Snap Top Closures and Screw Caps

Snap top closures offer a convenient, quick-seal solution commonly used for food and beverage containers, providing easy access with a simple press or snap mechanism. Screw caps, featuring threaded designs, ensure airtight sealing and reusability, ideal for products requiring secure packaging and preservation. Your choice between snap top closures and screw caps depends on the need for convenience, resealability, and product protection.

Key Differences Between Snap Top and Screw Cap Designs

Snap top closures provide quick and easy access with a simple push-to-open mechanism, ideal for convenience and frequent use, while screw caps ensure a secure, airtight seal, enhancing product freshness and leak prevention. Snap tops are typically favored in packaging for products requiring immediate access without twisting, whereas screw caps offer superior durability in shipping and storage. Your choice between these closures should consider the balance between ease of use and the necessity for airtight protection.

Material Compatibility: Snap Tops vs Screw Caps

Snap top closures excel in quick access and convenience but may have limited material compatibility, often preferred for lightweight plastics like polyethylene or polypropylene. Screw caps provide superior sealing with versatile compatibility across diverse materials including glass and various plastics, ensuring chemical resistance and durability. Your choice depends on the container's contents and required seal integrity for optimal performance.

Ease of Use and Consumer Convenience

Snap top closures provide quick and effortless access by allowing you to open and close containers with a simple press, ideal for frequent use and on-the-go convenience. Screw caps offer a secure seal but require twisting, which may be less convenient for one-handed operation or repeated access. Both closure types enhance consumer convenience, with snap tops excelling in ease of use and screw caps providing reliable resealing.

Seal Security and Leak Protection Comparison

Snap top closures provide quick and convenient sealing but often lack the robust seal security required for high-impact or pressure-sensitive contents, making them more prone to leakage under stress or temperature changes. Screw caps create a tighter, more consistent seal through threading, significantly enhancing leak protection and reducing the risk of contamination or spillage, which is essential for pharmaceutical, food, and chemical packaging. In applications demanding reliable long-term seal integrity, screw caps outperform snap tops by maintaining pressure resistance and minimizing failure rates during transport and storage.

Applications in Food, Beverage, and Cosmetic Packaging

Snap top closures provide quick and easy access, making them ideal for single-use food packaging, such as yogurt cups and snack containers, where convenience is key. Screw caps offer superior airtight sealing widely used in beverage bottles and cosmetic jars to preserve freshness and prevent leakage. In cosmetic packaging, screw caps are favored for products like creams and lotions due to their reliable resealing properties and tamper evidence.

Environmental Impact: Recyclability and Sustainability

Snap top closures often use less material and can be made from recyclable plastics, contributing to reduced environmental impact by facilitating easier separation during recycling. Screw caps, especially those made from aluminum or plastic, are highly recyclable but sometimes detach from the bottle, complicating the recycling process. Choosing closures designed for material compatibility and recyclability enhances sustainability in packaging by promoting efficient resource use and waste reduction.

Cost Efficiency and Manufacturing Considerations

Snap top closures offer cost efficiency through lower material costs and faster assembly, making them ideal for high-volume production runs. Screw caps provide superior sealing but often require more complex manufacturing processes and higher tooling expenses. Your choice depends on balancing upfront production costs with long-term performance needs.

Branding and Customization Options

Snap top closures offer versatile branding opportunities with customizable colors, embossed logos, and unique shapes that enhance product differentiation on shelves. Screw caps provide a broad range of customization through printed labels, tamper-evident features, and die-cut designs, ensuring strong brand visibility and consumer trust. Both closure types cater to distinct packaging aesthetics and brand identity strategies, making them essential choices in product presentation.

Choosing the Right Closure: Factors to Consider

Choosing the right closure involves evaluating factors such as ease of use, seal integrity, and product compatibility. Snap top closures offer quick access and convenience, ideal for products requiring frequent opening, while screw caps provide a tighter seal suitable for liquids needing long-term preservation. Understanding your product's storage conditions and usage patterns helps determine whether a snap top or screw cap best maintains quality and user experience.

Snap top closure vs screw cap Infographic

libmatt.com

libmatt.com