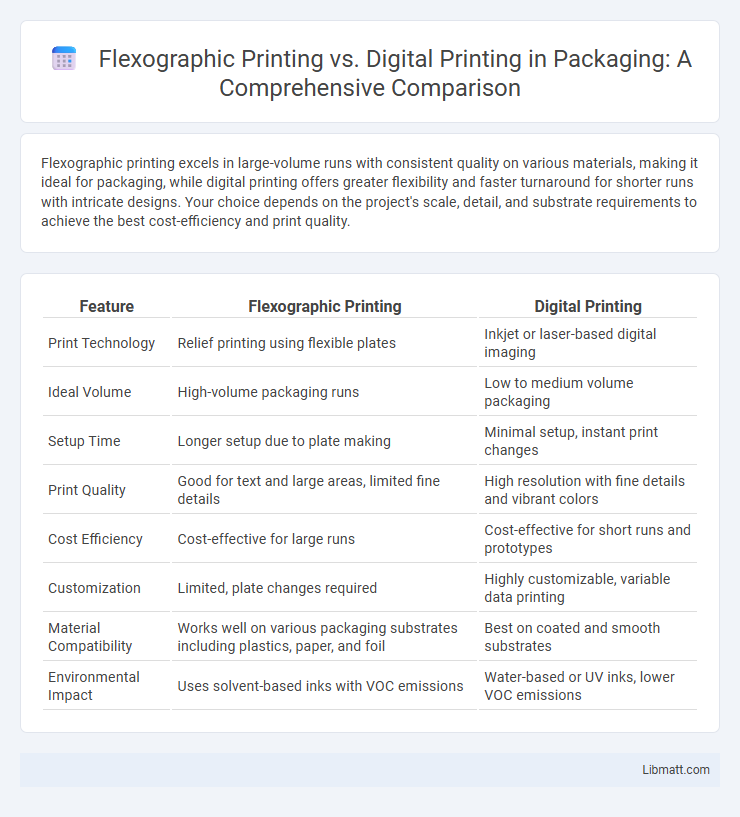

Flexographic printing excels in large-volume runs with consistent quality on various materials, making it ideal for packaging, while digital printing offers greater flexibility and faster turnaround for shorter runs with intricate designs. Your choice depends on the project's scale, detail, and substrate requirements to achieve the best cost-efficiency and print quality.

Table of Comparison

| Feature | Flexographic Printing | Digital Printing |

|---|---|---|

| Print Technology | Relief printing using flexible plates | Inkjet or laser-based digital imaging |

| Ideal Volume | High-volume packaging runs | Low to medium volume packaging |

| Setup Time | Longer setup due to plate making | Minimal setup, instant print changes |

| Print Quality | Good for text and large areas, limited fine details | High resolution with fine details and vibrant colors |

| Cost Efficiency | Cost-effective for large runs | Cost-effective for short runs and prototypes |

| Customization | Limited, plate changes required | Highly customizable, variable data printing |

| Material Compatibility | Works well on various packaging substrates including plastics, paper, and foil | Best on coated and smooth substrates |

| Environmental Impact | Uses solvent-based inks with VOC emissions | Water-based or UV inks, lower VOC emissions |

Introduction to Flexographic and Digital Printing

Flexographic printing utilizes flexible relief plates and fast-drying inks, making it ideal for high-volume packaging and label production with consistent quality. Digital printing employs inkjet or laser technology, offering quick turnaround times and customization without the need for printing plates. Both methods serve distinct industrial needs, with flexography excelling in large runs and digital printing suited for short runs and variable data printing.

Key Differences Between Flexographic and Digital Printing

Flexographic printing utilizes flexible relief plates and fast-drying inks, making it ideal for high-volume runs with consistent image quality and vibrant colors on various substrates like plastic, foil, and paper. Digital printing offers superior customization and quicker turnaround by directly transferring digital images onto materials, best suited for low to medium print volumes and detailed, variable data printing. The main differences lie in setup costs, print speed, versatility, and the ability to handle complex color gradients, with flexo excelling in bulk jobs and digital excelling in agility and personalization.

Printing Process Overview: Flexography vs Digital

Flexographic printing uses flexible relief plates to transfer ink onto a variety of substrates through a rotary press, ideal for high-volume runs with consistent image quality. Digital printing employs inkjet or laser technology to directly apply ink onto media, allowing for rapid setup and customization with minimal waste. Understanding these distinct printing processes helps you select the best method for your project based on volume, detail, and turnaround time.

Material Compatibility and Substrate Options

Flexographic printing offers broad material compatibility, excelling with flexible substrates such as plastic, metallic films, and paper, making it ideal for packaging applications. Digital printing supports a variety of substrates, including coated and uncoated papers, cardstock, and some plastics, but may face limitations with highly absorbent or textured materials. Your choice between flexographic and digital printing should consider the specific substrate properties to ensure optimal print quality and durability.

Print Quality and Resolution Comparison

Flexographic printing excels in high-speed production with consistent color density but generally offers lower resolution, typically around 300-600 dpi, making it ideal for large runs and packaging labels. Digital printing provides superior print quality with resolutions up to 1200 dpi or higher, delivering sharper images and finer details suitable for intricate graphics and short runs. While flexography favors durability and efficiency on various substrates, digital printing shines in customization and rapid turnaround without the need for plates.

Speed and Efficiency in Production

Flexographic printing excels in high-speed production runs, capable of printing thousands of units per hour with consistent quality, making it ideal for large-scale packaging and label printing. Digital printing offers superior efficiency for short runs and rapid turnaround times, eliminating the need for plate setup and allowing immediate output adjustments. While flexography is cost-effective for bulk production, digital printing provides flexibility and speed for customized or on-demand jobs, optimizing workflow based on order volume.

Cost Analysis: Flexographic vs Digital Printing

Flexographic printing offers lower unit costs for large-volume runs due to its ability to produce consistent high-speed outputs, making it cost-effective for bulk packaging and labels. Digital printing incurs higher costs per unit but eliminates setup expenses, ideal for short runs and customized prints with quick turnaround times. Your choice depends on balancing initial setup costs and print volume to optimize overall production expenses.

Flexibility and Customization Capabilities

Flexographic printing excels in high-volume runs with consistent quality, offering flexibility in substrate choices such as plastics, paper, and metallic films, making it suitable for large-scale packaging. Digital printing provides superior customization capabilities with easy adjustments for variable data and short runs, enabling you to create personalized designs without additional setup costs. While flexography is cost-effective for bulk production, digital printing offers unmatched adaptability for diverse and intricate print jobs.

Environmental Impact and Sustainability

Flexographic printing often uses solvent-based inks and produces higher waste due to plate and setup processes, leading to increased environmental impact compared to digital printing. Digital printing employs water-based or UV-curable inks, minimizing chemical emissions and reducing materials waste through on-demand production. The sustainability advantage of digital printing lies in its energy efficiency, reduced water usage, and lower carbon footprint, making it a more eco-friendly choice for short to medium print runs.

Choosing the Right Printing Method for Your Needs

Flexographic printing excels in high-volume runs with consistent quality and cost-efficiency, making it ideal for packaging, labels, and flexible materials. Digital printing offers superior customization, faster turnaround, and variable data capabilities, suitable for short runs, prototype designs, and personalized marketing materials. Assessing factors like print volume, material type, budget, and design complexity helps determine whether flexographic or digital printing best aligns with your project requirements.

Flexographic printing vs digital printing Infographic

libmatt.com

libmatt.com