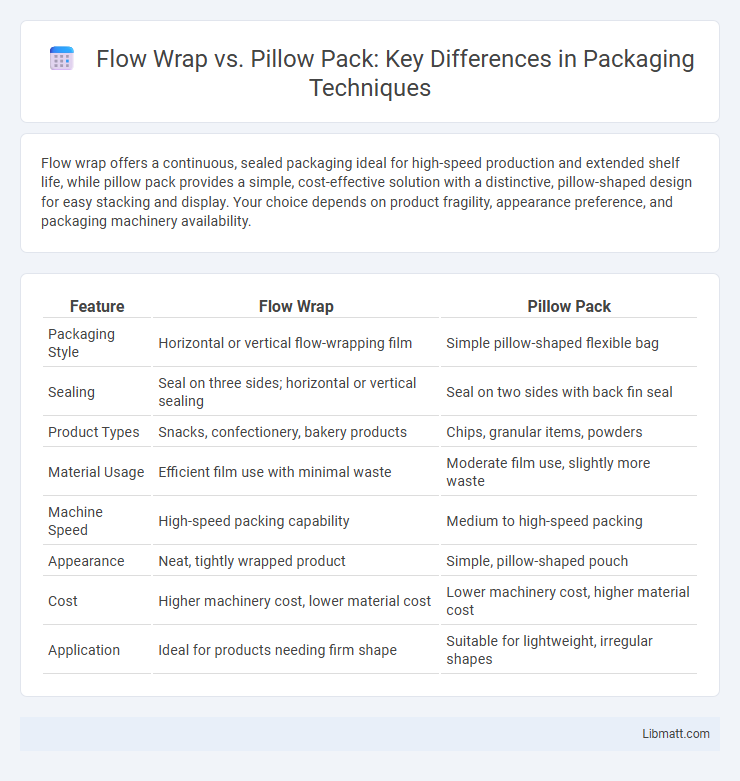

Flow wrap offers a continuous, sealed packaging ideal for high-speed production and extended shelf life, while pillow pack provides a simple, cost-effective solution with a distinctive, pillow-shaped design for easy stacking and display. Your choice depends on product fragility, appearance preference, and packaging machinery availability.

Table of Comparison

| Feature | Flow Wrap | Pillow Pack |

|---|---|---|

| Packaging Style | Horizontal or vertical flow-wrapping film | Simple pillow-shaped flexible bag |

| Sealing | Seal on three sides; horizontal or vertical sealing | Seal on two sides with back fin seal |

| Product Types | Snacks, confectionery, bakery products | Chips, granular items, powders |

| Material Usage | Efficient film use with minimal waste | Moderate film use, slightly more waste |

| Machine Speed | High-speed packing capability | Medium to high-speed packing |

| Appearance | Neat, tightly wrapped product | Simple, pillow-shaped pouch |

| Cost | Higher machinery cost, lower material cost | Lower machinery cost, higher material cost |

| Application | Ideal for products needing firm shape | Suitable for lightweight, irregular shapes |

Introduction to Flow Wrap and Pillow Pack Packaging

Flow wrap packaging offers a continuous film that tightly seals products, providing excellent protection and visibility, ideal for items such as snacks and confectionery. Pillow pack packaging features a flexible pouch sealed at both ends, creating a distinctive pillow shape commonly used for small, lightweight goods like chips and cookies. Your choice between flow wrap and pillow pack depends on product type, shelf appeal, and packaging efficiency.

How Flow Wrap Packaging Works

Flow wrap packaging operates by continuously feeding a product onto a moving plastic film, which then wraps tightly around it as heat-sealing jaws create airtight seals along the length of the package. The film is shaped around the product through folding mechanisms and sealed both longitudinally and transversely, resulting in a secure, tamper-evident package ideal for irregularly shaped items. This method ensures product freshness and protection by minimizing air exposure and providing a durable, transparent wrapper for easy consumer visibility.

How Pillow Pack Packaging Works

Pillow pack packaging works by folding flexible film around the product, sealing the edges on the back to create a pillow-shaped package that securely protects contents from contamination and damage. This method uses horizontal or vertical form-fill-seal machines to efficiently wrap items like snacks, baked goods, and small hardware components. Your product benefits from airtight sealing and cost-effective packaging, preserving freshness while offering excellent print surface for branding.

Key Differences Between Flow Wrap and Pillow Pack

Flow wrap packaging uses a continuous roll of film to enclose products in a tight, sealed wrap ideal for irregular shapes, providing high-speed production line compatibility. Pillow pack features a flat, pillow-shaped pouch formed by sealed edges on three sides, offering efficient storage and a neat presentation for flat or flexible items. Flow wrap excels in protection and visibility for complex items, while pillow packs prioritize packing simplicity and shelf-edge appeal.

Advantages of Flow Wrap Packaging

Flow wrap packaging offers superior product protection through a continuous film seal that reduces contamination and extends shelf life. Its flexible design allows for efficient automated wrapping of various shapes and sizes, enhancing production speed and reducing labor costs. You benefit from improved product visibility and tamper evidence, making flow wrap ideal for ensuring both safety and consumer appeal.

Advantages of Pillow Pack Packaging

Pillow pack packaging offers advantages such as efficient space utilization due to its compact and flexible shape, enabling better shelf display and easier handling. It provides excellent barrier properties that protect products from moisture, oxygen, and contaminants, enhancing shelf life and product freshness. The pillow pack's cost-effective production process and versatility in packaging various product types make it a preferred choice for many manufacturers.

Applications of Flow Wrap in Various Industries

Flow wrap packaging excels in industries such as food, pharmaceuticals, and consumer goods due to its ability to create airtight seals that extend product freshness and shelf life. Its versatility accommodates irregularly shaped items, making it ideal for packaging bakery products, confectionery, medical supplies, and personal care items. You benefit from the enhanced protection and attractive presentation that flow wrap delivers, boosting product appeal across diverse market sectors.

Applications of Pillow Pack in Various Industries

Pillow pack is extensively used in the food industry for packaging snacks, confectionery, and bakery products due to its efficient sealing and airtight properties that enhance product freshness. In the pharmaceutical sector, pillow packs provide secure packaging for medical supplies and over-the-counter medications, ensuring contamination prevention and dose accuracy. Personal care and household product manufacturers also prefer pillow pack for sachets and single-use items, benefiting from its cost-effectiveness and versatility in packaging diverse small-volume products.

Factors to Consider When Choosing Between Flow Wrap and Pillow Pack

When choosing between Flow Wrap and Pillow Pack, consider factors such as product shape, packaging speed, and sealing requirements. Flow Wrap offers continuous, high-speed packaging ideal for irregular or elongated items, while Pillow Pack suits more uniform shapes and provides a simple, cost-effective seal. Your decision should prioritize product protection, visual appeal, and the packaging machine compatibility to ensure efficiency and quality.

Future Trends in Flexible Packaging Technologies

Flow wrap and pillow pack technologies are evolving with advancements in biodegradable films, smart packaging, and improved sealing techniques that enhance shelf life and product protection. Integration of IoT sensors and eco-friendly materials is driving sustainable packaging solutions to meet consumer demand and regulatory requirements. Future trends emphasize lightweight, recyclable, and multi-layer barrier films that support automation and reduce environmental impact in flexible packaging industries.

Flow wrap vs pillow pack Infographic

libmatt.com

libmatt.com