Stretch hoods provide flexible, elastic coverage by stretching over pallet loads to secure and protect goods, offering superior tension and quick application. Shrink hoods rely on heat to contract tightly around the load, ensuring a snug fit that safeguards against moisture and contamination during transport.

Table of Comparison

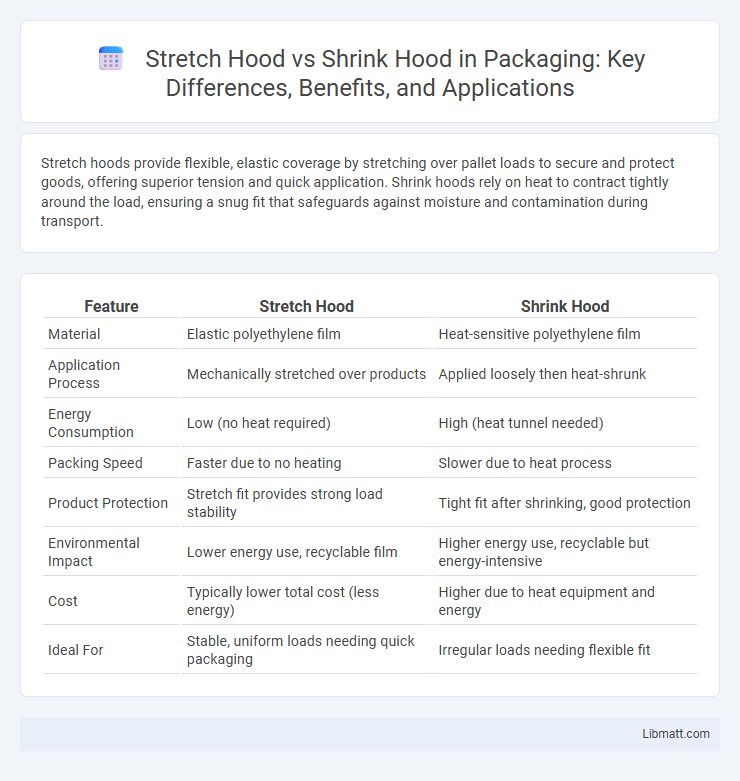

| Feature | Stretch Hood | Shrink Hood |

|---|---|---|

| Material | Elastic polyethylene film | Heat-sensitive polyethylene film |

| Application Process | Mechanically stretched over products | Applied loosely then heat-shrunk |

| Energy Consumption | Low (no heat required) | High (heat tunnel needed) |

| Packing Speed | Faster due to no heating | Slower due to heat process |

| Product Protection | Stretch fit provides strong load stability | Tight fit after shrinking, good protection |

| Environmental Impact | Lower energy use, recyclable film | Higher energy use, recyclable but energy-intensive |

| Cost | Typically lower total cost (less energy) | Higher due to heat equipment and energy |

| Ideal For | Stable, uniform loads needing quick packaging | Irregular loads needing flexible fit |

Introduction to Stretch Hood and Shrink Hood Technologies

Stretch hood technology utilizes highly elastic polyethylene films that stretch over products, providing secure containment and protection during transportation and storage. Shrink hood employs heat application to shrink a plastic film tightly around the load, creating a snug fit that stabilizes and shields items. Your choice between stretch hood and shrink hood depends on product type, equipment compatibility, and environmental conditions, maximizing packaging efficiency and load stability.

Key Differences Between Stretch Hood and Shrink Hood

Stretch hood and shrink hood packaging both secure loads, but key differences lie in their material properties and application processes. Stretch hood uses elastic polyethylene film that stretches over the product, providing tension and stability without heat, while shrink hood requires heat application to conform tightly to the product through film contraction. Your choice depends on factors such as load type, equipment availability, and environmental conditions, impacting efficiency and protection.

Material Composition and Sustainability

Stretch hoods are typically made from polyethylene or polypropylene, providing elasticity that allows for a snug fit without the need for heat, which reduces energy consumption during application. Shrink hoods consist mainly of polyolefin films that require heat to conform tightly around products, resulting in higher energy usage but offering excellent puncture resistance. In terms of sustainability, stretch hoods generate less carbon footprint due to lower energy demand, while shrink hoods often use recyclable materials but may involve more complex recycling processes due to heat-induced alterations.

Application Methods and Equipment

Stretch hood packaging uses elasticized film that wraps tightly over products when stretched, requiring specialized stretch hood machines with film dispensers and tension control systems. Shrink hood involves applying a loose film around the pallet that shrinks upon heat exposure, using shrink tunnels or heat guns to conform the film to the load. Your choice depends on available equipment and desired packaging speed, as stretch hood machines typically enable faster, automated wrapping compared to the more manual or semi-automated shrink hood application.

Packaging Performance and Protection

Stretch hood offers superior packaging performance with its elasticity, ensuring a tight fit that adapts to product dimensions, providing excellent protection against dust, moisture, and mechanical damage during transportation. Shrink hood relies on heat to conform tightly around products, delivering strong barrier properties but potentially risking stress on fragile items due to heat application. Your choice between stretch hood and shrink hood should consider the level of protection required and the nature of your products to optimize packaging efficiency and safeguard goods.

Cost Comparison: Stretch Hood vs Shrink Hood

Stretch hoods typically offer lower overall costs due to reduced energy consumption and faster application times compared to shrink hoods, which require heat tunnels and higher energy usage. Shrink hoods involve increased operational expenses from specialized equipment and maintenance, leading to higher initial and ongoing costs. Your decision should consider these economic factors alongside packaging needs to optimize budget efficiency.

Energy Efficiency and Environmental Impact

Stretch hoods require significantly less energy compared to shrink hoods since they do not rely on heat tunnels, reducing overall power consumption during packaging. Shrink hoods consume high amounts of energy due to the heat needed to activate the film's shrinking properties, leading to increased carbon emissions and higher utility costs. Stretch hoods also minimize environmental impact by producing less plastic waste and enabling easier film recycling due to their simpler material composition and application process.

Suitability for Different Industries and Products

Stretch hood offers exceptional adaptability for industries handling irregularly shaped or bulky products, such as construction materials and palletized goods, ensuring secure containment with its elastic properties. Shrink hood is ideal for uniform, high-volume packaging in food, beverage, and pharmaceutical sectors, providing a tight, tamper-evident seal after heat application. Your choice between stretch hood and shrink hood should consider product shape, packaging speed, and industry-specific handling requirements to optimize protection and efficiency.

Market Trends and Innovations

Stretch hood packaging is gaining significant traction due to its superior elasticity, environmental benefits, and reduction in film usage compared to shrink hood systems, driving innovation in sustainable materials like bio-based polymers. Market trends indicate increasing adoption of automated stretch hood machinery, which enhances efficiency and reduces labor costs, while innovations in shrink hood technology focus on energy-efficient heat tunnels and improved film formulations for faster processing. Both packaging methods continue evolving with smart sensors and IoT integrations, enabling real-time monitoring and adaptive tension control to optimize load stability and reduce waste.

Choosing the Right Hooding Solution for Your Needs

Choosing between stretch hood and shrink hood solutions depends on your product's protection requirements and packaging line capabilities. Stretch hoods provide excellent load stability and extended protection with high elasticity materials, ideal for heavier or irregularly shaped products. Your decision should consider the cost-efficiency, environmental impact, and ease of application to ensure the hooding solution aligns with your operational goals and sustainability practices.

Stretch hood vs shrink hood Infographic

libmatt.com

libmatt.com