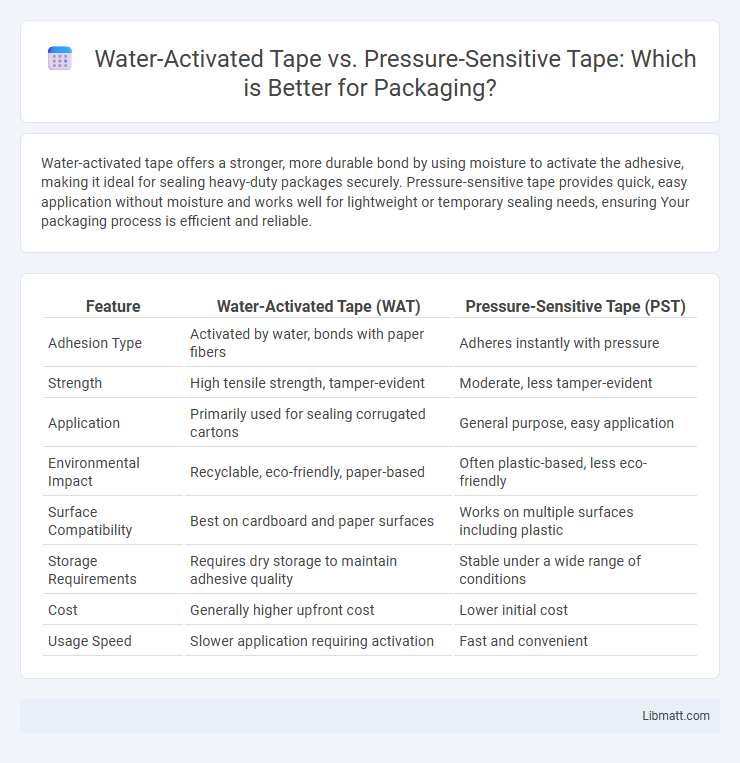

Water-activated tape offers a stronger, more durable bond by using moisture to activate the adhesive, making it ideal for sealing heavy-duty packages securely. Pressure-sensitive tape provides quick, easy application without moisture and works well for lightweight or temporary sealing needs, ensuring Your packaging process is efficient and reliable.

Table of Comparison

| Feature | Water-Activated Tape (WAT) | Pressure-Sensitive Tape (PST) |

|---|---|---|

| Adhesion Type | Activated by water, bonds with paper fibers | Adheres instantly with pressure |

| Strength | High tensile strength, tamper-evident | Moderate, less tamper-evident |

| Application | Primarily used for sealing corrugated cartons | General purpose, easy application |

| Environmental Impact | Recyclable, eco-friendly, paper-based | Often plastic-based, less eco-friendly |

| Surface Compatibility | Best on cardboard and paper surfaces | Works on multiple surfaces including plastic |

| Storage Requirements | Requires dry storage to maintain adhesive quality | Stable under a wide range of conditions |

| Cost | Generally higher upfront cost | Lower initial cost |

| Usage Speed | Slower application requiring activation | Fast and convenient |

Introduction to Water-Activated and Pressure-Sensitive Tapes

Water-activated tape, also known as gummed tape, features a cellulose backing coated with an adhesive that activates when moistened, creating a strong, tamper-evident seal ideal for packaging and shipping. Pressure-sensitive tape uses a solvent-based adhesive that sticks immediately upon application without moisture, making it suitable for quick sealing and general-purpose use. Your choice between these tapes depends on factors like bond strength, application speed, and package security requirements.

Composition and Material Differences

Water-activated tape, also known as gummed tape, is composed primarily of reinforced paper coated with a water-activated adhesive made from natural starch or synthetic polymers, ensuring a strong bond when moistened. In contrast, pressure-sensitive tape consists of a plastic film backing, such as polypropylene or PVC, coated with a sticky adhesive like rubber or acrylic that adheres instantly upon pressure without the need for water. Your choice between these tapes depends on the packaging requirements, as water-activated tape offers superior durability and tamper-evidence, while pressure-sensitive tape provides quick and convenient sealing.

How Water-Activated Tape Works

Water-activated tape, also known as gummed tape, features a starch-based adhesive that activates upon contact with moisture, creating a strong bond with the carton surface. Unlike pressure-sensitive tape, which relies on adhesive stickiness applied with pressure, water-activated tape fuses with the box fibers, enhancing security and tamper evidence. Your packaging process benefits from this adhesive technology by improving durability and ensuring sealed packages withstand transit conditions effectively.

How Pressure-Sensitive Tape Works

Pressure-sensitive tape adheres instantly when light pressure is applied, using a sticky adhesive that remains tacky without the need for water or heat activation. The adhesive's viscoelastic properties enable it to bond to surfaces by flowing into microscopic irregularities, creating a strong seal. Unlike water-activated tape, which requires moisture to activate the adhesive, pressure-sensitive tape offers quick and convenient application for various packaging and industrial uses.

Strength and Security Comparison

Water-activated tape offers superior strength and security due to its adhesive that bonds with the cardboard fibers, creating a tamper-evident seal ideal for heavy-duty packaging and shipping. Pressure-sensitive tape relies on a synthetic adhesive that adheres to the surface but can lose grip over time or under stress, making it less reliable for securing valuable or heavy parcels. The fiber-reinforced water-activated tape provides enhanced resistance to splitting and accidental openings compared to standard pressure-sensitive options.

Application Processes: Manual vs. Automated

Water-activated tape requires moistening before application, making it highly effective for secure seals but often necessitating wetter systems or manual wetting for activation. Pressure-sensitive tape adheres instantly with pressure, allowing easy manual application or use in high-speed automated taping machines. Choosing between these tapes depends on your packaging line's automation level and the desired sealing strength.

Environmental Sustainability and Recyclability

Water-activated tape, made from natural kraft paper and starch-based adhesives, offers superior environmental sustainability due to its biodegradable and compostable properties. Unlike pressure-sensitive tape, which often contains plastic backings and synthetic adhesives that complicate recycling processes, water-activated tape can be easily recycled with your cardboard packaging, minimizing landfill waste. Choosing water-activated tape supports eco-friendly packaging solutions by enhancing recyclability and reducing plastic pollution.

Cost Analysis: Upfront and Operational Expenses

Water-activated tape generally incurs higher upfront costs due to specialized dispensers but offers lower operational expenses with strong adhesive properties that reduce re-taping and damage. Pressure-sensitive tape has lower initial investment with no need for equipment but may lead to increased costs over time from diminished durability and frequent replacements. Your choice between the two tapes should balance initial budget constraints against long-term savings for packaging efficiency.

Industry Usage and Suitability

Water-activated tape is extensively used in industries requiring strong, tamper-evident seals such as packaging, shipping, and food processing due to its superior bonding with corrugated cardboard. Pressure-sensitive tape is ideal for quick application in light to medium-duty tasks across sectors like retail, office supplies, and household use, providing convenience without waiting for adhesive activation. Your choice depends on the need for moisture-resistant, secure sealing versus ease of use and speed in diverse industrial environments.

Choosing the Right Tape for Your Packaging Needs

Water-activated tape, made from natural fibers and adhesive activated by moisture, offers superior bonding strength and tamper-evident security for heavy-duty packaging. Pressure-sensitive tape, coated with a sticky adhesive on one side, provides convenience and quick application suitable for lightweight or temporary sealing. Selecting the right tape depends on the package weight, handling conditions, and required durability to ensure optimal protection and efficiency in shipping or storage.

Water-activated tape vs pressure-sensitive tape Infographic

libmatt.com

libmatt.com