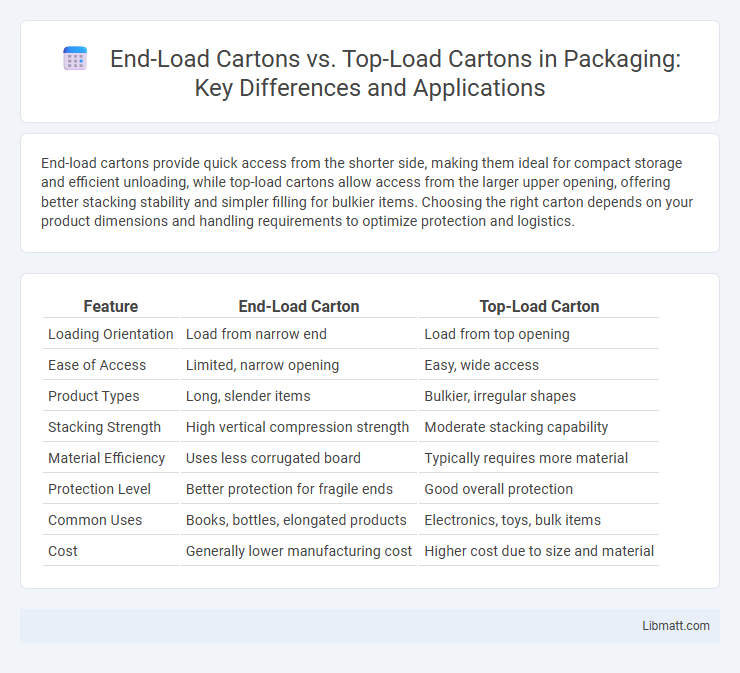

End-load cartons provide quick access from the shorter side, making them ideal for compact storage and efficient unloading, while top-load cartons allow access from the larger upper opening, offering better stacking stability and simpler filling for bulkier items. Choosing the right carton depends on your product dimensions and handling requirements to optimize protection and logistics.

Table of Comparison

| Feature | End-Load Carton | Top-Load Carton |

|---|---|---|

| Loading Orientation | Load from narrow end | Load from top opening |

| Ease of Access | Limited, narrow opening | Easy, wide access |

| Product Types | Long, slender items | Bulkier, irregular shapes |

| Stacking Strength | High vertical compression strength | Moderate stacking capability |

| Material Efficiency | Uses less corrugated board | Typically requires more material |

| Protection Level | Better protection for fragile ends | Good overall protection |

| Common Uses | Books, bottles, elongated products | Electronics, toys, bulk items |

| Cost | Generally lower manufacturing cost | Higher cost due to size and material |

Introduction to End-Load and Top-Load Cartons

End-load cartons feature a design where the product is accessed from the ends, making them ideal for elongated items like bottles or tubes, offering ease of loading and unloading in packaging lines. Top-load cartons open from the top, providing a more traditional configuration suitable for bulkier products and enabling efficient stacking and display on retail shelves. Choosing between end-load and top-load cartons depends on product dimensions, handling requirements, and retail display preferences to optimize protection and consumer accessibility.

Key Differences Between End-Load and Top-Load Cartons

End-load cartons open from one of the smaller ends, making them ideal for long, slender items, while top-load cartons open from the larger top side, offering easier access for bulkier products. You should consider end-load cartons for efficient stacking and space-saving during transportation, whereas top-load cartons provide convenience in loading and unloading heavier contents. The structural design and opening orientation significantly impact packaging efficiency and product protection, key differences that influence your choice based on the shape and handling requirements of your items.

Structural Design and Material Considerations

End-load cartons feature a structural design with flaps on the shorter ends, providing easier access and space for reinforced materials to enhance corner strength, while top-load cartons have flaps on the longer sides, offering superior stacking strength with added corrugated layers. Material considerations for end-load cartons often include heavier board grades to compensate for less surface area in the flap seals, whereas top-load cartons benefit from uniform wall thickness and are typically crafted from single-wall or double-wall corrugated fiberboard for durability. Choosing between these designs directly influences your packaging efficiency and product protection based on load distribution and material strength requirements.

Applications and Industry Usage

End-load cartons are widely used in industries requiring compact packaging and efficient stacking, such as pharmaceuticals and cosmetics, due to their easy access and secure closure. Top-load cartons dominate the food and beverage sector where product visibility and quick loading are essential, including frozen foods and beverages. Your choice between end-load and top-load cartons depends on specific packaging needs, including product type, handling, and display preferences.

Advantages of End-Load Cartons

End-load cartons offer superior stacking strength and protection, making them ideal for heavy or fragile items during shipping. Their easy access through the end flaps enhances packing efficiency and reduces labor costs in production lines. You benefit from improved durability and streamlined handling, ensuring products arrive intact and ready for display.

Advantages of Top-Load Cartons

Top-load cartons offer superior stacking strength and durability, making them ideal for heavy or fragile goods that require robust protection during shipping and storage. Their design allows easy access to contents from the top, facilitating efficient packing and unpacking in fast-paced warehouse environments. Enhanced product visibility and the ability to accommodate custom inserts contribute to better organization and presentation of merchandise.

Packaging Efficiency and Automation Compatibility

End-load cartons offer higher packaging efficiency for automated assembly lines due to their streamlined loading process, reducing cycle times and labor costs. Top-load cartons provide greater versatility for irregularly shaped products but often require slower manual or semi-automated packing methods. Automated systems typically favor end-load cartons for optimal throughput and minimal product handling errors.

Cost Factors and Economic Impact

End-load cartons typically offer lower material costs due to simpler construction and less complex machinery requirements, making them more economical for high-volume production. Top-load cartons, while potentially more expensive upfront because of intricate designs and additional sealing steps, can reduce product damage during transit, minimizing costly returns and losses. Your choice between end-load and top-load cartons should consider both initial packaging costs and the long-term economic impact related to product protection and handling efficiency.

Sustainability and Environmental Considerations

End-load cartons often use less material and generate less waste compared to top-load cartons, enhancing sustainability by reducing carbon emissions during production and transportation. Their design allows for easier stacking and more efficient palletizing, leading to improved space utilization and lower fuel consumption in distribution. In contrast, top-load cartons typically require more corrugated fiberboard and extra packaging for stability, increasing environmental impact and material waste.

Choosing the Right Carton for Your Product

Selecting the appropriate carton type hinges on your product's dimensions and handling requirements. End-load cartons provide easy access for longer items like posters or flat-pack furniture, enhancing loading efficiency, while top-load cartons are best suited for bulkier products needing vertical stacking and extra protection. Consider product fragility, weight distribution, and packaging line compatibility when deciding between end-load and top-load cartons to optimize both protection and logistics.

End-load carton vs top-load carton Infographic

libmatt.com

libmatt.com