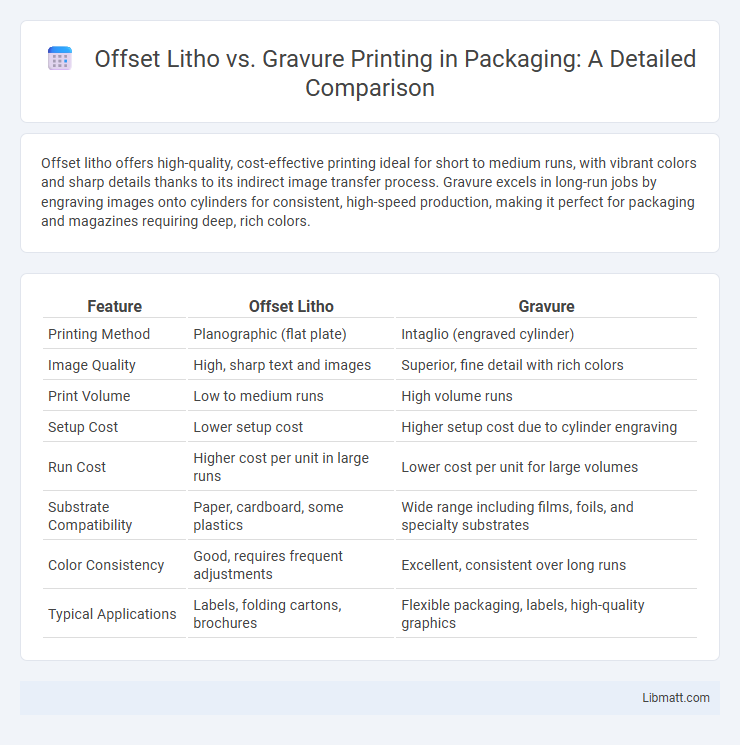

Offset litho offers high-quality, cost-effective printing ideal for short to medium runs, with vibrant colors and sharp details thanks to its indirect image transfer process. Gravure excels in long-run jobs by engraving images onto cylinders for consistent, high-speed production, making it perfect for packaging and magazines requiring deep, rich colors.

Table of Comparison

| Feature | Offset Litho | Gravure |

|---|---|---|

| Printing Method | Planographic (flat plate) | Intaglio (engraved cylinder) |

| Image Quality | High, sharp text and images | Superior, fine detail with rich colors |

| Print Volume | Low to medium runs | High volume runs |

| Setup Cost | Lower setup cost | Higher setup cost due to cylinder engraving |

| Run Cost | Higher cost per unit in large runs | Lower cost per unit for large volumes |

| Substrate Compatibility | Paper, cardboard, some plastics | Wide range including films, foils, and specialty substrates |

| Color Consistency | Good, requires frequent adjustments | Excellent, consistent over long runs |

| Typical Applications | Labels, folding cartons, brochures | Flexible packaging, labels, high-quality graphics |

Introduction to Offset Litho and Gravure

Offset lithography uses a flat printing plate where inked images are transferred to a rubber blanket before being applied to the printing surface, offering high-quality, cost-effective results for medium to large print runs. Gravure printing involves engraving an image onto a cylinder, which deposits ink directly onto the substrate, making it ideal for ultra-high-volume projects with rich, consistent color reproduction. Your choice between offset litho and gravure depends on factors like print volume, image quality requirements, and budget considerations.

Core Principles of Offset Litho Printing

Offset litho printing operates on the principle of oil and water repelling each other, where the image area attracts ink while the non-image area attracts water, preventing ink transfer. This method uses a flat printing plate with hydrophobic and hydrophilic regions to create precise, high-quality prints. The process involves transferring the inked image from the plate to a rubber blanket, then onto the printing surface, ensuring consistent, detailed reproduction ideal for diverse materials.

Gravure Printing: Process Overview

Gravure printing involves engraving the image onto a cylinder, where recessed cells hold the ink that transfers directly onto the substrate, enabling high-quality and consistent long-run prints. This process excels in producing fine details and rich color saturation, particularly suited for packaging, magazines, and wallpaper. The durability of the engraved cylinder allows cost-effective mass production with minimal maintenance, outperforming offset litho in continuous high-volume applications.

Key Differences Between Offset Litho and Gravure

Offset litho printing uses plates to transfer ink onto a rubber blanket before printing on paper, offering sharp images and cost-effective short to medium runs. Gravure printing involves engraving the image onto cylinders, enabling high-quality, continuous-tone images ideal for long print runs and packaging. Your choice depends on run length, image detail, and budget, with gravure excelling in durability and offset litho providing faster setup times.

Print Quality Comparison: Offset vs Gravure

Offset lithography delivers sharp, high-resolution images with consistent color fidelity, ideal for detailed text and fine line work. Gravure printing excels in producing rich, vibrant colors with smooth tonal gradients, making it superior for large runs of high-quality photo reproductions. While offset offers cost-effective short to medium runs with quick setup, gravure provides unmatched print quality for extensive production volumes due to its engraved cylinder process.

Cost Efficiency and Production Volume

Offset lithography offers lower setup costs and is more cost-efficient for short to medium print runs, typically up to 5,000 to 10,000 impressions, making it ideal for smaller production volumes. Gravure printing requires a higher initial investment due to expensive cylinder engraving but becomes more economical and cost-efficient for large production volumes exceeding 50,000 impressions through faster press speeds and consistent print quality. For high-volume projects like magazines and packaging, gravure delivers superior long-term cost efficiency despite higher upfront costs, whereas offset litho suits short-run jobs such as brochures and flyers.

Substrate Versatility and Ink Usage

Offset lithography offers greater substrate versatility, accommodating a wide range of surfaces including paper, cardboard, and plastic films, making it ideal for diverse printing applications. Gravure printing excels in high-volume runs with consistent image quality but is generally limited to flexible substrates like plastic and foil. Ink usage in offset litho is more efficient for shorter runs and variable images, while gravure uses high-viscosity inks that provide rich, vibrant colors suited for long print runs but with higher initial setup costs.

Environmental Impact of Both Techniques

Offset lithography generates less volatile organic compound (VOC) emissions due to its water-based inks and reusable plates, making it more environmentally friendly than gravure printing. Gravure printing consumes more energy and produces higher waste levels because of its complex cylinder etching and solvent-based inks. Recycling practices and the use of eco-friendly materials are crucial in minimizing the environmental footprint of both offset litho and gravure techniques.

Typical Applications and Industry Use Cases

Offset lithography is widely used in commercial printing sectors like newspapers, magazines, brochures, and packaging due to its cost-effectiveness for medium to large print runs and high image quality. Gravure printing excels in high-volume applications including flexible packaging, product labels, and decorative printing, offering superior ink transfer and durability. Industries such as publishing, advertising, food and beverage packaging, and cosmetics rely heavily on offset litho for detailed graphics, while gravure serves mass production needs in pharmaceuticals, tobacco, and wallpaper manufacturing.

Choosing the Right Printing Method

Choosing the right printing method depends on your project's volume, budget, and quality requirements. Offset litho excels in producing sharp images and is cost-effective for medium to large print runs with quick turnaround times. Gravure offers superior color depth and durability, making it ideal for high-volume applications like packaging and magazines where consistent image quality is essential.

Offset litho vs gravure Infographic

libmatt.com

libmatt.com