Roto-gravure printing offers high-speed production and superior image quality, ideal for large-volume runs and detailed graphics, while offset litho printing provides cost-effective versatility for medium-to-short print jobs with sharp text and vibrant colors. Choosing between these methods depends on your project's scale, budget, and required print quality.

Table of Comparison

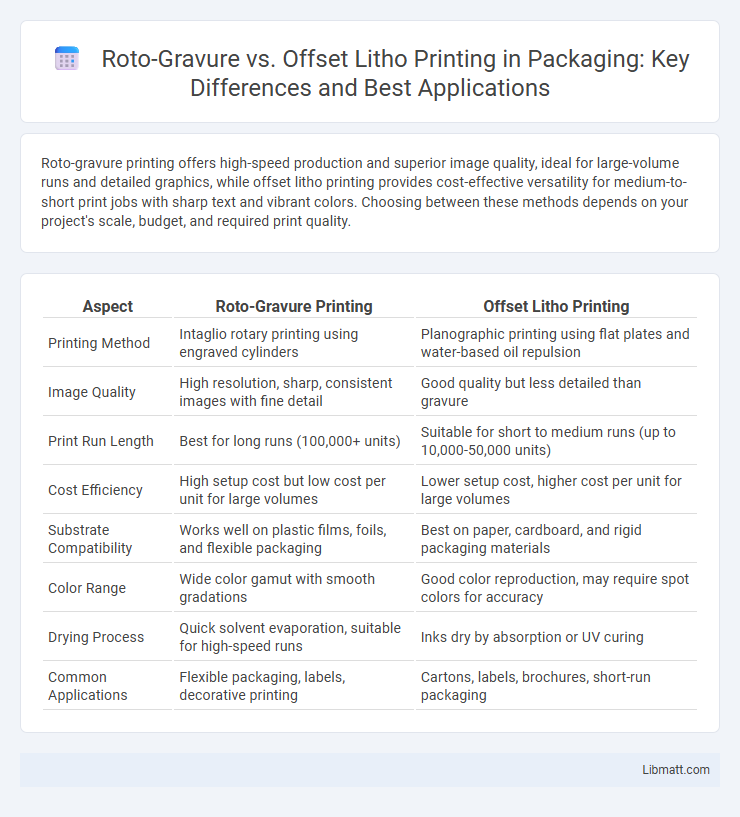

| Aspect | Roto-Gravure Printing | Offset Litho Printing |

|---|---|---|

| Printing Method | Intaglio rotary printing using engraved cylinders | Planographic printing using flat plates and water-based oil repulsion |

| Image Quality | High resolution, sharp, consistent images with fine detail | Good quality but less detailed than gravure |

| Print Run Length | Best for long runs (100,000+ units) | Suitable for short to medium runs (up to 10,000-50,000 units) |

| Cost Efficiency | High setup cost but low cost per unit for large volumes | Lower setup cost, higher cost per unit for large volumes |

| Substrate Compatibility | Works well on plastic films, foils, and flexible packaging | Best on paper, cardboard, and rigid packaging materials |

| Color Range | Wide color gamut with smooth gradations | Good color reproduction, may require spot colors for accuracy |

| Drying Process | Quick solvent evaporation, suitable for high-speed runs | Inks dry by absorption or UV curing |

| Common Applications | Flexible packaging, labels, decorative printing | Cartons, labels, brochures, short-run packaging |

Introduction to Roto-Gravure and Offset Litho Printing

Roto-gravure printing uses engraved cylinders to transfer ink onto materials, offering high-speed production with exceptional image quality and durability. Offset litho printing relies on a flat plate that transfers images onto a rubber blanket before printing on paper, ideal for sharp details and vibrant colors in medium to large print runs. Your choice between these methods depends on factors like print volume, image quality, and material type.

Key Differences Between Roto-Gravure and Offset Litho

Roto-gravure printing uses engraved cylinders to transfer ink onto substrates, offering high-speed production and superior image quality ideal for long runs, while offset litho printing employs flat plates and a rubber blanket to reproduce images, providing cost-effective short to medium runs with quick setup times. Roto-gravure excels in consistent ink application and durability for detailed designs, whereas offset litho allows greater flexibility in substrate types and colors with rapid turnaround. The choice between the two depends on factors like print volume, image precision, and budget constraints.

Printing Process Overview: Roto-Gravure

Roto-gravure printing involves engraving images onto a cylinder, allowing for high-speed production and consistent quality, particularly suited for long runs. This process transfers ink from recessed cells on the cylinder directly onto the substrate, ensuring vibrant colors and fine detail reproduction. Your choice of roto-gravure optimizes efficiency and precision for large-volume printing projects compared to offset litho methods.

Printing Process Overview: Offset Lithography

Offset lithography uses a flat printing plate where the image area attracts ink while the non-image area repels it, leveraging the immiscibility of oil and water. The inked image transfers from the plate to a rubber blanket before being pressed onto the printing surface, ensuring high-quality, precise prints. Your choice of offset litho printing provides advantages such as sharp detail and cost-efficiency for medium- to large-volume runs compared to roto-gravure's engraved cylinder process.

Image Quality and Print Detail Comparison

Roto-gravure printing delivers superior image quality with rich, continuous tones and fine detail due to its engraved cylinders allowing precise ink transfer, ideal for high-volume runs requiring consistent sharpness and depth. Offset lithography provides excellent print detail with smooth gradients but may show slight dot gain and less tonal depth compared to roto-gravure, making it suitable for shorter runs and varied substrates. For applications demanding ultra-fine image resolution and vibrant color saturation, roto-gravure outperforms offset litho printing in maintaining crisp, high-definition prints.

Suitable Print Materials and Applications

Roto-gravure printing excels in high-volume production of flexible packaging materials like plastic films, foils, and paper, delivering consistent, high-quality images ideal for labels, wallpapers, and decorative finishes. Offset litho printing is better suited for printing on rigid or flat substrates such as paper, cardboard, and certain plastics, making it the preferred choice for brochures, magazines, and packaging cartons. Your selection depends on the substrate type and application requirements, with roto-gravure favored for continuous roll materials and offset litho ideal for sheet-fed printing jobs.

Production Volume and Cost Efficiency

Roto-gravure printing excels in high-volume production runs due to its ability to produce consistent, high-quality images at rapid speeds, making it highly cost-efficient for large quantities. Offset litho printing is more cost-effective for short to medium print runs because of lower setup costs and faster plate preparation, offering flexibility for varied print volumes without significant expense. Your choice depends on balancing production volume with budget constraints to optimize cost efficiency.

Turnaround Time and Setup Considerations

Roto-gravure printing offers faster turnaround times for large-volume runs due to its continuous rotary process, making it ideal for high-speed production with minimal delays. Offset litho printing requires longer setup times because of plate creation and adjustments, but it provides greater flexibility for short to medium print runs and quick design changes. Your choice depends on balancing the need for rapid output with setup complexity, especially when project deadlines are tight.

Environmental Impact and Sustainability

Roto-gravure printing consumes more energy and solvent-based inks, leading to higher volatile organic compound (VOC) emissions, which can negatively impact air quality, while offset litho printing typically uses less energy and water-based inks, reducing environmental footprints. Waste generation in roto-gravure is significant due to long setup times and high cylinder production, whereas offset litho produces less waste and offers easier plate recycling options. Your choice between these methods affects sustainability goals, as offset litho printing generally provides a more eco-friendly solution.

Choosing the Right Printing Method for Your Needs

Roto-gravure printing excels in high-volume runs, offering superior image quality and consistent color due to its engraved cylinders, making it ideal for packaging and long-term projects. Offset litho printing provides greater flexibility and cost-efficiency for shorter runs, allowing quick color changes and sharp detail, perfect for brochures and business cards. Evaluating your print volume, budget, and desired print quality ensures you choose the right method tailored to your specific needs.

Roto-gravure vs offset litho printing Infographic

libmatt.com

libmatt.com