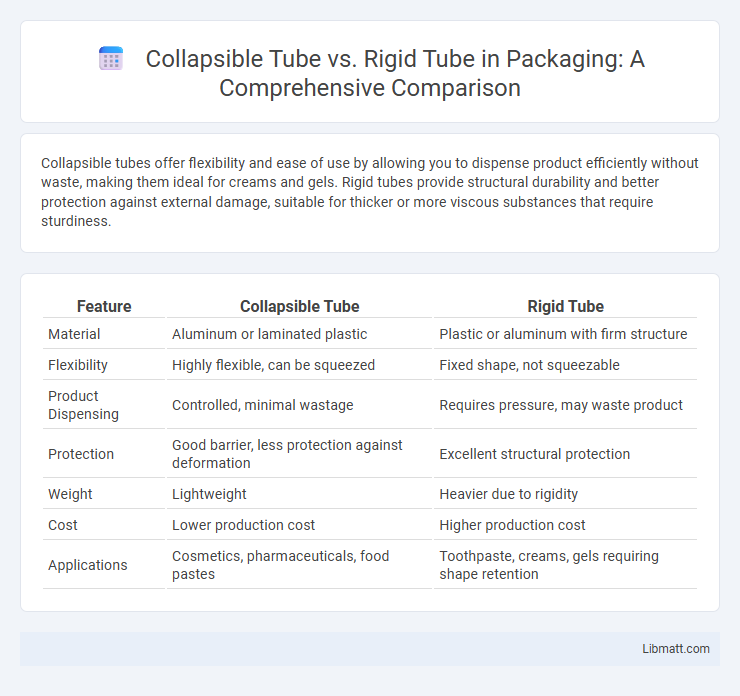

Collapsible tubes offer flexibility and ease of use by allowing you to dispense product efficiently without waste, making them ideal for creams and gels. Rigid tubes provide structural durability and better protection against external damage, suitable for thicker or more viscous substances that require sturdiness.

Table of Comparison

| Feature | Collapsible Tube | Rigid Tube |

|---|---|---|

| Material | Aluminum or laminated plastic | Plastic or aluminum with firm structure |

| Flexibility | Highly flexible, can be squeezed | Fixed shape, not squeezable |

| Product Dispensing | Controlled, minimal wastage | Requires pressure, may waste product |

| Protection | Good barrier, less protection against deformation | Excellent structural protection |

| Weight | Lightweight | Heavier due to rigidity |

| Cost | Lower production cost | Higher production cost |

| Applications | Cosmetics, pharmaceuticals, food pastes | Toothpaste, creams, gels requiring shape retention |

Introduction to Tube Packaging Types

Collapsible tubes, made from materials like aluminum or plastic laminate, provide flexible packaging ideal for creams, gels, and ointments, allowing precise dispensing and easy storage. Rigid tubes, typically crafted from hard plastic, offer robust protection and maintain shape for products such as toothpaste, lotions, and adhesives, ensuring durability and impact resistance. Your choice between collapsible and rigid tubes depends on product viscosity, required shelf life, and consumer convenience.

Overview of Collapsible Tubes

Collapsible tubes are flexible, typically made from materials like aluminum or laminate, designed to compress as the contents are dispensed, minimizing air exposure and product waste. They offer excellent portability and are commonly used for creams, ointments, adhesives, and food pastes due to their lightweight and ease of use. Unlike rigid tubes, collapsible tubes provide efficient storage by shrinking with product depletion, maintaining hygiene and extending shelf life.

Overview of Rigid Tubes

Rigid tubes, typically made from materials like aluminum, plastic, or glass, provide excellent protection and structural integrity for products such as cosmetics, pharmaceuticals, and adhesives. These tubes maintain their shape regardless of content volume, ensuring consistent dispensing and a premium look that enhances brand perception. Your choice of rigid tubes can improve product safety, shelf life, and customer experience due to their durability and resistance to deformation.

Material Differences: Collapsible vs Rigid Tubes

Collapsible tubes are typically made from flexible materials such as aluminum or laminated plastics that allow for easy squeezing and controlled dispensing, whereas rigid tubes often use high-density polyethylene (HDPE) or polypropylene (PP) for structural stability and resistance to deformation. The laminated layers in collapsible tubes provide barrier properties against moisture and oxygen, preserving sensitive contents like pharmaceuticals and cosmetics better than many rigid tubes. Material selection impacts recyclability, with rigid polyethylene tubes being more widely recycled compared to multi-layered collapsible tubes requiring specialized processing facilities.

Design and Versatility Comparison

Collapsible tubes offer flexible, lightweight designs ideal for squeezing out precise amounts of product, making them highly versatile for creams, gels, and pastes. Rigid tubes provide robust structural integrity and superior protection against external damage, suitable for products requiring a more durable packaging solution. Your choice between collapsible and rigid tubes should consider the balance between ease of use, product type, and packaging durability needs.

Ease of Use and Dispensing

Collapsible tubes offer superior ease of use by allowing precise control over the amount of product dispensed, minimizing waste and reducing contamination risks. Rigid tubes, while sturdier, often require more effort to extract product, especially as the contents near depletion, potentially leading to product wastage. The flexible nature of collapsible tubes enables smoother dispensing, making them ideal for viscous products and on-the-go usage.

Cost Implications of Each Tube Type

Collapsible tubes generally offer lower material and transportation costs due to their lightweight, flexible construction and efficient packing, reducing shipping volume and associated expenses. Rigid tubes tend to be more expensive because of the higher material usage and increased shipping costs from their bulkier, less space-efficient design. Choosing between collapsible and rigid tubes depends on budget constraints, production volume, and the desired balance between durability and cost-effectiveness.

Environmental Impact and Sustainability

Collapsible tubes significantly reduce environmental impact due to their lower material usage and lighter weight, resulting in decreased carbon emissions during transportation compared to rigid tubes. They are often made from recyclable plastics or aluminum, enhancing sustainability by enabling easier recycling processes. Your choice of packaging can contribute to waste reduction and support eco-friendly practices by favoring collapsible tubes over rigid alternatives.

Applications and Industry Preferences

Collapsible tubes are widely used in the cosmetics, pharmaceutical, and food industries due to their lightweight design, flexibility, and ease of dispensing small product amounts. Rigid tubes are favored in industrial applications such as adhesives, lubricants, and heavy-duty chemicals because of their durability, structural integrity, and ability to withstand harsh conditions. Industry preferences depend on product viscosity, protection requirements, and end-user convenience, making collapsible tubes ideal for personal care, while rigid tubes excel in technical and industrial environments.

Which Tube is Right for Your Product?

Collapsible tubes offer precise dispensing and protect contents from contamination, making them ideal for creams, gels, and adhesives requiring controlled application and minimal waste. Rigid tubes provide superior durability and structural integrity, suitable for products needing robust packaging, such as thicker pastes or heavy-duty ointments. Choosing between collapsible and rigid tubes depends on product viscosity, dispensing needs, and shelf appeal to ensure optimal preservation and user experience.

Collapsible tube vs rigid tube Infographic

libmatt.com

libmatt.com