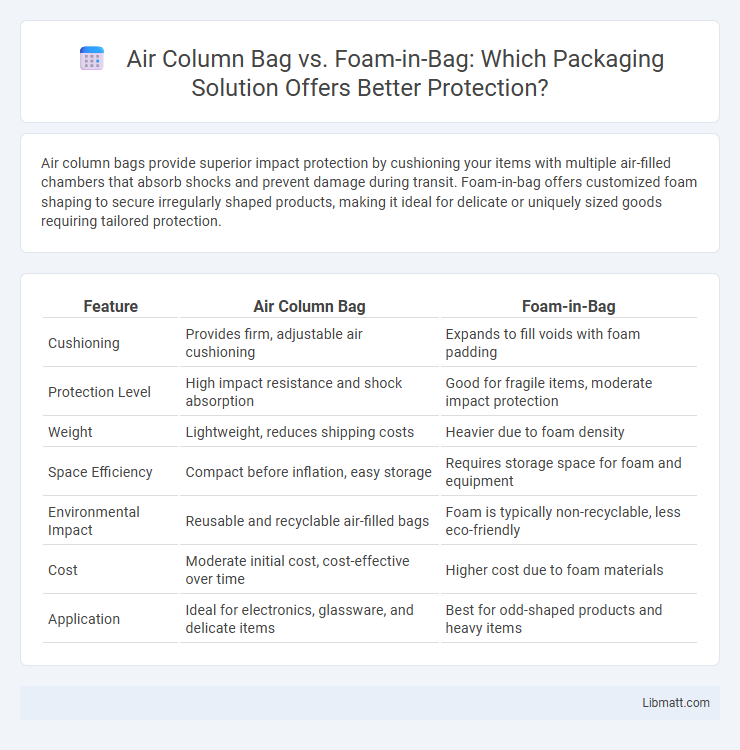

Air column bags provide superior impact protection by cushioning your items with multiple air-filled chambers that absorb shocks and prevent damage during transit. Foam-in-bag offers customized foam shaping to secure irregularly shaped products, making it ideal for delicate or uniquely sized goods requiring tailored protection.

Table of Comparison

| Feature | Air Column Bag | Foam-in-Bag |

|---|---|---|

| Cushioning | Provides firm, adjustable air cushioning | Expands to fill voids with foam padding |

| Protection Level | High impact resistance and shock absorption | Good for fragile items, moderate impact protection |

| Weight | Lightweight, reduces shipping costs | Heavier due to foam density |

| Space Efficiency | Compact before inflation, easy storage | Requires storage space for foam and equipment |

| Environmental Impact | Reusable and recyclable air-filled bags | Foam is typically non-recyclable, less eco-friendly |

| Cost | Moderate initial cost, cost-effective over time | Higher cost due to foam materials |

| Application | Ideal for electronics, glassware, and delicate items | Best for odd-shaped products and heavy items |

Overview: Air Column Bag vs Foam-in-Bag

Air column bags are inflatable packaging solutions designed to provide high-impact resistance and cushioning by using multiple air chambers that absorb shocks during transit. Foam-in-bag packaging consists of expandable foam sealed within a plastic bag, which molds around the product to offer custom protection and fill voids in shipping boxes. Both methods enhance product safety, but air column bags provide reusable and lightweight protection, whereas foam-in-bag offers versatile, form-fitting cushioning ideal for irregularly shaped items.

How Air Column Bags Work

Air column bags utilize multiple inflated air chambers that provide superior cushioning by absorbing shocks and impacts during transit. These chambers are designed to distribute pressure evenly, protecting fragile items from damage effectively. Your products remain secure with this lightweight, flexible packaging solution that molds closely to the shape of your goods.

How Foam-in-Bag Packaging Functions

Foam-in-bag packaging functions by injecting a two-part foam mixture into an inflatable bag that expands and hardens around your product, providing customized cushioning and protection. This technology ensures a snug fit, preventing movement and absorbing shocks during transportation. Compared to air column bags, foam-in-bag packaging offers superior impact resistance and adaptability for irregularly shaped items.

Key Differences Between Air Column and Foam-in-Bag

Air column bags provide superior shock absorption through multiple air-filled chambers that cushion delicate items, while foam-in-bag offers customizable foam expansion tailored to irregularly shaped products. Air column bags are lightweight and reusable, making them ideal for protecting fragile electronics during shipping, whereas foam-in-bag creates a dense and stable buffer more suited for heavy or oddly shaped goods. Understanding these key differences helps you select the optimal packaging solution based on your product's fragility, shape, and shipping requirements.

Protection Levels and Shock Absorption

Air column bags provide superior shock absorption by inflating multiple air tubes around the product, creating a cushioned barrier that effectively disperses impact forces. Foam-in-bag offers consistent protection with a dense foam material that molds around items, absorbing shocks and preventing direct contact with external surfaces. While air column bags excel in flexibility and lightweight protection, foam-in-bag delivers reliable padding best suited for irregularly shaped or heavier objects.

Space Efficiency and Storage Needs

Air column bags offer superior space efficiency by inflating only upon use, reducing overall storage volume compared to foam-in-bag materials that require bulky pre-storage space. Foam-in-bag systems occupy fixed storage footprints and contribute to higher warehouse space demands, whereas air column technology optimizes inventory management with compact flat storage before inflation. This distinction makes air column bags ideal for businesses focused on minimizing storage costs and maximizing packaging flexibility.

Environmental Impact and Sustainability

Air column bags offer a more sustainable packaging solution by using less material and requiring less energy to produce compared to foam-in-bag systems, which generate more non-biodegradable waste. Your choice of air column bags can reduce carbon footprint due to their lightweight nature and recyclability, while foam-in-bag often contributes to landfill accumulation and is harder to recycle. Prioritizing air column bags supports environmental impact reduction through minimized resource consumption and enhanced recyclability.

Cost Comparison: Air Column vs Foam-in-Bag

Air column bags typically offer cost savings due to their lightweight design, reducing shipping expenses by minimizing dimensional weight charges compared to foam-in-bag packaging. Foam-in-bag materials often have a higher initial purchase price and can increase package weight, leading to elevated transportation costs. Overall, air column bags provide a more economical solution for businesses prioritizing both packaging protection and reduced shipping fees.

Application Suitability for Various Industries

Air column bags provide superior protection and cushioning, making them highly suitable for fragile electronics, glassware, and medical supplies requiring shock absorption. Foam-in-bag packaging offers versatility and conforms easily to irregularly shaped products, ideal for automotive parts, hardware, and industrial components. Your choice depends on the specific requirements of product protection, shape conformity, and industry standards.

Choosing the Right Packaging Solution

Air column bags provide superior cushioning through multiple air chambers that absorb impact effectively, making them ideal for fragile electronics and glassware. Foam-in-bag packaging offers customizable thickness and conforms to odd-shaped items, ensuring comprehensive protection during transit. Selecting between these options depends on product fragility, shape complexity, and shipping conditions to optimize damage prevention and cost-efficiency.

Air column bag vs foam-in-bag Infographic

libmatt.com

libmatt.com