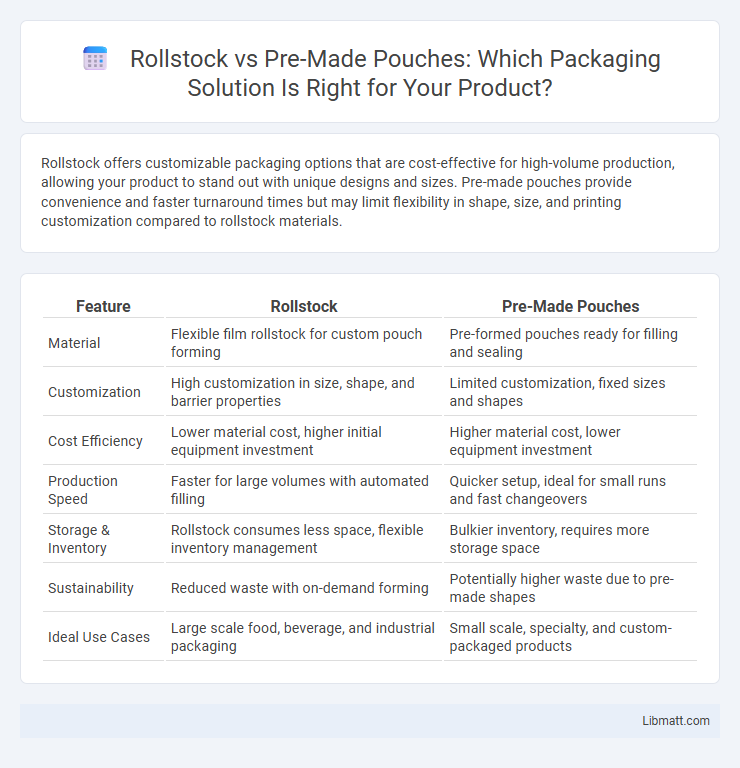

Rollstock offers customizable packaging options that are cost-effective for high-volume production, allowing your product to stand out with unique designs and sizes. Pre-made pouches provide convenience and faster turnaround times but may limit flexibility in shape, size, and printing customization compared to rollstock materials.

Table of Comparison

| Feature | Rollstock | Pre-Made Pouches |

|---|---|---|

| Material | Flexible film rollstock for custom pouch forming | Pre-formed pouches ready for filling and sealing |

| Customization | High customization in size, shape, and barrier properties | Limited customization, fixed sizes and shapes |

| Cost Efficiency | Lower material cost, higher initial equipment investment | Higher material cost, lower equipment investment |

| Production Speed | Faster for large volumes with automated filling | Quicker setup, ideal for small runs and fast changeovers |

| Storage & Inventory | Rollstock consumes less space, flexible inventory management | Bulkier inventory, requires more storage space |

| Sustainability | Reduced waste with on-demand forming | Potentially higher waste due to pre-made shapes |

| Ideal Use Cases | Large scale food, beverage, and industrial packaging | Small scale, specialty, and custom-packaged products |

Understanding Rollstock and Pre-Made Pouches

Rollstock consists of flexible packaging material supplied in a roll form that manufacturers convert into pouches during the packaging process, offering customization in size and design. Pre-made pouches are fully formed packaging units ready for filling and sealing, providing quicker setup times and consistency in shape. Choosing between rollstock and pre-made pouches depends on production volume, packaging equipment, and design flexibility requirements.

Key Differences Between Rollstock and Pre-Made Pouches

Rollstock offers flexible packaging material in continuous rolls, allowing customization in pouch size and design, while pre-made pouches come as fixed-size, ready-to-fill packages. Rollstock typically reduces material waste and storage space, enhancing efficiency in automated filling operations, whereas pre-made pouches simplify handling but may increase inventory complexity. Your choice depends on production volume, packaging speed, and the need for customization versus convenience.

Cost Efficiency: Rollstock vs Pre-Made Pouches

Rollstock packaging offers superior cost efficiency due to lower material costs and reduced shipping expenses, as rollstock takes up less space and minimizes storage requirements. Pre-made pouches typically incur higher costs from individual pouch manufacturing, longer production setup times, and greater transportation volume. For high-volume production, rollstock significantly reduces per-unit costs by optimizing material use and streamlining the packaging process.

Production Speed and Flexibility

Rollstock packaging offers faster production speeds due to continuous web processing, minimizing machine downtime compared to pre-made pouches that require individual loading. Rollstock systems provide greater flexibility in customizing pouch shapes, sizes, and barrier properties directly on the line, enabling quick adjustments for different product runs. Pre-made pouches, while simpler to use, often limit speed and adaptability because each pouch must be pre-formed, impacting overall packaging efficiency.

Customization and Design Capabilities

Rollstock offers superior customization and design capabilities, allowing you to tailor packaging dimensions, materials, and graphics to your specific brand needs. Pre-made pouches come with fixed sizes and designs, limiting flexibility in branding and product presentation. Choosing rollstock enhances your ability to create unique, eye-catching packaging that aligns perfectly with your marketing strategy.

Packaging Equipment Requirements

Rollstock packaging requires specialized equipment such as form-fill-seal machines that can handle large rolls of flexible film, allowing customization in pouch size and design. Pre-made pouches need different machinery, including pouch fillers and sealers, tailored specifically for pre-formed bags, often enabling faster changeovers and less material waste. Your choice depends on production scale, available equipment investment, and desired packaging flexibility.

Environmental Impact and Sustainability

Rollstock packaging reduces waste by being produced on-demand, minimizing excess inventory and material use, which enhances sustainability compared to pre-made pouches. Pre-made pouches often result in higher transportation emissions due to bulk shipping and require more storage space, increasing the overall environmental footprint. Choosing rollstock materials with recyclable or biodegradable properties further supports eco-friendly packaging solutions by reducing landfill contributions.

Application Suitability: Choosing the Right Solution

Rollstock offers flexibility for customizing packaging sizes and designs, making it ideal for brands with variable product lines or frequent packaging updates. Pre-made pouches provide efficient, consistent quality and faster production setup, suitable for high-volume runs with stable product specifications. Your choice depends on balancing customization needs against production speed and cost efficiency.

Quality and Consistency Considerations

Rollstock packaging offers superior quality control through on-demand forming, minimizing exposure to contaminants and allowing precise customization of material layers for consistent barrier properties. Pre-made pouches provide uniform factory-manufactured quality but may face variability in sealing strength and material integrity due to handling and storage conditions. Manufacturers prioritize rollstock for high-consistency production runs requiring tailored specifications, while pre-made pouches suit applications favoring convenience over fine-tuned quality control.

Rollstock or Pre-Made Pouches: Which Is Best for Your Business?

Rollstock offers flexibility and cost efficiency for businesses with high-volume or customized packaging needs, allowing you to create pouches on-demand and reduce inventory costs. Pre-made pouches provide consistent quality and faster setup times, ideal for smaller batches or companies prioritizing convenience and speed. Evaluating your production scale, design requirements, and budget will help determine whether rollstock or pre-made pouches best support your packaging strategy.

Rollstock vs pre-made pouches Infographic

libmatt.com

libmatt.com