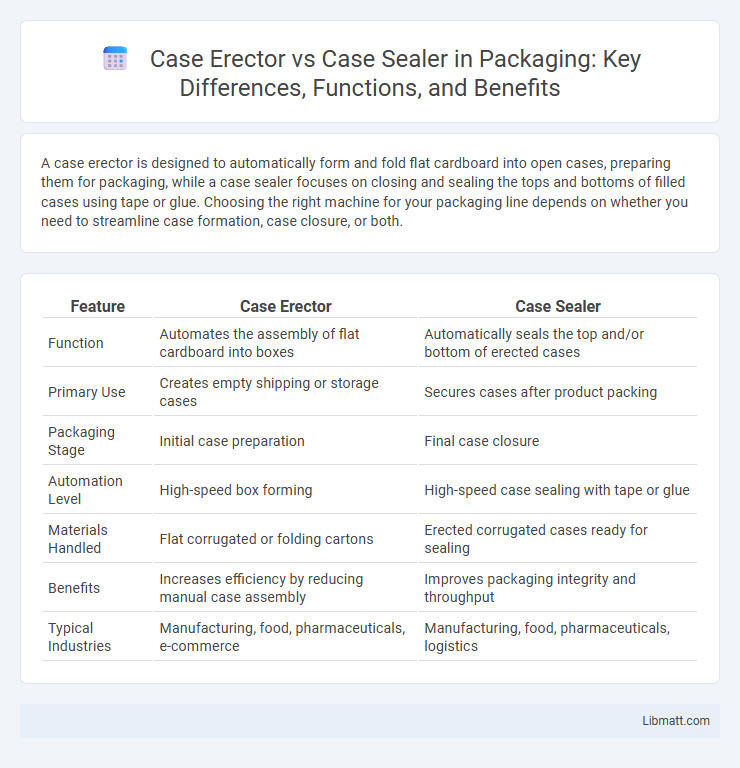

A case erector is designed to automatically form and fold flat cardboard into open cases, preparing them for packaging, while a case sealer focuses on closing and sealing the tops and bottoms of filled cases using tape or glue. Choosing the right machine for your packaging line depends on whether you need to streamline case formation, case closure, or both.

Table of Comparison

| Feature | Case Erector | Case Sealer |

|---|---|---|

| Function | Automates the assembly of flat cardboard into boxes | Automatically seals the top and/or bottom of erected cases |

| Primary Use | Creates empty shipping or storage cases | Secures cases after product packing |

| Packaging Stage | Initial case preparation | Final case closure |

| Automation Level | High-speed box forming | High-speed case sealing with tape or glue |

| Materials Handled | Flat corrugated or folding cartons | Erected corrugated cases ready for sealing |

| Benefits | Increases efficiency by reducing manual case assembly | Improves packaging integrity and throughput |

| Typical Industries | Manufacturing, food, pharmaceuticals, e-commerce | Manufacturing, food, pharmaceuticals, logistics |

Introduction to Case Erectors and Case Sealers

Case erectors automate the process of forming cardboard boxes from flat sheets, increasing packaging efficiency and consistency in your production line. Case sealers apply adhesive or tape to securely close erected boxes, ensuring products remain protected during storage and shipment. Together, these machines streamline packaging operations by reducing manual labor and enhancing overall workflow productivity.

What is a Case Erector?

A case erector is an automated packaging machine designed to fold flat corrugated cardboard sheets into open boxes ready for filling. It increases production efficiency by precisely forming cases at high speeds, reducing manual labor and error. Typically used in manufacturing and distribution centers, case erectors prepare cartons for packaging products before sealing.

What is a Case Sealer?

A case sealer is a packaging machine designed to close and seal the flaps of cardboard boxes after they have been erected and filled. It typically uses adhesive tape or glue to ensure the boxes are securely sealed for shipping or storage, enhancing efficiency in packaging lines. Case sealers optimize the final stage of box preparation, complementing case erectors that form the boxes initially.

Key Differences Between Case Erectors and Case Sealers

Case erectors automate the process of forming flat cardboard into sturdy, square cases ready for packaging, significantly improving setup speed and reducing manual labor. Case sealers focus on sealing the tops and bottoms of pre-formed cases using adhesive tape or glue, ensuring secure closure and protection during shipment. The primary differences lie in their functions: erectors create the box structure, whereas sealers finalize and secure the package for transport.

Functions and Applications of Case Erectors

Case erectors automate the process of assembling flat cardboard into rigid boxes, significantly enhancing packaging line efficiency and reducing labor costs. These machines are essential in industries where high-speed production and consistent box formation are critical, such as food, pharmaceuticals, and electronics. By ensuring precise case erection, your packaging operations maintain product protection and streamline downstream processes like filling and sealing.

Functions and Applications of Case Sealers

Case sealers automate the process of securely sealing cartons with adhesive tape or glue, enhancing packaging efficiency and consistency in manufacturing lines. They are predominantly used in industries with high-volume packing requirements such as food and beverage, pharmaceuticals, and electronics to ensure product protection and reduce manual labor. Unlike case erectors, which form flat cartons into boxes, case sealers focus exclusively on closing and sealing the top or bottom flaps of pre-erected cases for final shipment.

Benefits of Using Case Erectors

Case erectors automate the process of forming and folding cardboard boxes, significantly increasing packaging speed and consistency compared to manual methods. They reduce labor costs and minimize errors by precisely shaping cases ready for filling, enhancing your production line efficiency. Using a case erector ensures uniform box quality, which protects products better and streamlines downstream packaging operations.

Benefits of Using Case Sealers

Case sealers enhance packaging efficiency by automating the closure process, ensuring consistent and secure sealing. They reduce labor costs and minimize human error, leading to improved productivity and product protection. Enhanced sealing quality from case sealers helps prevent shipping damage and maintains product integrity during transit.

Factors to Consider When Choosing Between Case Erectors and Case Sealers

Selecting between case erectors and case sealers requires evaluating production speed, as erectors rapidly form boxes from flat sheets while sealers focus on efficiently closing filled boxes. Consider the level of automation and compatibility with existing packaging lines to optimize workflow and reduce manual labor. Additionally, assess material type and box size variability to ensure the equipment can handle specific packaging requirements without compromising sealing integrity or accuracy.

Choosing the Right Solution for Your Packaging Line

Choosing between a case erector and a case sealer depends on your packaging line's specific needs for automation and efficiency. Case erectors automatically form and seal the bottoms of corrugated boxes, preparing them for product loading, while case sealers focus on sealing the tops of filled cases to ensure secure shipping. Understanding Your production volume, box size variability, and desired speed helps determine the optimal equipment to streamline Your packaging process and reduce manual labor.

Case erector vs case sealer Infographic

libmatt.com

libmatt.com